polyacetal resin composition

A technology of polyacetal resin and composition, applied in the field of polyacetal resin composition, can solve the problems of poor working environment, damage to the surface of molded products, and reduced dimensional accuracy of molded products, etc., and achieves excellent weather resistance, adhesion prevention, The effect of high creep characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~7

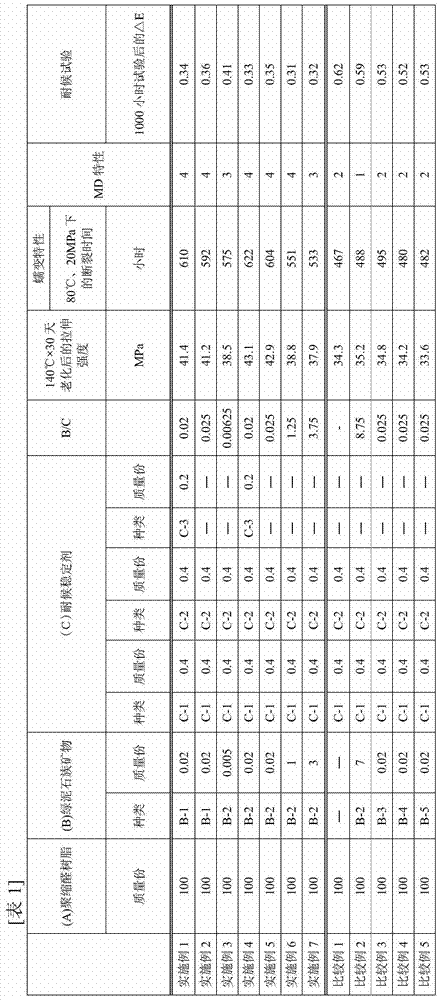

[0123] 100 parts by mass of (A) polyacetal resin (melting point: 164.5° C.) produced above and 0.15 parts by mass of calcium stearate as a formic acid scavenger were uniformly mixed using a Henschel mixer to obtain a mixture. The mixture was fed from the main inlet of a twin-screw extruder with a 30mm vent port at L / D=30 set at 200°C, and (B) chlorite in the amount shown in Table 1 The group minerals and (C) weathering stabilizer were fed from the side feed port located downstream of the main feed port, and melted and kneaded at a screw speed of 100 rpm to obtain a polyacetal resin composition. The mechanical properties, high-temperature creep properties, MD properties, and weather resistance of the obtained polyacetal resin composition after heat aging were evaluated by the methods described above. The results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap