Full automatic box cutting machine

A fully automatic, box-cutting technology, which is applied in packaging, transportation and packaging, and unsealing of objects, etc., can solve the problems of large manpower, material resources, financial resources, increased production costs of breweries, and reduced economic benefits of enterprises, so as to reduce labor costs , Improve on-site sanitation and reduce management and maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

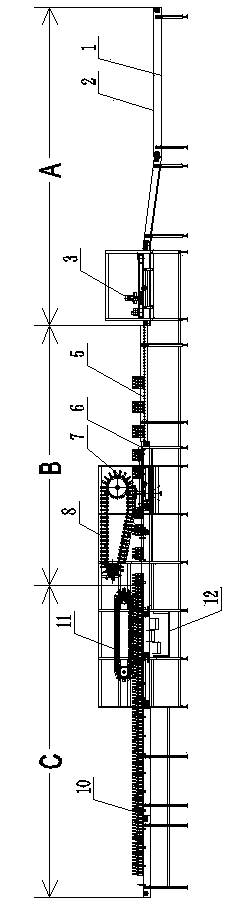

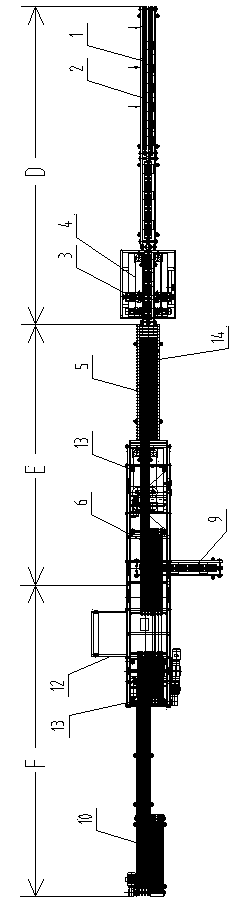

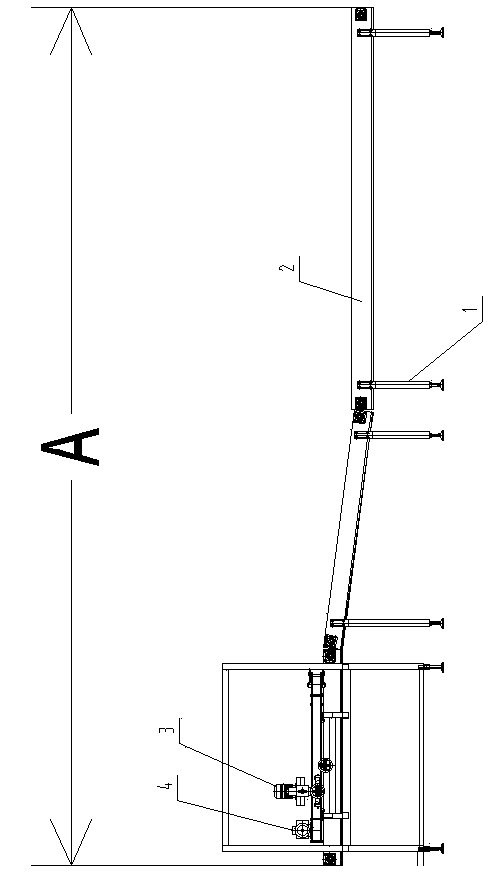

[0045] like figure 1As shown in -8, the present invention mainly includes a frame 1, which is connected with a box delivery device 2, a first box cutting device 3 is arranged at the front end of the box delivery device 2, and a box delivery device 2 is arranged on the front side of the box delivery device 2. Turning to the conveying device 5, an intermediate conveying device 6 is set on the front side of the steering conveying device 5, a second cutting box device 7 is set above the intermediate conveying device 6, and a box cover separating device 8 is set above the second cutting box device 7, On the left side of the case cover separation device 8, a case cover conveying device 9 is set, and a bottle conveying device 10 is arranged on the front side of the intermediate conveying device 6, and a gap 17 is set between the bottle conveying device 10 and the intermediate conveying device 6. The top of the front end of the device 6 and the rear end of the bottle output conveying ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com