Hydraulic damper with adjustable rebound valve assembly

A hydraulic damper, damper technology, applied in the direction of spring/shock absorber, spring, shock absorber, etc., can solve the problems of deviation, inflection point position uncertainty, low repeatability of opening torque, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

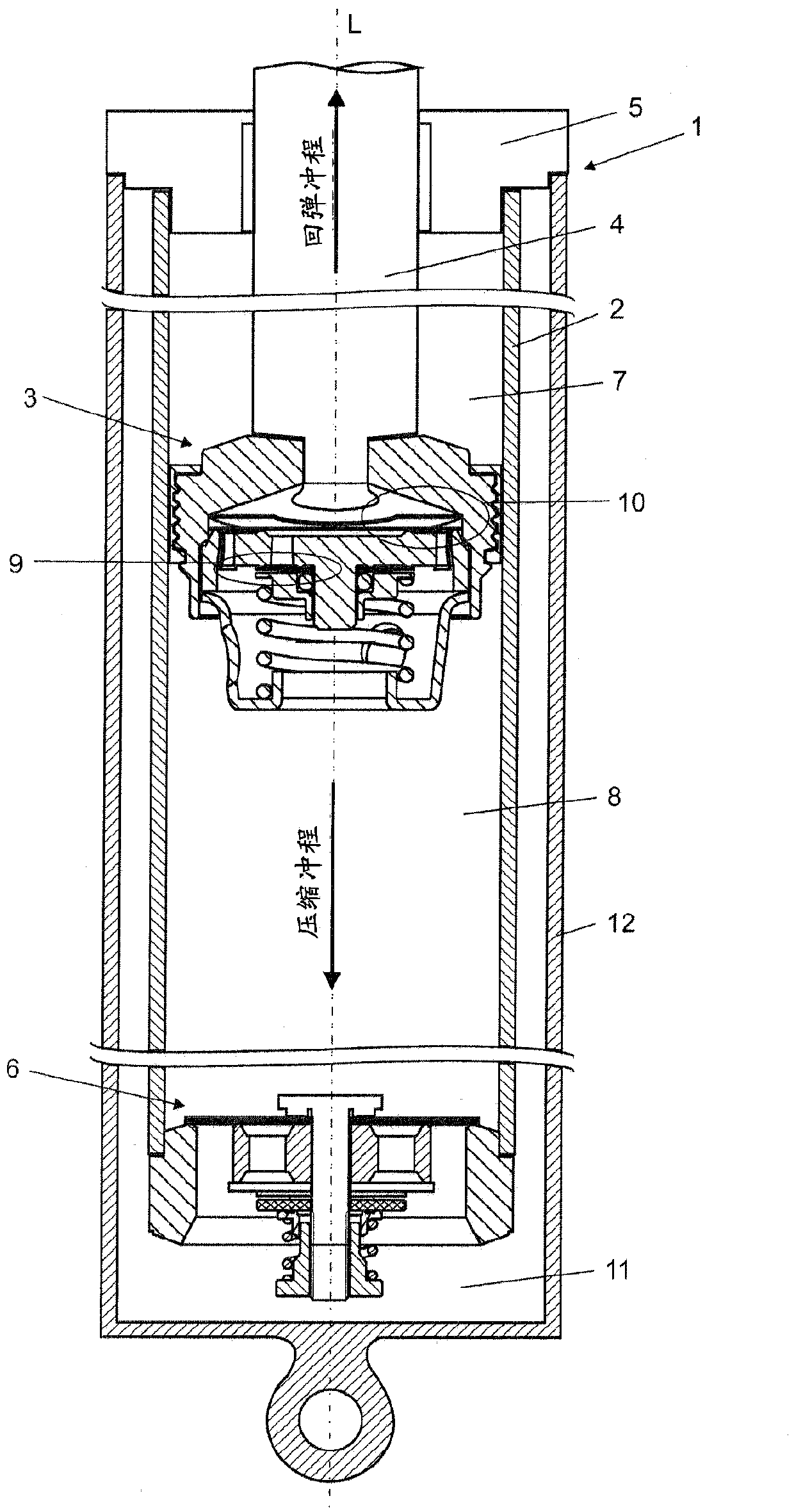

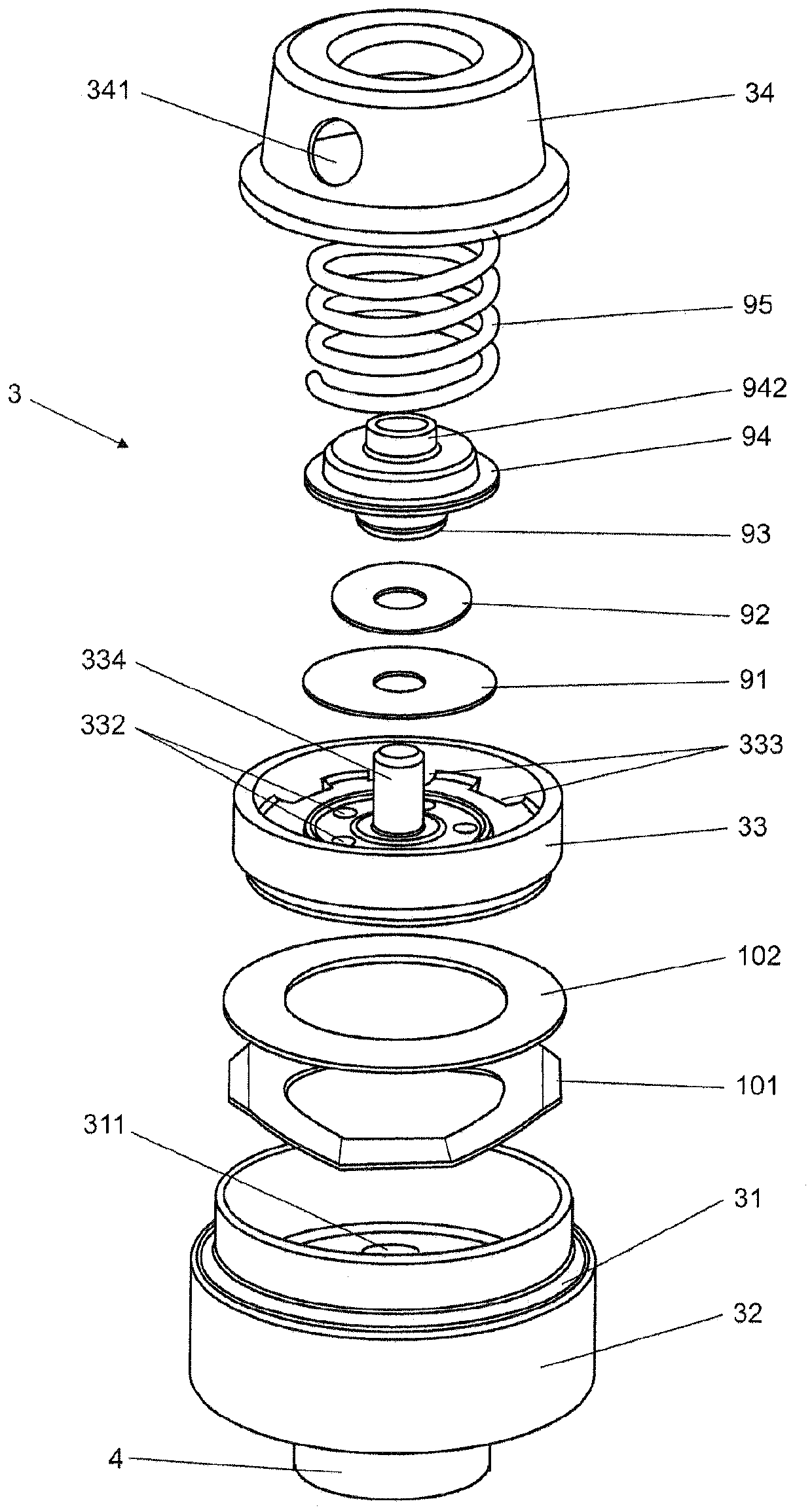

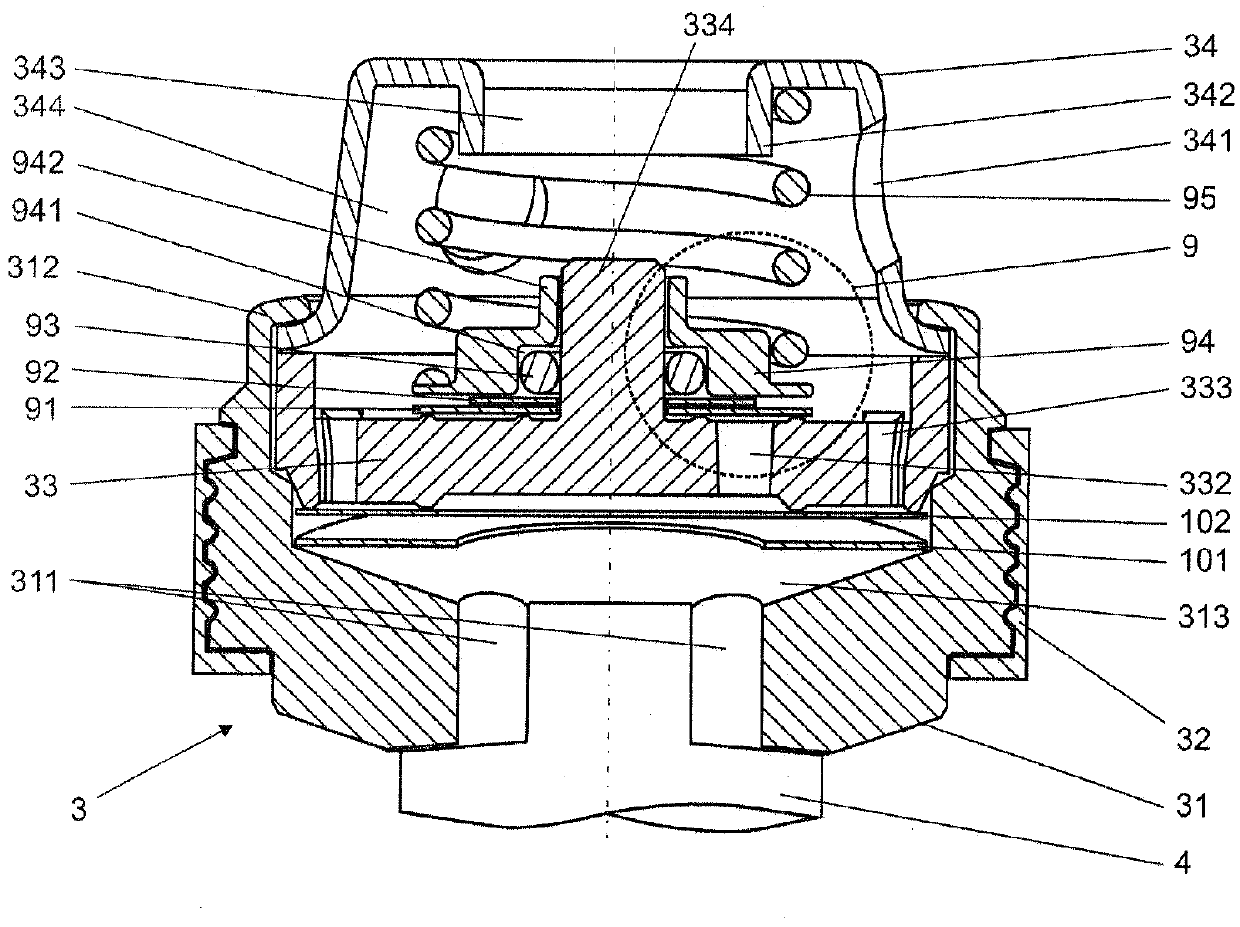

[0019] figure 1 The hydraulic damper 1 shown in is an example of a two-tube damper. Inside the inner tube 2 filled with working fluid, there is a slidable piston assembly 3 . The piston assembly 3 is connected to a piston rod 4 which is guided axially to the outside of the damper 1 via a sealed piston rod guide 5 . At the other end of the tube 2, a base valve assembly 6 is provided. The piston assembly 3 is in sliding fit with the inner surface of the tube 2 and divides the tube 2 into a rebound chamber 7 and a compression chamber 8 . The piston assembly 3 also includes a rebound valve assembly 9 and a compression valve assembly 10 with flow passages to control the flow of working fluid through the piston assembly 3 during the rebound stroke and the compression stroke of the damper 1 . The base valve assembly 6 is also provided with a rebound valve assembly and a compression valve assembly having a flow passage to control the flow of working fluid between the compression ch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com