Method and equipment for directly treating water burst on coal mining work face

A coal mining face, direct technology, applied in the field of direct treatment of coal mining face water gushing, direct purification treatment of coal mining face water gushing, can solve the problems of long construction period, difficult cleaning, small capacity of water tanks in the mining area, etc. , to achieve the effect of reducing cleaning times, ensuring normal water storage, and reducing the difficulty of clearing and digging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

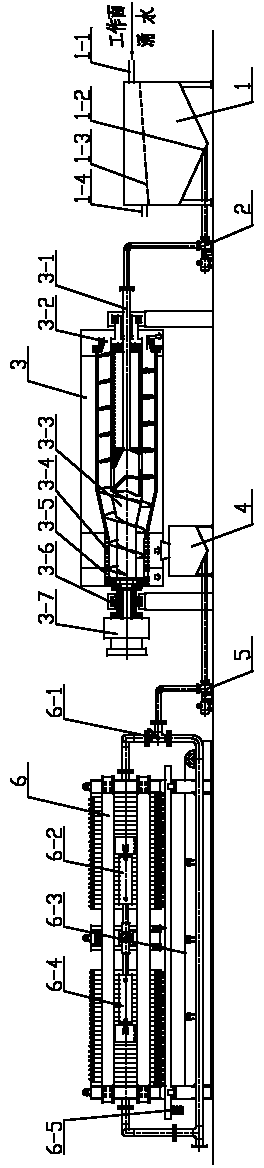

[0011] The steps of the method for directly treating water inrush from a coal mining face of the present invention are as follows:

[0012] Step 1: Send the working surface water gushing directly into the primary buffer tank 1 for primary screening, and discharge large pieces of dry materials. The slime water mixture under the screen is hoarded in the primary buffer tank to adjust the working surface water gushing and the system processing speed is inconsistent. Fluctuations, waiting for pumping;

[0013] Step 2: Start the mud transfer pump 2 to send the slime-water mixture in the primary buffer tank to the horizontal spiral sedimentation filter centrifuge 3;

[0014] Step 3: The slime-water mixture is again settling and separated under the action of centrifugal force. Part of the coarser slime is discharged from the dry slime outlet 3-5 and transported away by the mine truck, and part of the relatively clean water is discharged from the drain 3-2 and Flow into the central sump, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com