Axial flow ventilation or diagonal flow ventilation

An axial flow and diagonal flow technology, applied in the field of rotating wheels, to achieve the effect of reducing noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

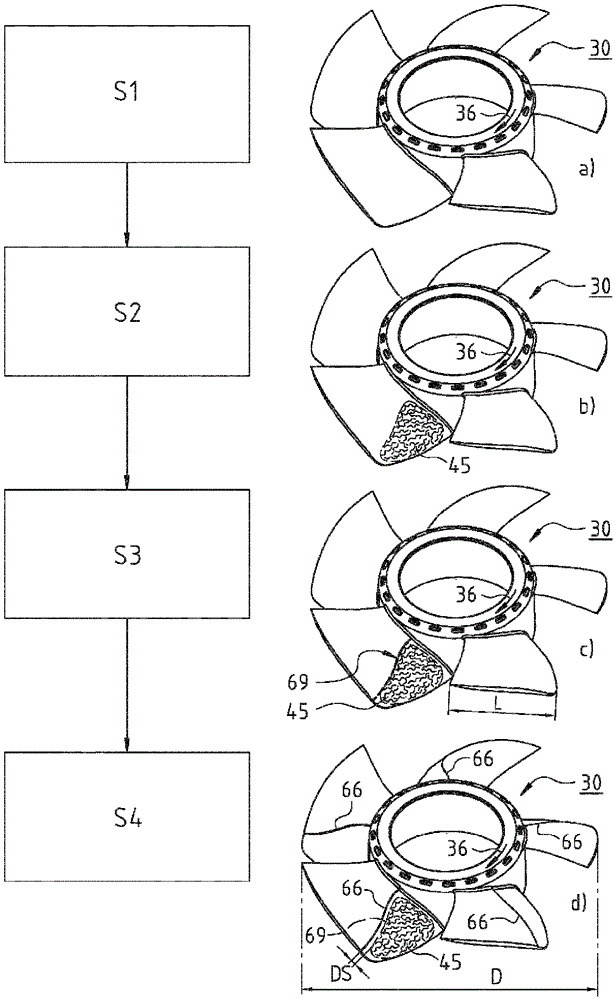

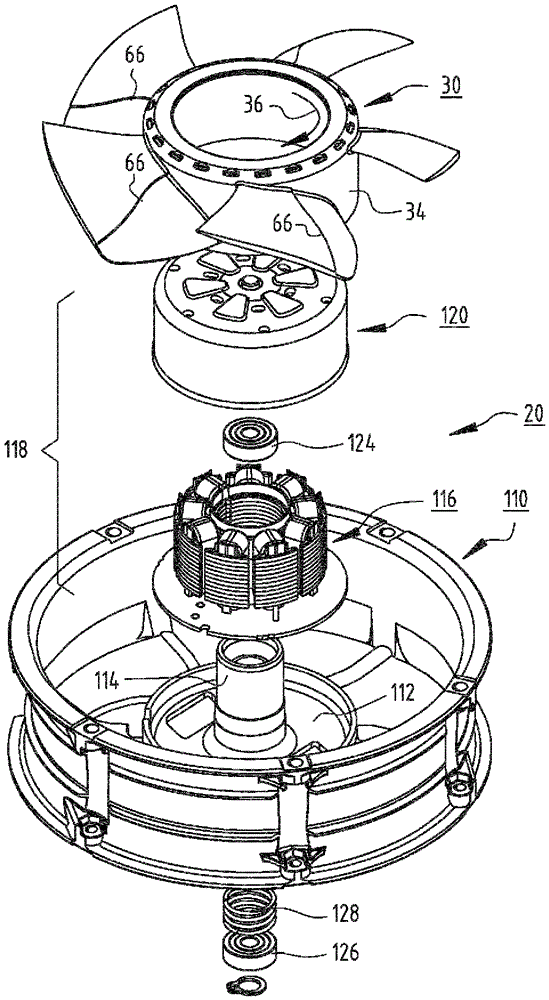

[0019] figure 1 Shown are the main parts of a rotating wheel (ventilator wheel) 30 for an axial fan, for example at Figure 5 is shown in an exploded view.

[0020] In this example, the turning wheel 30 has five turning blades (blades) 32 of a specific profile, which are connected to a hub 34 . The direction of rotation of the rotating wheel 30 is indicated at 36 and in this example moves clockwise when viewing the rotating wheel 30 in the direction of the arrow 38 from above.

[0021] The hub 34 has an opening 40 into which a so-called balancing weight can be inserted during balancing, as soon as an imbalance is determined.

[0022] Since the rotor blades 32 are mostly identical and have the same or similar angular distance from each other, it is sufficient to consider one of the rotor blades 32 in detail, in figure 1 The rotor blade is shown on the lower left in the center. The rotor blades are usually produced together with the hub 34 and the other rotor blades 32 , oft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com