Feeder driving mechanism of full-automatic screw locking machine

A technology for locking screw machines and driving mechanisms, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve problems such as damage to workpiece screw holes, screw damage, and inability to ensure the accuracy of screws, and achieve the effect of preventing scrapping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

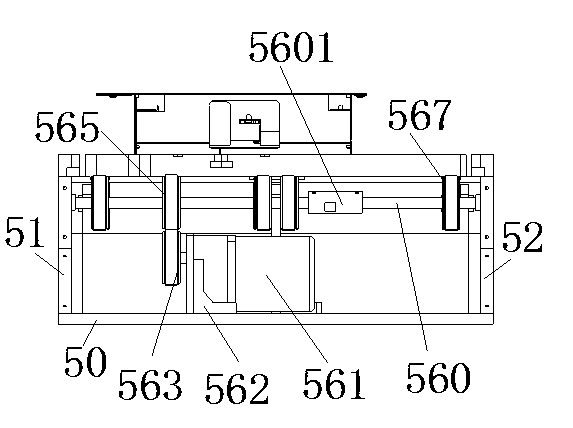

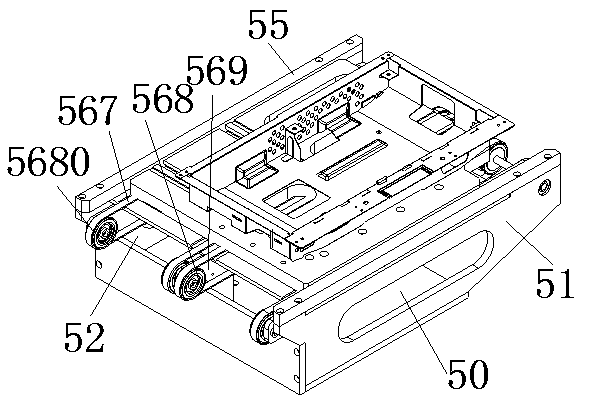

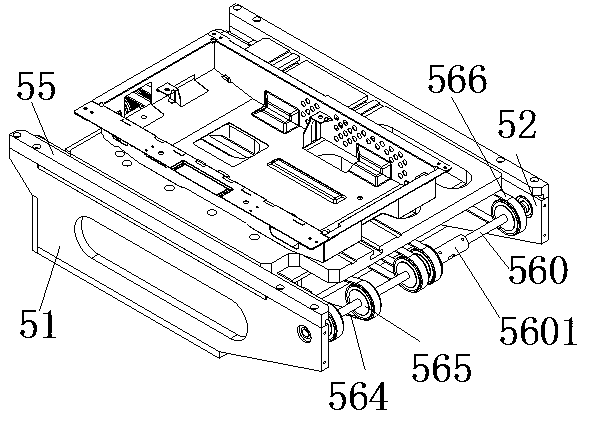

[0012] see Figure 1 to Figure 3 , the embodiment of the present invention includes:

[0013] A feeder drive mechanism of a fully automatic screw locking machine, the feeder drive mechanism of the fully automatic screw lock machine includes a feed drive shaft 560, a feeder drive motor 561, a feeder motor mounting frame 562, a feeder Device motor driving pulley 563, feeder motor belt 564, feeder motor driven pulley 565, feeder feeding belt 566, feeder feeding driving pulley 567, feeder feeding driven pulley 568 and feeder feeding Driven belt pulley seat 569, the feeder drive motor 561 of described belt speed reducer is installed on the feeder motor mount...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap