Device for exerting force on a roll of a fiber web processing machine

An application device, fiber web technology, applied in the field of applying force on components of fiber web processing machines, to achieve the effect of preventing downtime, saving costs and avoiding the problem of cross stripes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

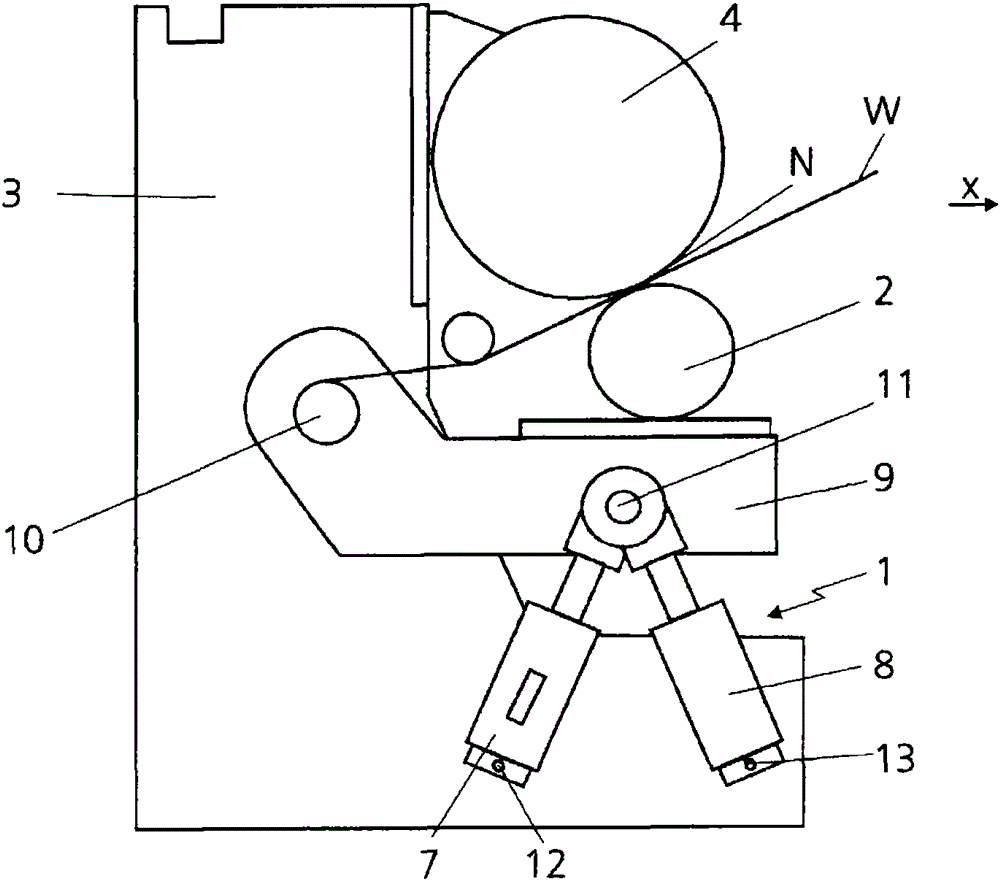

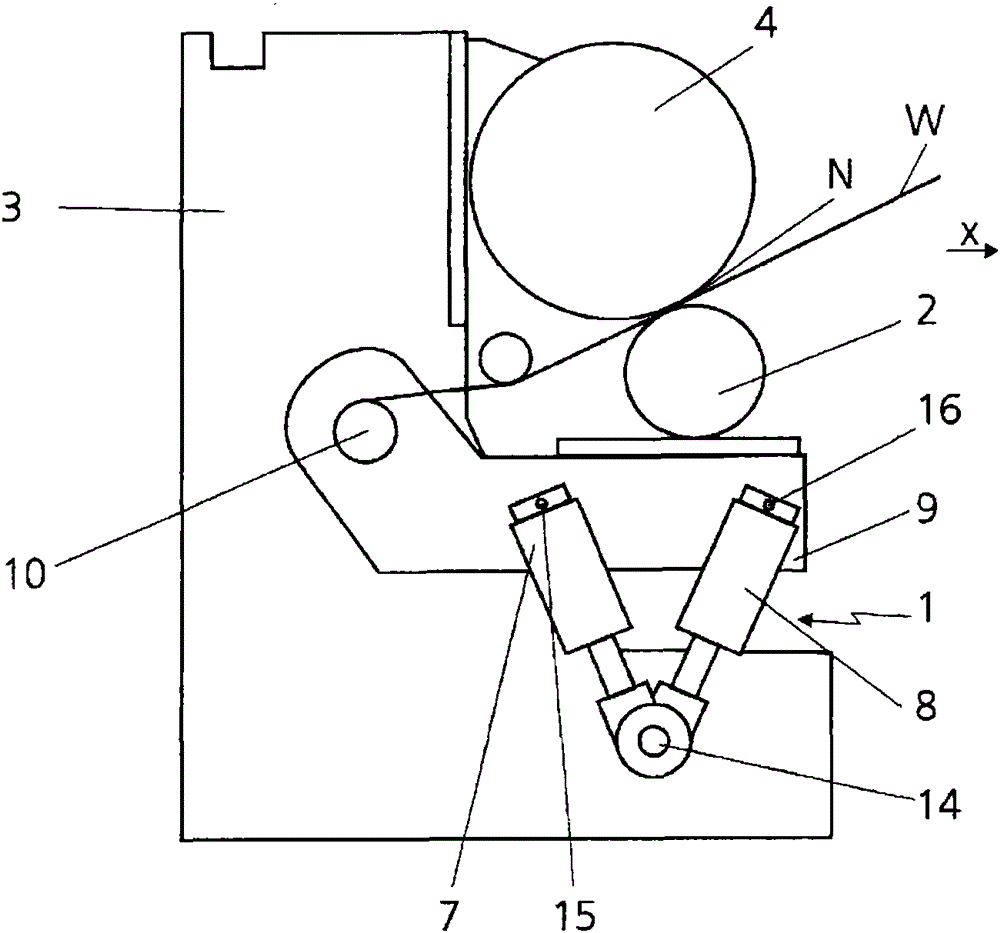

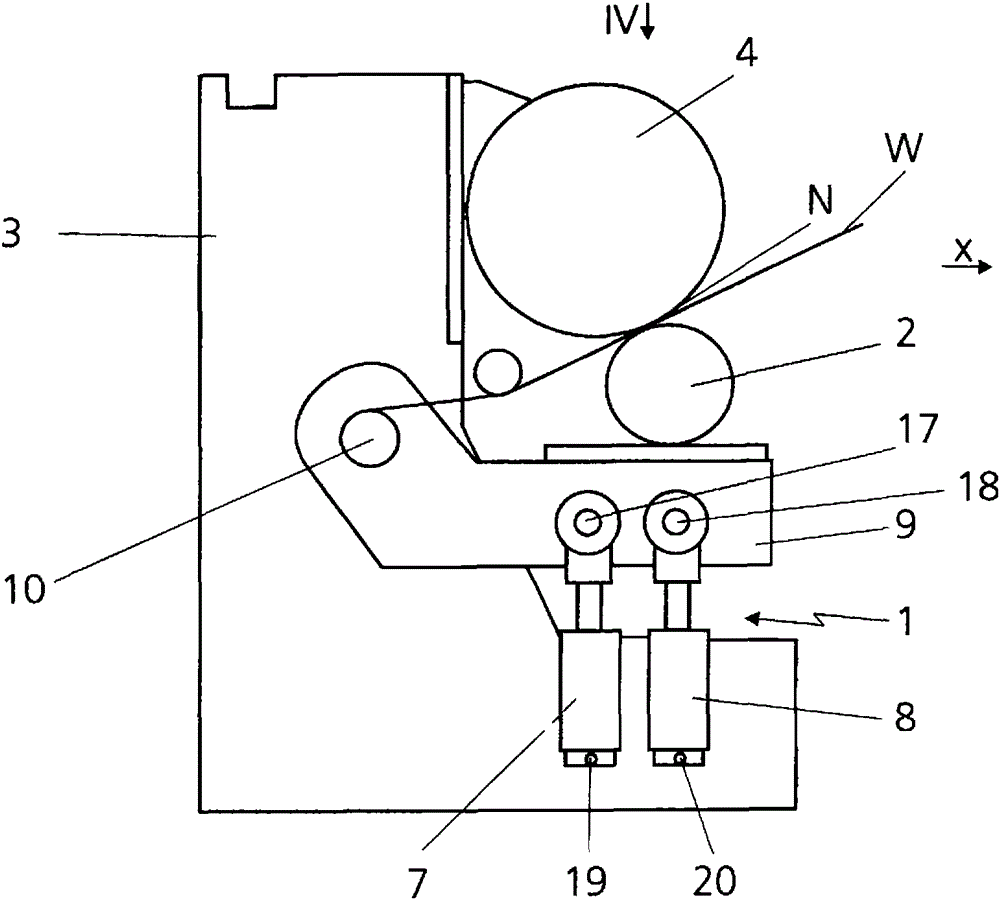

[0023] figure 1 A device 1 for exerting a force on a component of a fiber web processing machine, not shown in its entirety, which is configured as a roll 2 in this embodiment, is shown. The fibrous web processing machine may for example be a paper, board or tissue machine with which the fibrous web W is produced. In this embodiment, the roll 2 is part of a processing plant of a fiber web processing machine configured as a calender 3 . In addition to the calender 3, the treatment equipment can also be a drying section, a coating station, a dewatering unit or other similar treatment equipment. In addition to the roll 2 the calender 3 also has a further roll 4 , but further rolls can also be present in the calender 3 . In particular, the calender 3 can be designed as a multi-roll calender, it being immaterial at what angle the individual rolls are arranged relative to one another.

[0024] Between the two rolls 2 and 4 of the calender 3 a roll nip N is formed, through which t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com