Novel press roll position adjusting mechanism

A new type of pressing roller technology, applied in the direction of metal rolling stand, metal rolling mill stand, metal rolling, etc., can solve the problems of affecting the forming effect of sheet metal parts, time-consuming and laborious relative distance, inaccurate adjustment distance, etc. The up and down adjustment is convenient and firm, easy to control, and the molding effect is good.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with specific embodiments.

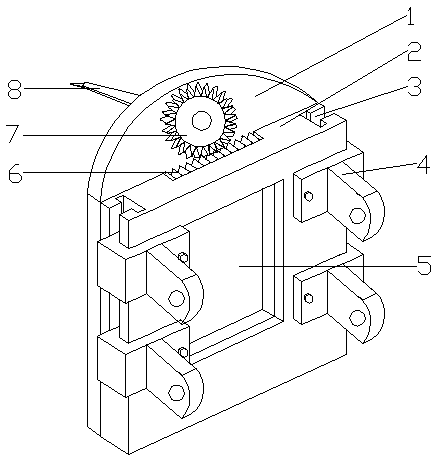

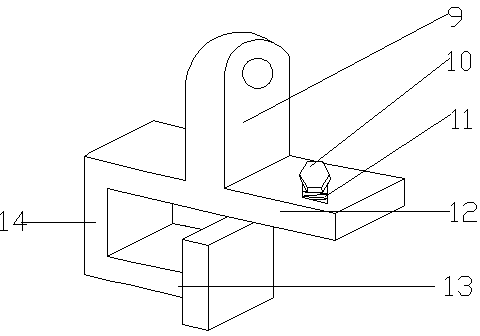

[0020] like figure 1 and figure 2 As shown, a novel pressure roller position adjustable mechanism includes a pressure roller fixing plate 2 and a backing plate 1. The pressure roller fixing plate 2 is provided with a rectangular feeding port 5, a pressure roller mounting seat 4 and a track groove 3. The rectangular feed opening 5 is located in the middle of the pressure roller fixing plate 2; the track groove 3 has two, which are respectively vertically arranged on both sides of the pressure roller fixing plate 2, and the track groove 3 has a section along the vertical direction. A "T"-shaped groove; the pressure roller mount 4 includes a pressure roller bracket 9, a base 12 and a guide block, the base 12 is a rectangular structure, and the pressure roller bracket 9 is vertically fixed on the rectangular base 12 The middle part; the guide block 13 has a "T" shape struct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com