Constant-center-height grinding method of tapered roller centerless grinding machine

A centerless grinding machine and tapered roller technology, which is applied in the direction of grinding machines, grinding/polishing equipment, and machine tools designed for grinding the rotating surface of workpieces, etc. It can solve problems such as low work efficiency, cumbersome operation, and difficult adjustment of parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0078] The present invention will be further described below in conjunction with the examples, but not as a limitation to the present invention. The scope of protection of the present invention is based on the contents of the claims. Any equivalent technical means replacement made according to the description will not depart from the scope of the present invention. protected range.

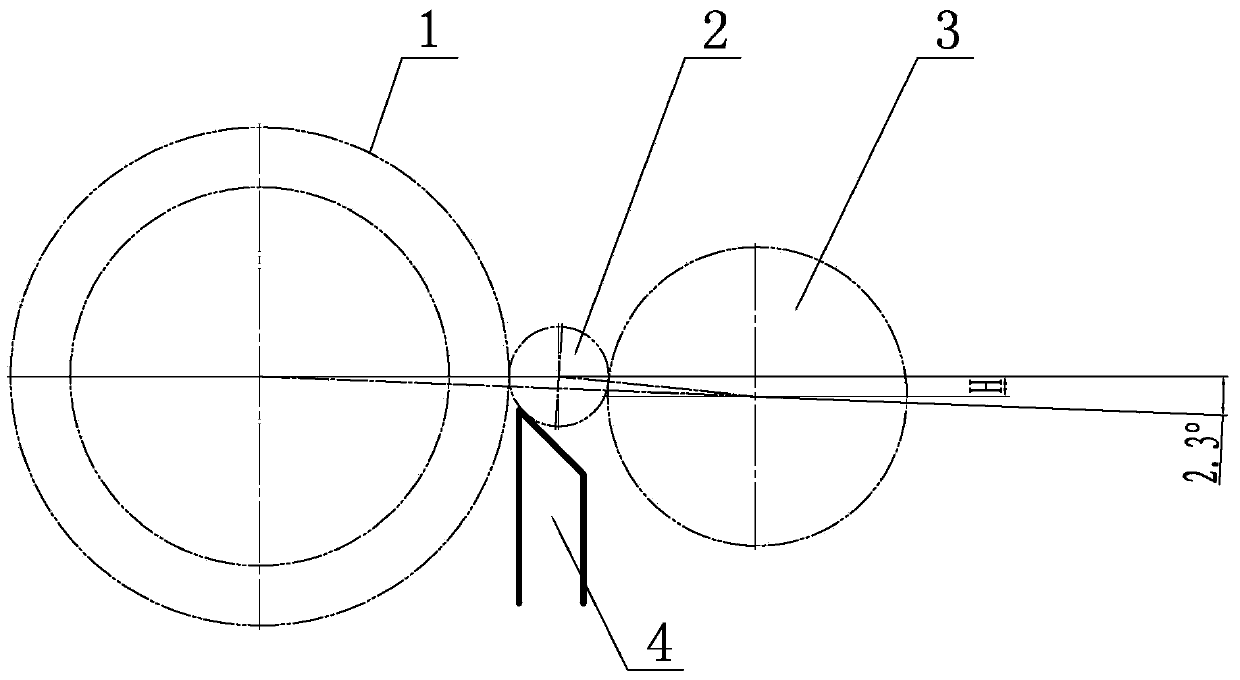

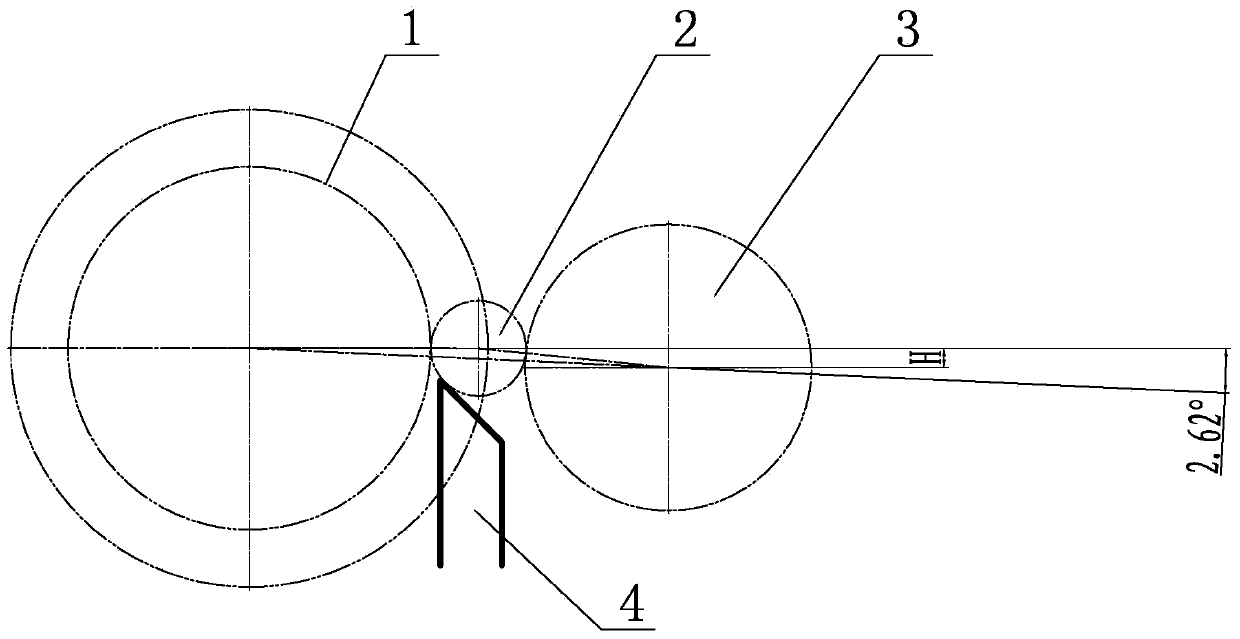

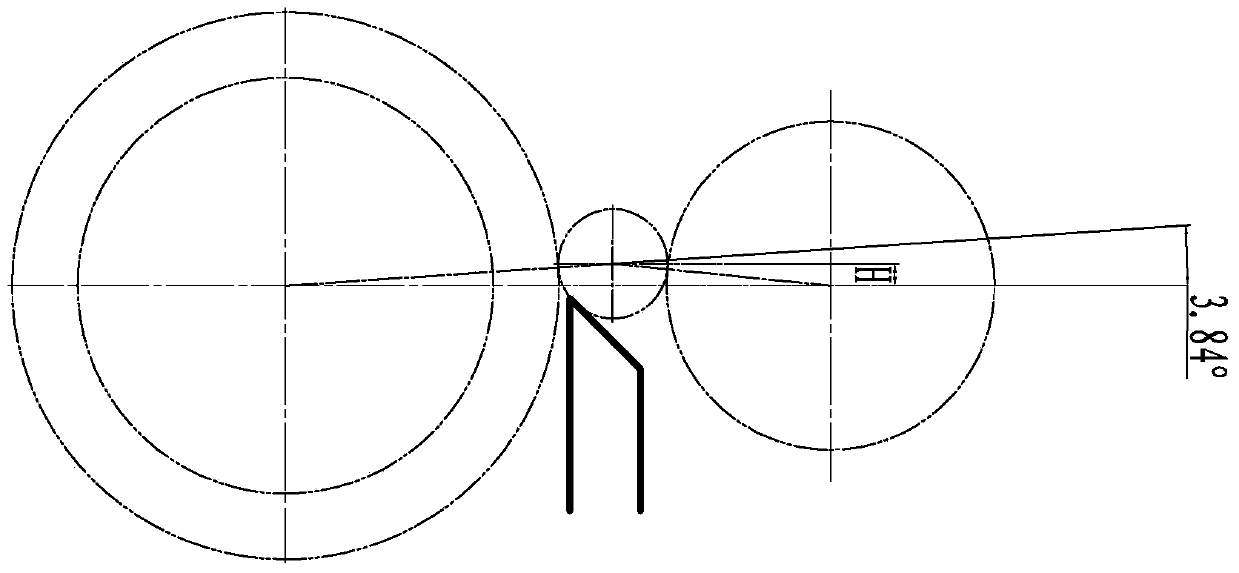

[0079] The overall structure of this embodiment is shown in the figure. The constant center height grinding method of the tapered roller centerless grinder is to drive the roller 2 to be processed between the grinding wheel 1, the guide wheel 3 and the guide plate 4 to rotate by the guide wheel 3, and The roller 2 to be processed is ground by the grinding wheel 1; during the grinding process, the center of the roller 2 to be processed and the center of the grinding wheel 1 are located on the same horizontal line.

[0080] During the processing, the center position (center height) of the roller doe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com