Array substrate, display panel and display device

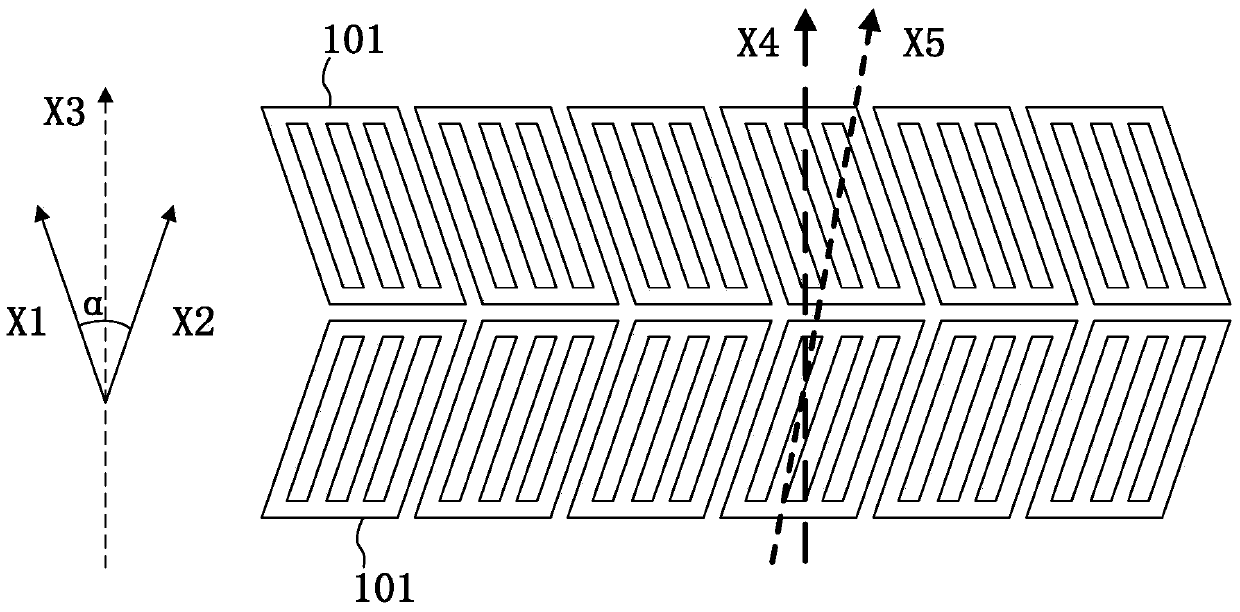

An array substrate and matrix technology, applied in the display field, can solve problems such as uneven brightness of odd-numbered and even-numbered rows, horizontal stripes of liquid crystal display devices, skewed polarizers, etc., and achieve the effect of avoiding the problem of horizontal stripes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] Based on the above description, Embodiment 1 of the present invention provides the following solution.

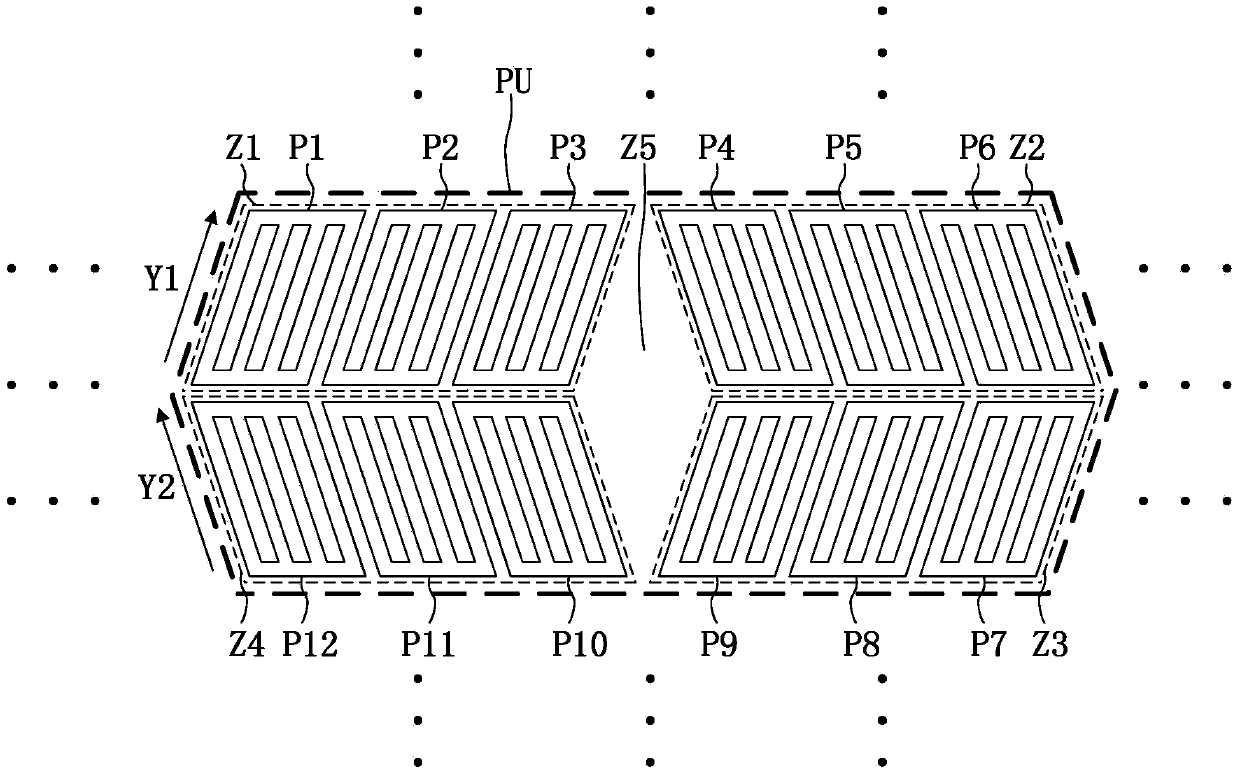

[0047] Embodiment 1 of the present invention provides an array substrate. Figure 1b It is a schematic structural diagram of an array substrate provided in Embodiment 1 of the present invention. see Figure 1b, the array substrate includes: a plurality of pixel units PU, the pixel unit PU includes a 2×2 sub-pixel region matrix, and the 2×2 sub-pixel region matrix includes a first sub-pixel region Z1, a second sub-pixel region arranged in sequence The pixel area Z2, the third sub-pixel area Z3 and the fourth sub-pixel area Z4; each of the sub-pixel areas includes three sub-pixel electrodes; each of the sub-pixel electrodes includes a strip electrode; the first sub-pixel Each of the zone Z1 and the third sub-pixel zone Z3 has at least one sub-pixel electrode in which the strip electrode is parallel to the first direction Y1; the second sub-pixel zone Z2 and the fourt...

Embodiment 2

[0059] exist Figure 1b In the pixel unit shown, the strip electrodes in all the sub-pixel electrodes in the first sub-pixel area Z1 and the third sub-pixel area Z3 are parallel to the first direction Y1, and the second sub-pixel area Z2 and the fourth sub-pixel area The strip electrodes in all the sub-pixel electrodes in Z4 are parallel to the second direction Y2. For such a pixel unit, among the sub-pixel electrodes in the same row, the number of sub-pixel electrodes where the strip electrodes parallel to the first direction Y1 are located and the number of sub-pixel electrodes where the strip electrodes parallel to the second direction Y2 are located equal, if the rubbing alignment direction deviates during rubbing or the polarizer is skewed during attachment, then the brightness corresponding to the sub-pixel electrodes in the same row presents a relatively uniform distribution of bright and dark, and the adjacent two sub-pixel electrodes in the same column The parallel d...

Embodiment 3

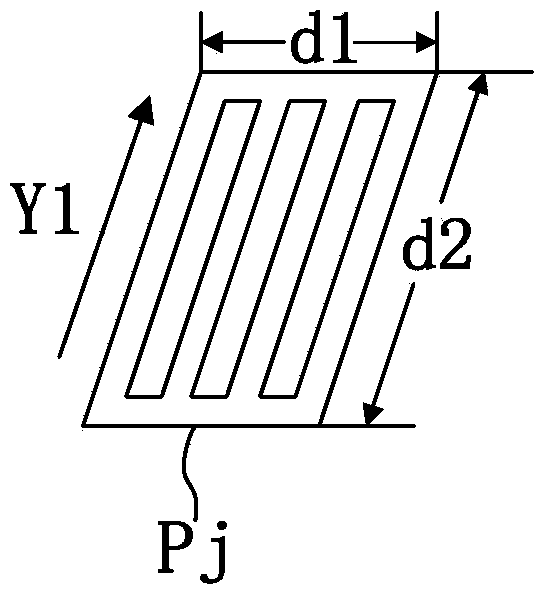

[0063] Figure 3a It is a schematic structural diagram of a pixel unit provided by Embodiment 3 of the present invention. see Figure 3a , on the basis of the structure of the array substrate described in Embodiment 1, the pixel unit on the array substrate of this embodiment may further be: the four sub-pixel regions respectively include three sub-pixel electrodes, each of the four sub-pixel regions It includes a 1×3 sub-pixel electrode matrix; each of the first sub-pixel region Z1 and the third sub-pixel region Z3 has a sub-pixel electrode in which the strip electrodes are parallel to the first direction Y1; Each of the second sub-pixel region Z2 and the fourth sub-pixel region Z4 has one sub-pixel electrode in which the strip electrode is parallel to the second direction Y2; the pixel unit includes two first regions ( Z5 and Z6).

[0064] see Figure 3a Specifically, the strip electrodes in the first subpixel electrode P1 and the seventh subpixel electrode P7 are paralle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com