Automobile glass sound insulation film drawing technology

A technology of automotive glass and sound insulation film, applied in glass/slag layered products, other household appliances, flat products, etc., can solve the problems of luminous distortion, air bubbles, poor edge sealing, etc., achieve low air humidity, increase cold drawing time , the effect of reducing moisture content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention comprises the steps:

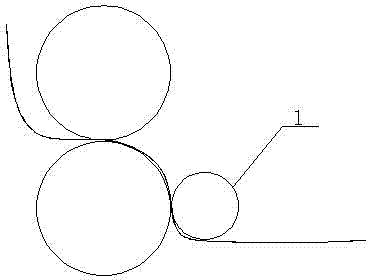

[0035] a. Flattening: add a pressing rod 1 at the front end of the upper film roller of the film stretching machine (such as figure 1 As shown), the sound-insulating diaphragm is flattened by the pressure bar 1 before the upper film roller, and enters the film stretching machine smoothly under the tension of the upper film roller to eliminate the creases of the sound-insulating diaphragm;

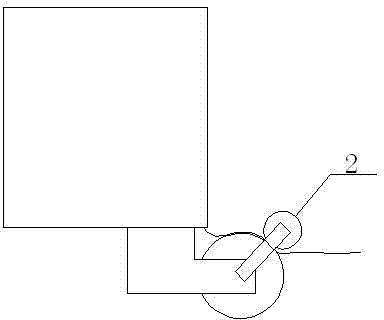

[0036] b. Evening: Add a B pressure rod 2 at the exit of the ice machine (such as figure 2 Shown), under the force of the pressure rod 2, the sound insulation diaphragm is evened out. Let the sound insulation film pass through the stretching roller smoothly;

[0037] c. Humidity adjustment: The sound insulation membranes processed by the ice machine enter the temperature and humidity adjustment room for the humidity adjustment process. The humidity adjustment process is carried out on pallets. The stacking requirements for each pallet o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com