Aircraft engine gas path fault fusion diagnosis method

A technology of aero-engine and diagnosis method, which is applied in the direction of engine testing, machine/structural component testing, special data processing application, etc., which can solve the problem that it is difficult to reflect the real state of the engine, it is difficult to obtain accurate estimation of engine component performance parameters, and sensor measurement Value drift and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The technical scheme of the present invention will be further described in detail below in conjunction with the accompanying drawings:

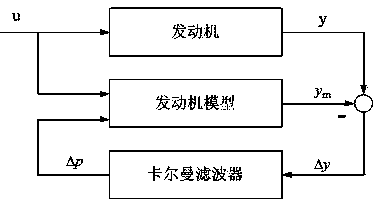

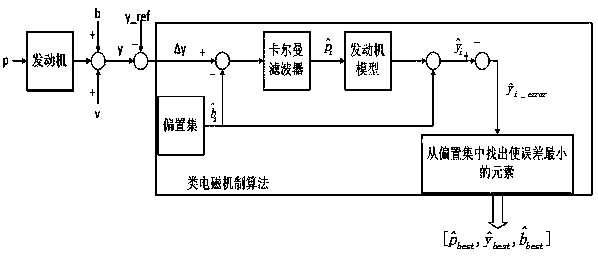

[0051] The specific implementation of the present invention takes the health diagnosis of a certain type of engine's gas path components as an example, such as figure 1 The diagnosis structure diagram of the present invention introduces a set of health parameters representing the health status of engine components to simulate performance degradation and performance mutations of engine components. The essence of diagnosis is to use engine sensor measurement values and state variable model output values The difference is combined with the Kalman filter algorithm to estimate the component health parameter changes, and the engine gas path component health diagnosis is transformed into a parameter estimation problem of component health parameter changes.

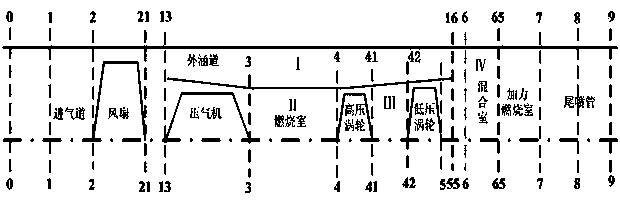

[0052] The working section identification diagram of a certain type of engine gas circui...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com