Volume recovery method of non-woven fabric

A volume recovery, non-woven technology, applied in textiles and papermaking, heating/cooling fabrics, fabric surface trimming, etc. Volume more reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0156] In order to confirm the effect of the present invention, an experiment was conducted to compare the state of volume restoration between the volume restoration method of the present invention and a conventional volume restoration method not based on the present invention.

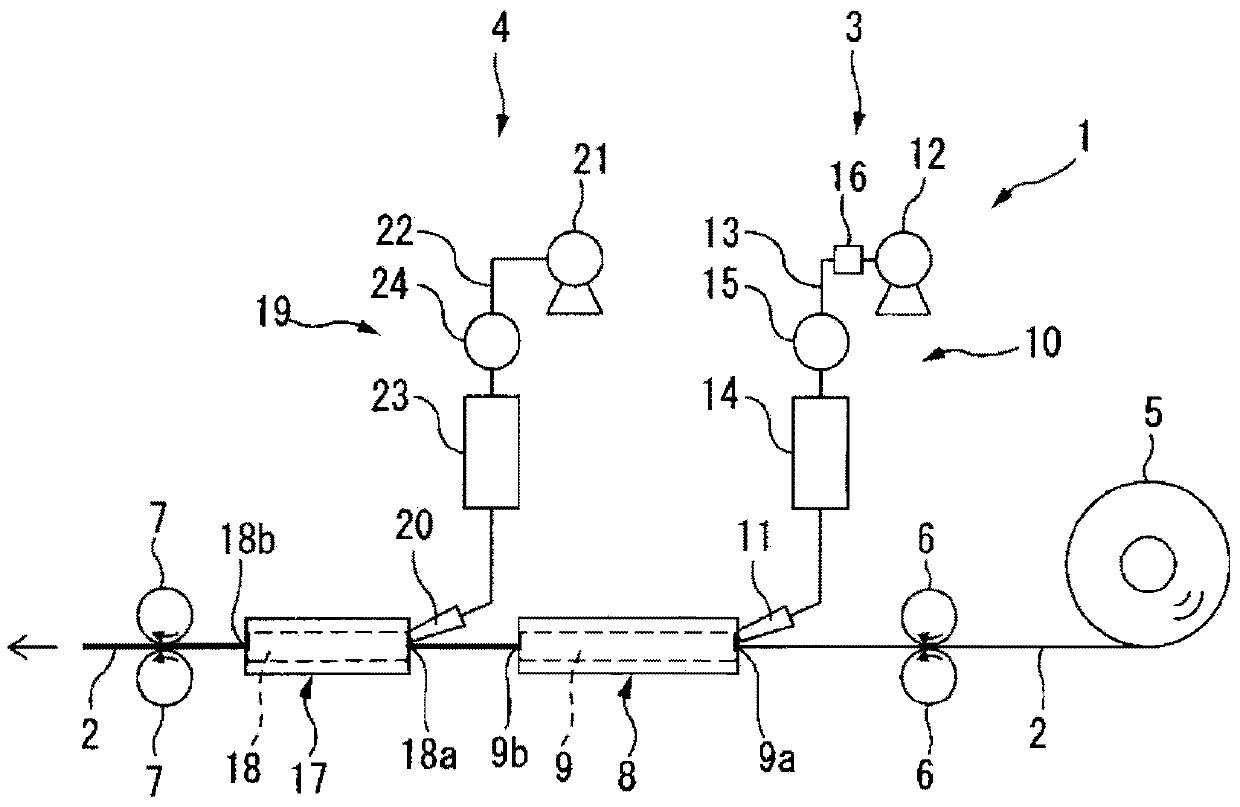

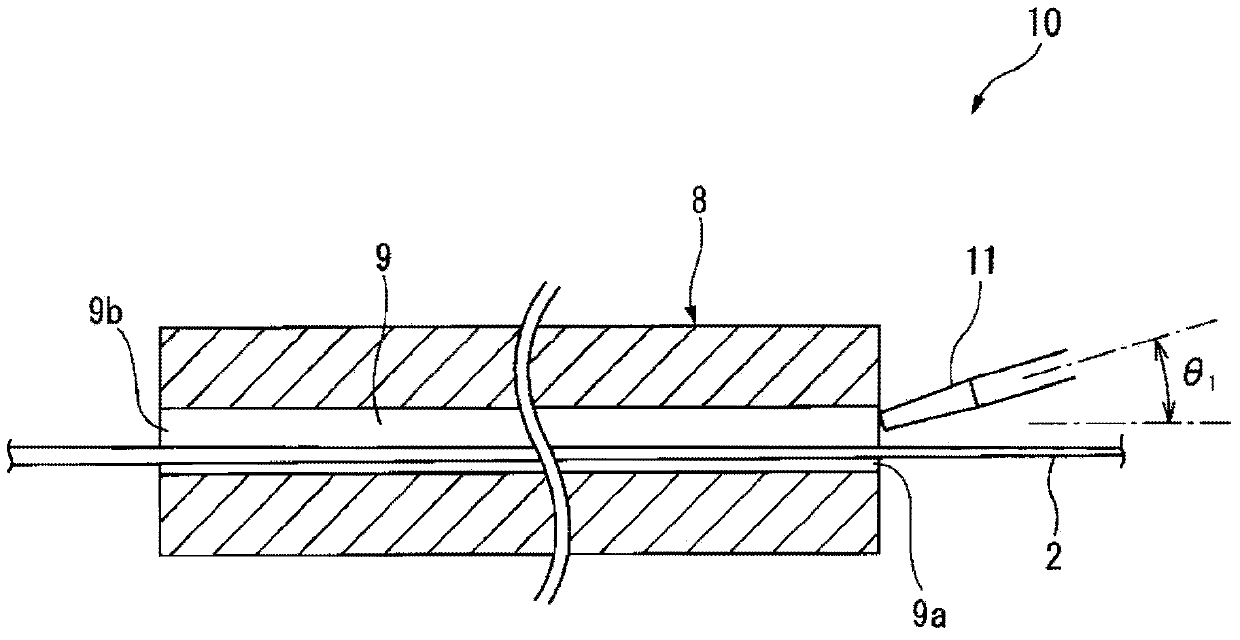

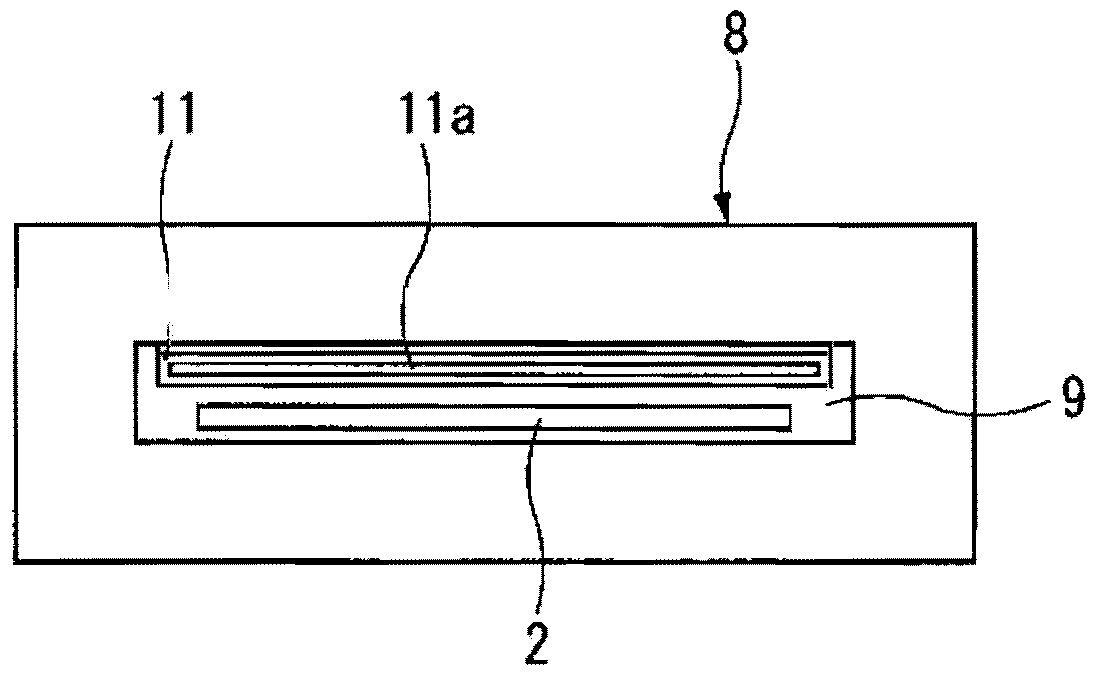

[0157] Specifically, in this example, the volume restoration method of the present invention was implemented using the volume restoration apparatus described in the second embodiment above, and as a conventional volume restoration method, the volume restoration method described in the above-mentioned Patent Document 1 was implemented. Such a volume restoration method performed by a hot air type device that blows hot air substantially perpendicularly to the surface of the nonwoven fabric being conveyed.

[0158] Then, by comparing a sample (hereinafter referred to as an example) whose volume was restored by the volume restoration method of the present invention with a sample (hereinafter referred to as ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com