Aperture-adjustable reamer

A reamer and hole diameter adjustment technology, used in drilling/drilling equipment, maintenance and safety accessories, drilling tool accessories, etc., can solve the problems of complicated operation, increase the cost of drilling or reaming tools, etc., and achieve simple operation. , the effect of reducing tool cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

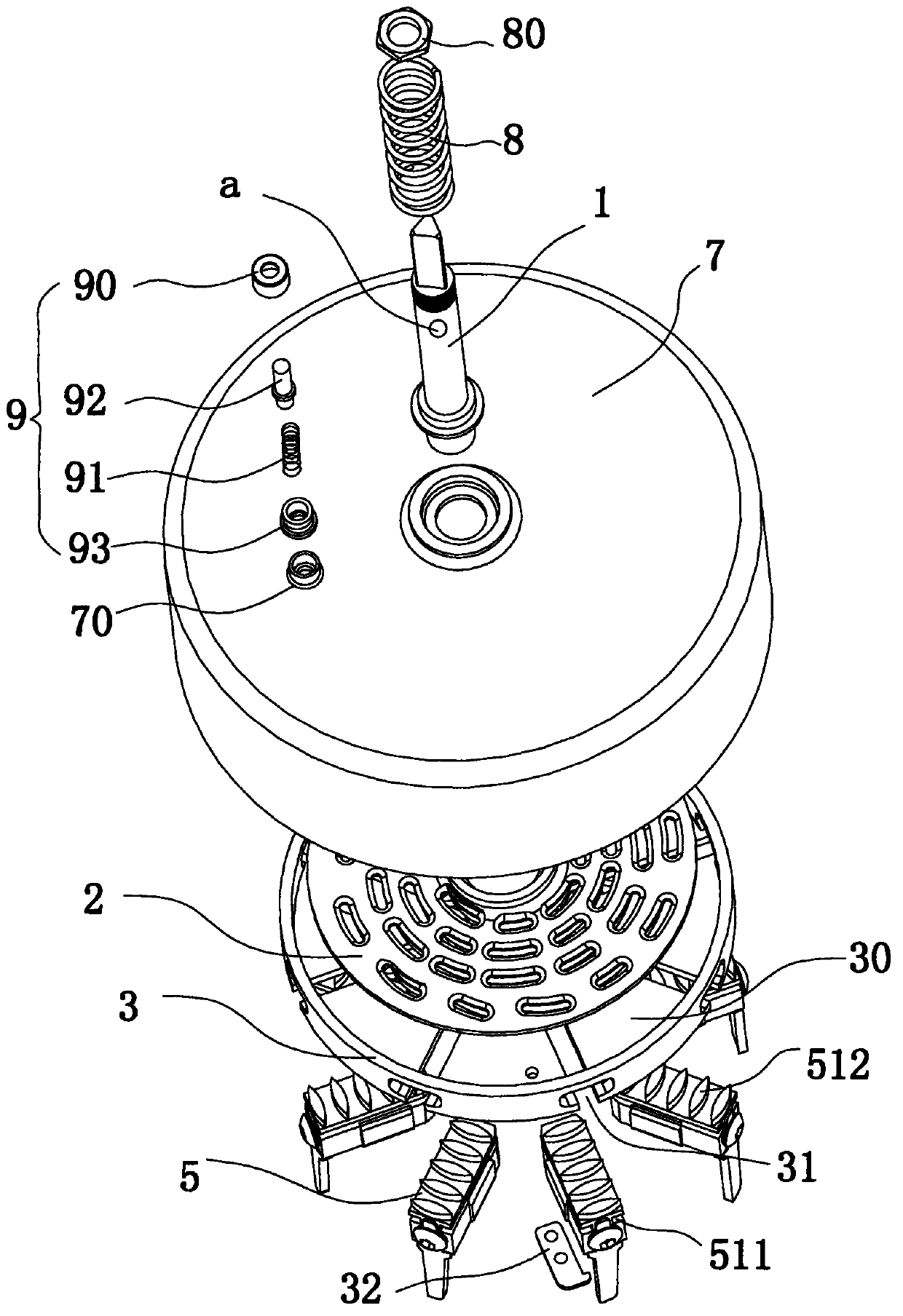

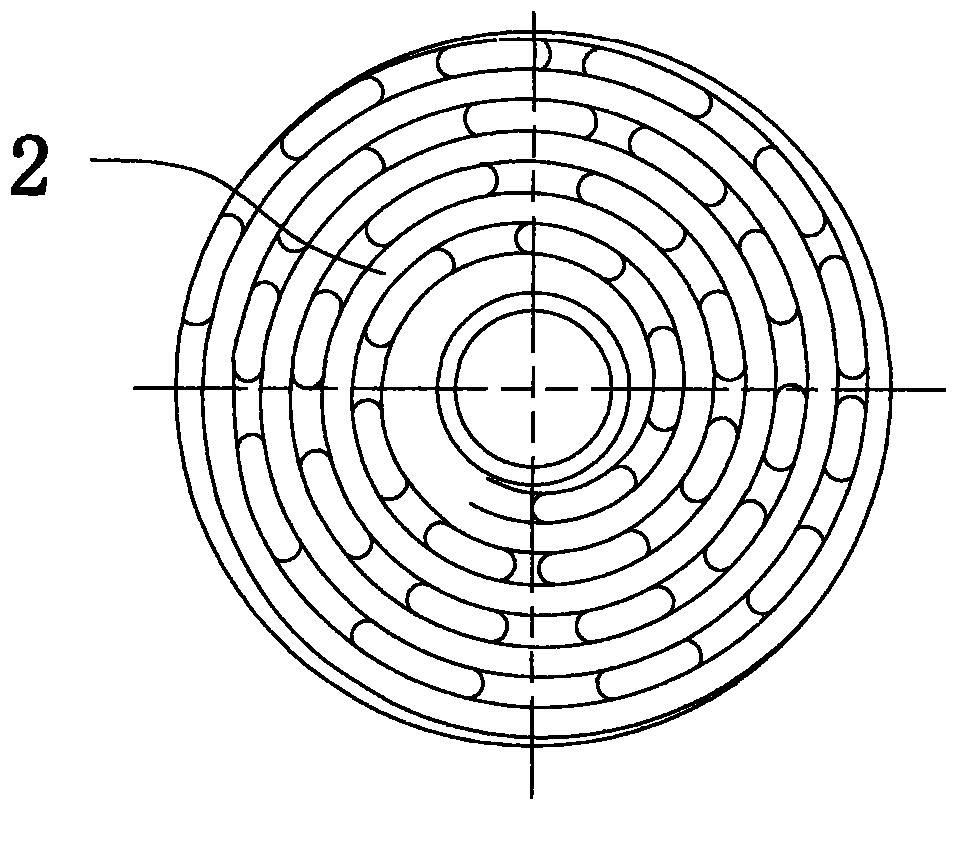

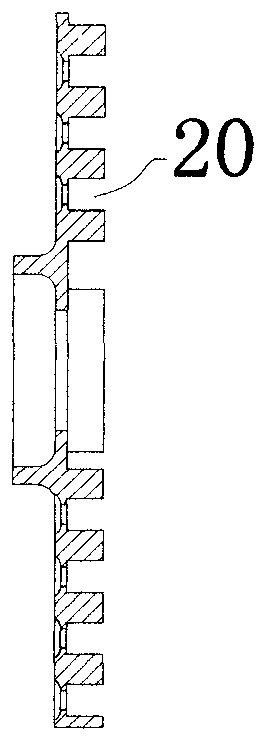

[0028] Adjustable bore reamers such as Figure 1 to Figure 11 As shown, it includes a main shaft 1 connected to the output shaft of the motor; one end of the main shaft 1 is connected with a circular aperture adjustment disc 2, and the aperture adjustment disc 2 is rotatably fitted in the cutter head 3 provided at its front end. The rear side is provided with a fitting groove 30 nested with the aperture adjustment disc 2; in the radial direction of the front side of the cutter head, there are 4 pairs of blade assemblies 5 arranged symmetrically with respect to the center of the cutter head 3, and the blade assemblies 5 include blades 50 , a knife seat 51 and a knife seat locking assembly 52, the blade 50 is vertically fixed on the knife seat 51, and blade fixing grooves 510 are respectively provided on the front and rear sides of the knife seat 51, and the blade 50 is fixed to the knife seat by screws 500 51 in the blade fixing groove 510 on the front side or the rear side to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com