Electric hammer with shock absorber

A shock-absorbing device, electric hammer technology, applied in the direction of striking tools, manufacturing tools, lightweight impact tools, etc., can solve the problems of reducing the overall structural strength, misalignment of the hammer rod hitting point, easy distortion and deformation, etc., to reduce the degree of distortion and deformation , The effect of simplifying the overall structure and strengthening the structural strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in detail below with reference to the drawings and embodiments.

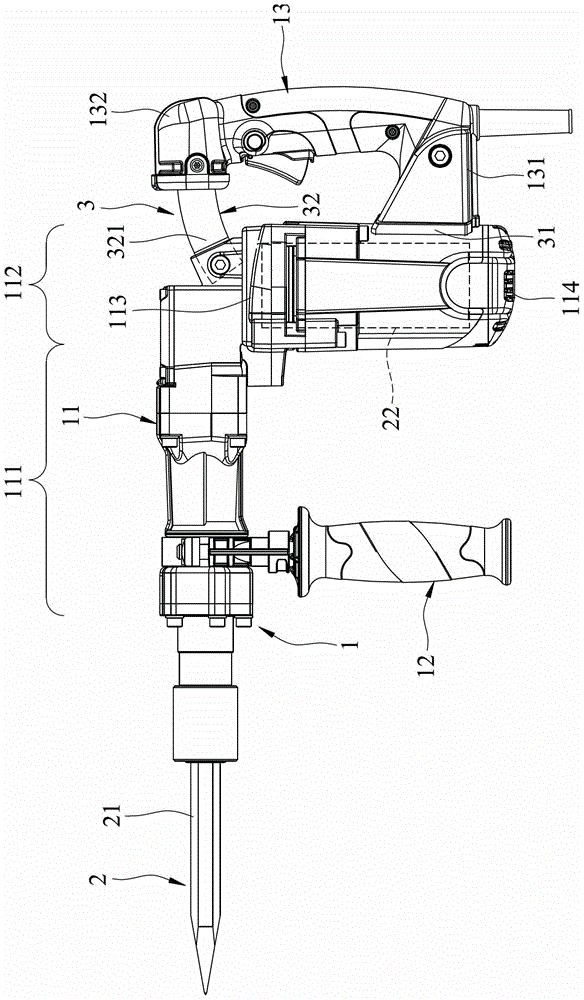

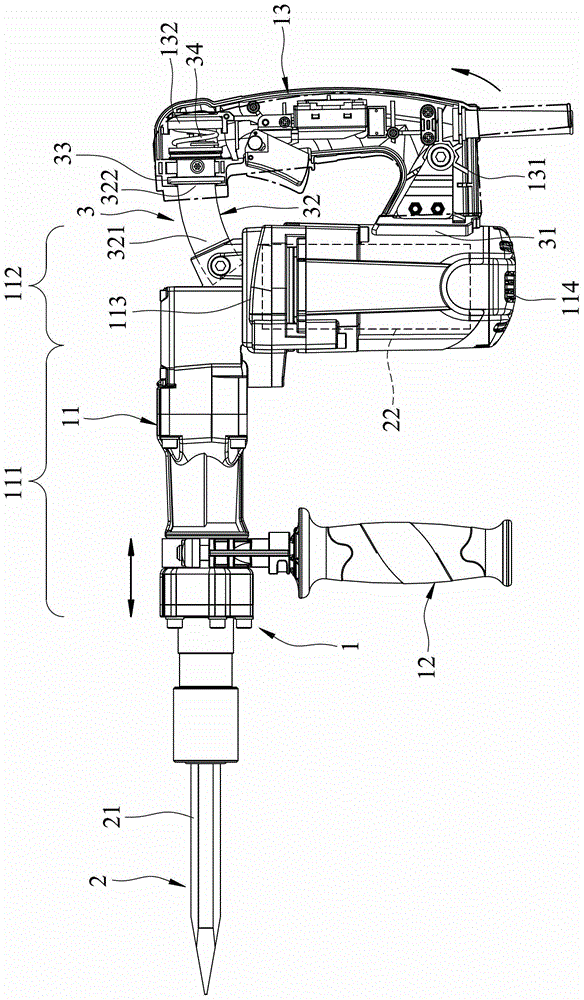

[0020] Refer to figure 1 versus figure 2 , The preferred embodiment of the electric hammer with shock absorption device of the present invention includes a housing unit 1, an electric hammer unit 2 and a shock absorption device 3.

[0021] The housing unit 1 includes a housing 11, an auxiliary grip 12 and a driving grip 13.

[0022] The housing 11 is approximately L-shaped and has a front end 111 and a rear end 112 opposite to each other. The rear end 112 has an upper side 113 and a lower side 114 connected to the front end 111 in opposite directions.

[0023] The auxiliary grip 12 is fixed below the front end 111 and parallel to the rear end 112.

[0024] The driving handle 13 has a pivotal end 131 pivoted at the rear end 112, and a free end 132 that is opposite to the pivotal end 131 and can swing with the pivotal end 131 as a fulcrum. . In this embodiment, the pivotal ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com