Aircraft turbojet engine exhaust cone

A gas jet, cone technology, applied in the direction of machines/engines, aircraft parts, jet propulsion devices, etc., can solve problems such as long time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] In the ensuing description the terms "front" and "rear" will be used.

[0044] The above terms are to be understood relative to the direction of air circulation in the nacelle when the turbojet engine is in operation.

[0045] More specifically, the front and rear are located on the left and right sides of each drawing, respectively.

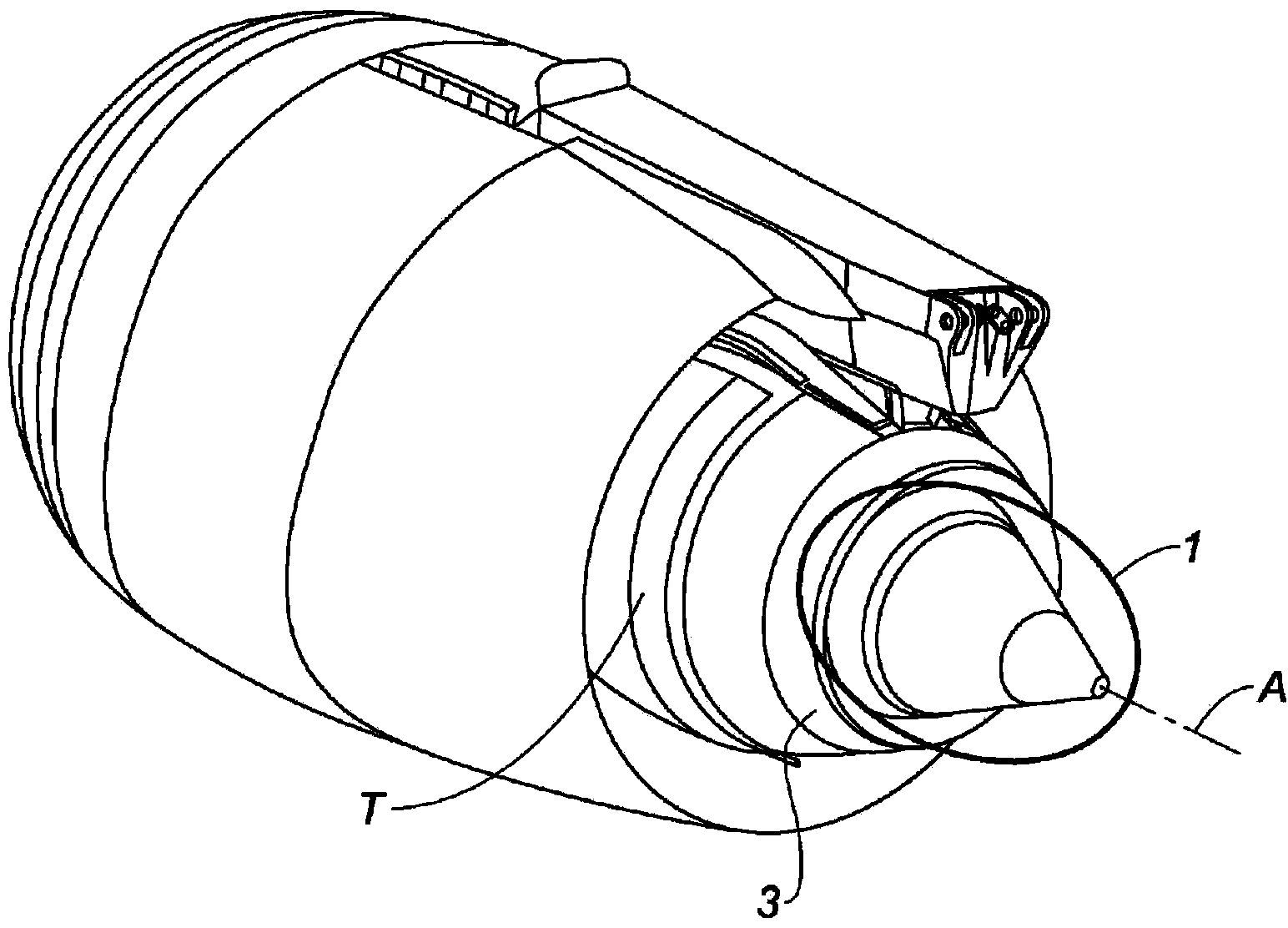

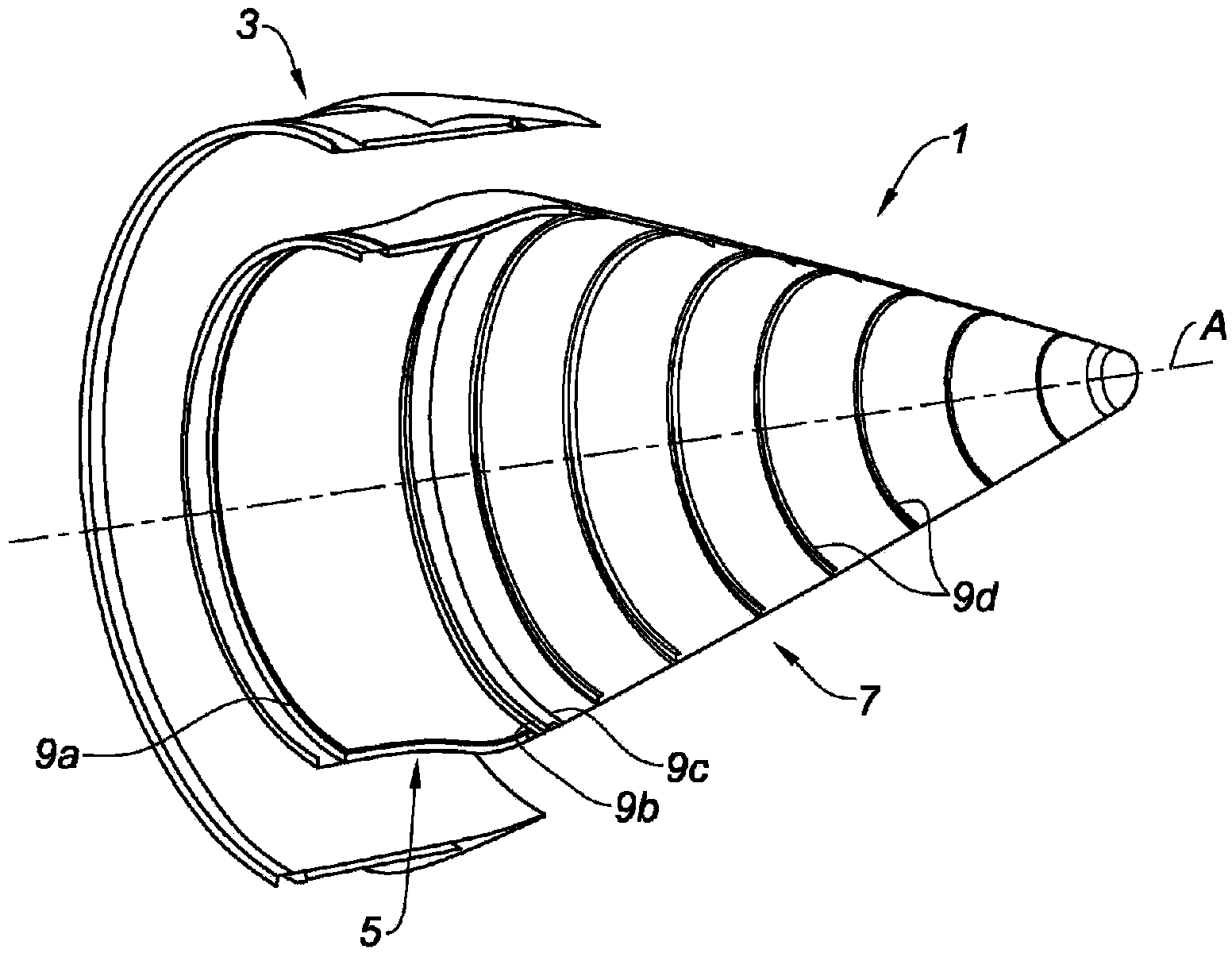

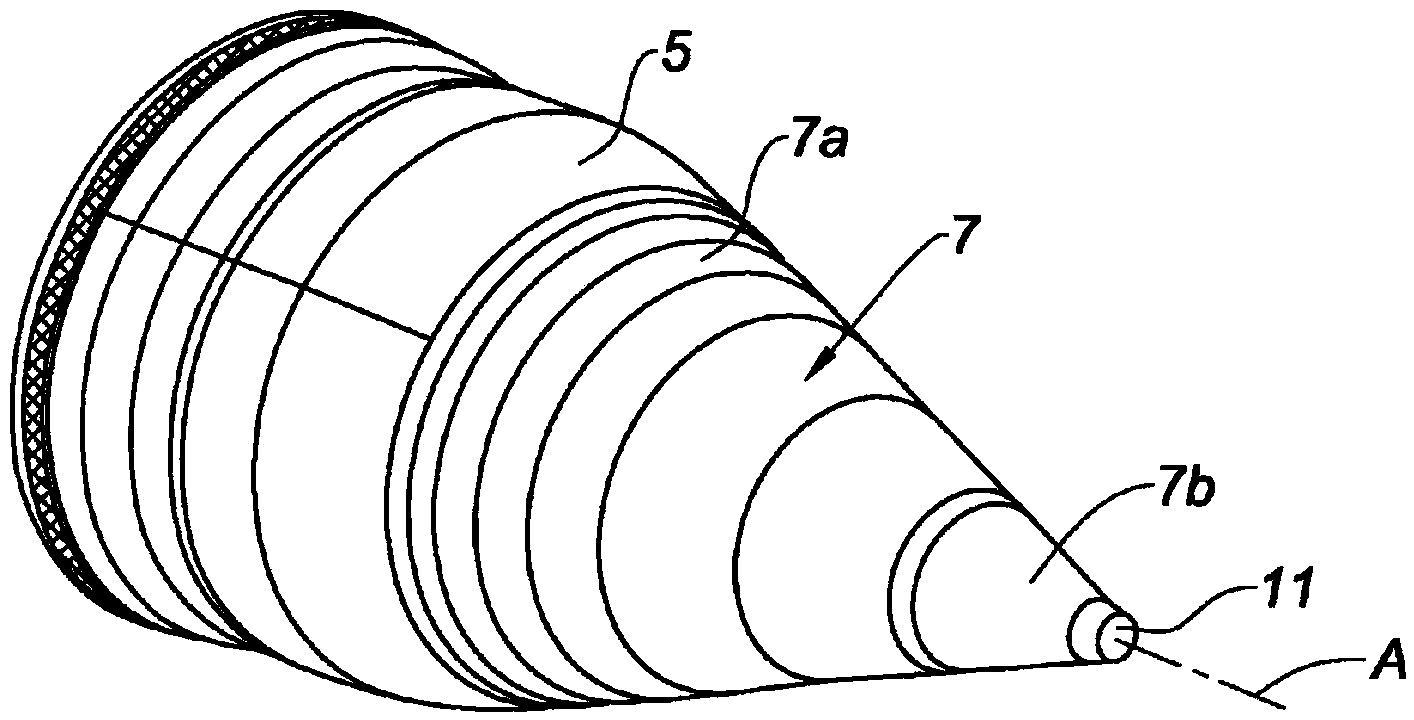

[0046] image 3 and Figure 4 The spray cone 1 according to the invention is shown comprising two main parts, namely a substantially cylindrical front cone part 5 and a substantially conical rear cone part 7 .

[0047] As mentioned earlier in the description, the front cone portion 5 and the rear cone portion 7 may be non-detachably connected to each other, such as by welding, or may be detachably connected to each other, such as by screws, as image 3 and Figure 4 Example shown.

[0048] The rear cone portion 7 sequentially includes a front sub-section 7a and a rear sub-section 7b detachably connected thereto, for example, by screw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com