Lamp installation part

A technology for mounting parts and lamps, which is applied to the parts of lighting devices, lighting devices, fixed lighting devices, etc., can solve the problems of inconvenient maintenance and installation of lamps, inability to prevent loosening, poor tightness, etc., to improve the efficiency of disassembly and maintenance, The effect of simplifying the screw connection structure and easy injection molding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

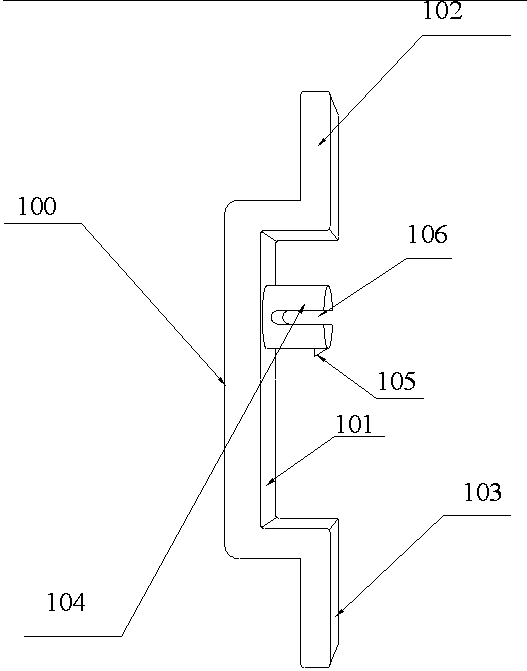

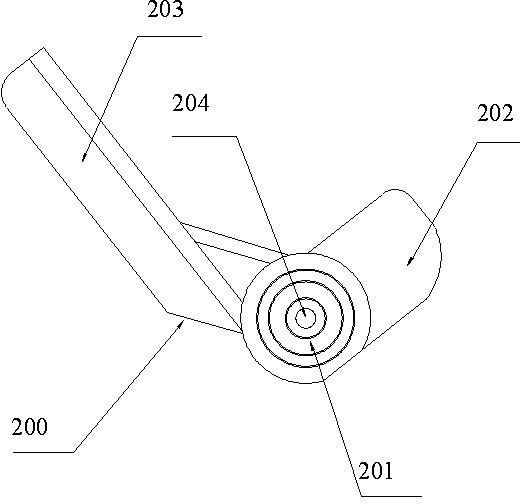

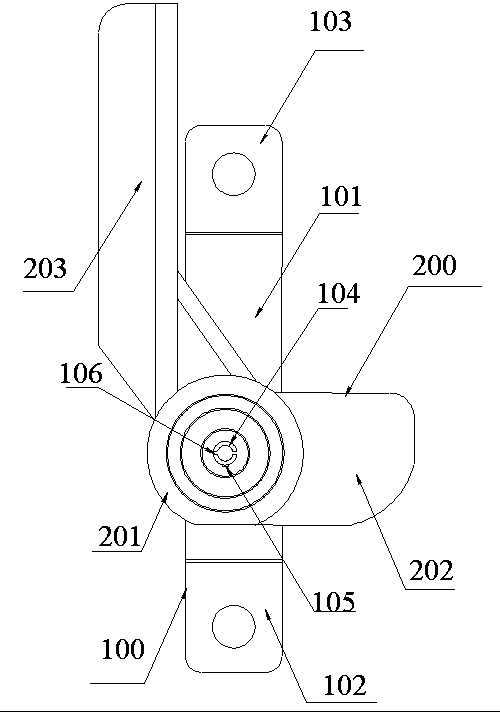

[0019] refer to Figure 1 to Figure 5 , proposes an embodiment of a lighting fitting of the present invention, which can be used for the installation and connection between the ceiling lamp chassis and the frame structure, including a fixed structure 100 and a rotating structure 200 snap-connected with the fixed structure 100 . The fixed structure 100 includes a top plate 101, a first fixed foot 102 and a second fixed foot 103 extending downwards from both ends of the top plate 101, and the first fixed foot 102 and the second fixed foot 103 are both provided with mounting holes. The L-shaped structure facing outwards, the lower end of the top plate 101 is provided with a cylindrical protruding piece 104, and the middle of the protruding piece 104 is provided with an elastic channel 106 that can make the protruding pie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com