Impact device

A technology of impact device and impact mechanism, applied in impact drilling, portable impact tool, driving device for drilling in wellbore, etc., can solve the problem of reducing the throttling effect of guide parts, reducing the bearing capacity of oil film and damaging the efficiency of hydraulic hammer and other problems, to achieve the effect of improving the load-bearing capacity and increasing the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

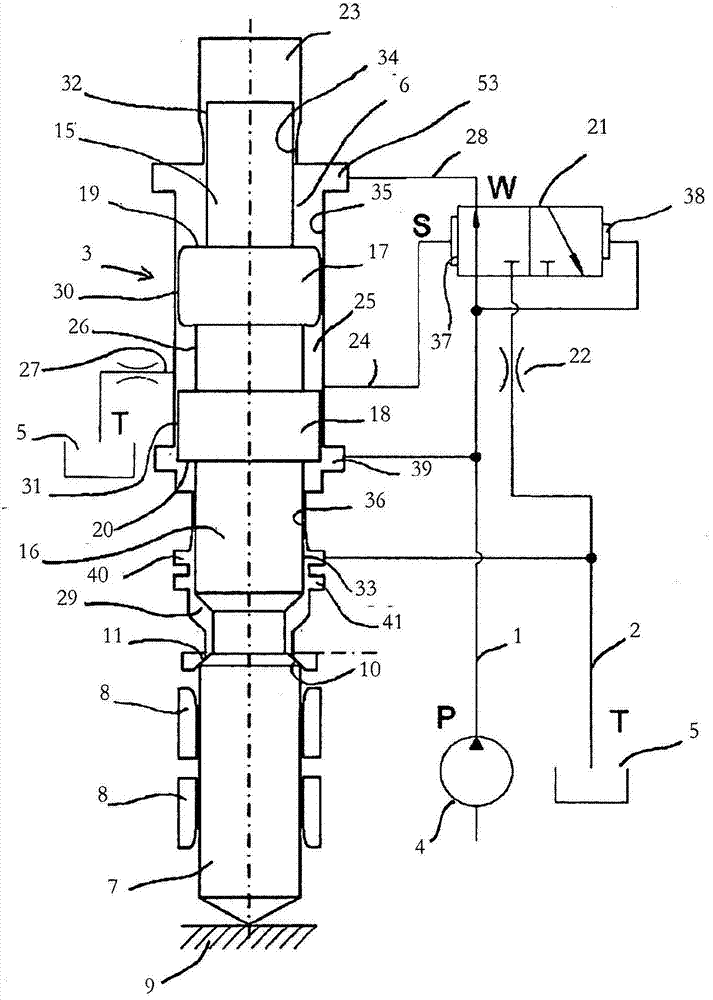

[0049] figure 1 and figure 2 The mode of operation of the hydraulic percussion device is shown diagrammatically in . The impact mechanism 3 is hydraulically connected to a pump 4 and a tank 5 of a supporting device (eg an excavator) via a pressure line 1 and a tank line 2, respectively. On the excavator there is a valve to which the line 1 to the pump can be connected in order to supply the impact mechanism with pressurized oil for operation, or this connection can be disconnected in order to stop the operation of the impact mechanism. For greater clarity, this valve is not shown.

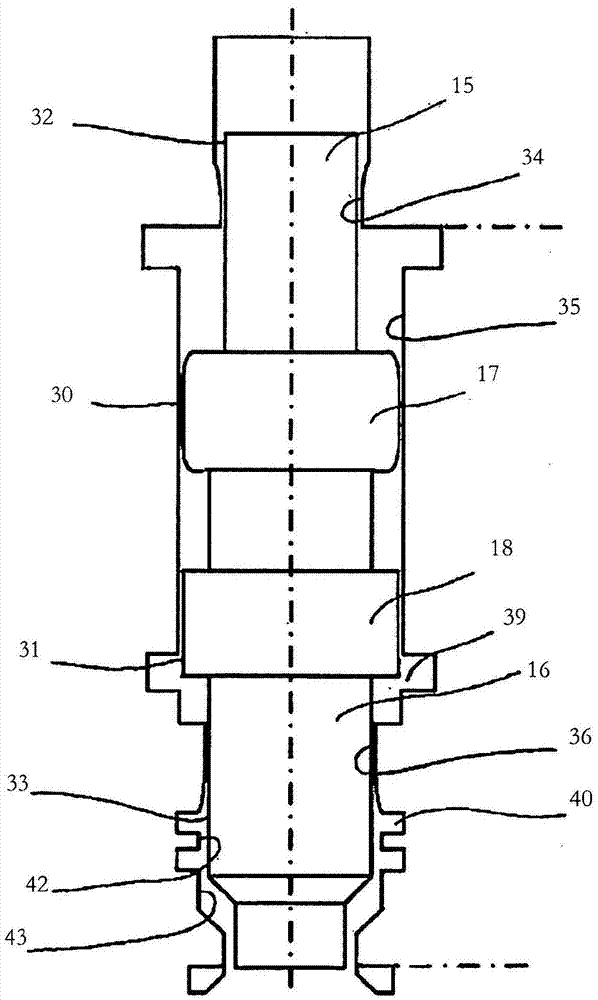

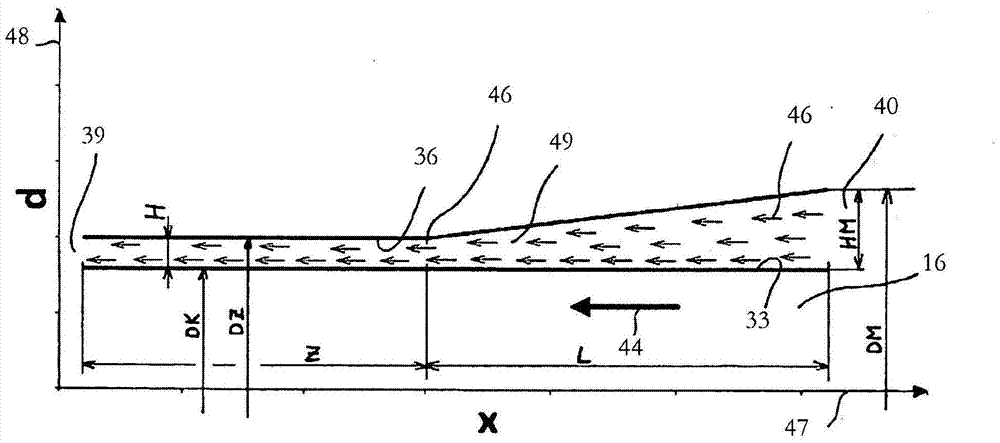

[0050]The striking mechanism 3 is formed by a striking mechanism housing, in which a striking piston 6 is guided. The striking mechanism housing can consist of several parts connected by screws, such as a cylinder head, a cylinder and a chisel seat in which the chisel 7 is mounted by means of a bearing bush 8 . Only the simplified inner contour of the receiving opening of the striking mechani...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com