Booster Hydraulics

A hydraulic device and hydraulic technology, applied in the direction of fluid pressure actuators, fluid pressure converters, servo motor components, etc., to achieve the effect of control, compact structure, and smooth switching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

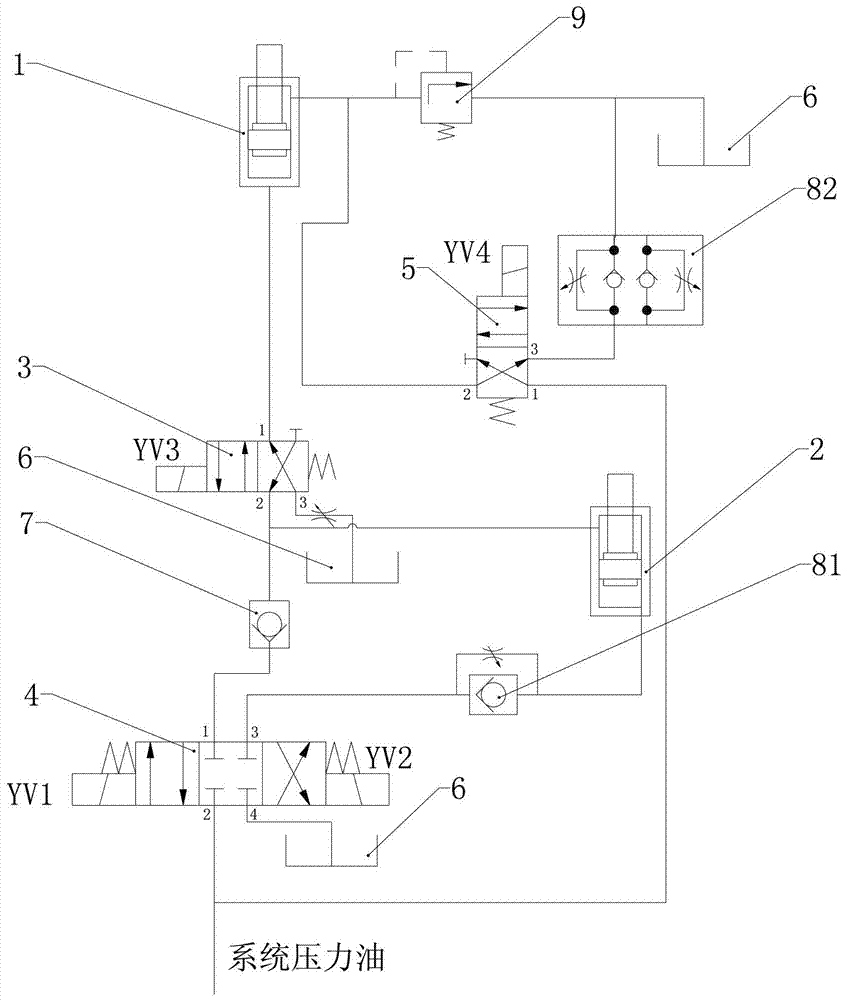

[0018] like figure 1 As shown, the pressurized hydraulic device of the present invention is mainly composed of a power cylinder 1, a pressurized cylinder 2, a first electromagnetic reversing valve 3, a second electromagnetic reversing valve 4, a third electromagnetic reversing valve 5, an oil return Pool 6, one-way valve 7, first one-way throttle valve 81, second one-way throttle valve 82 and safety valve 9.

[0019] The power cylinder 1 is the ejection cylinder of the cooking utensil forming press, and is arranged on the base of the press. The rod cavity of the power cylinder is connected with the oil return tank 6, and the safety valve 9 is connected in series on the connecting pipeline.

[0020] The first electromagnetic reversing valve 3 is a two-position four-way electromagnetic reversing valve, its first oil port is connected to the rodless chamber of the power cylinder 1, and its second oil port is connected to the rod chamber of the booster cylinder 2 ; Its third oil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com