Method for electrolyzing ferric oxide by using deep eutectic solvent to prepare ferroferric oxide

A technology of triiron tetroxide and low eutectic solvent, applied in the electrolysis process, electrolysis components and other directions, can solve the problems of long process flow, complicated operation, strict equipment requirements, etc., and meet the requirements of simple preparation process, wide source and equipment low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

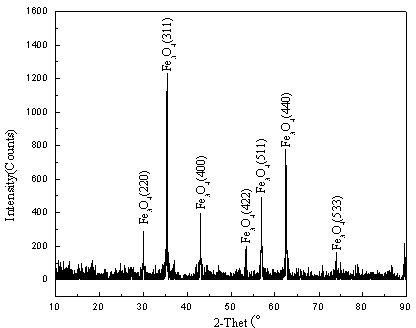

Image

Examples

Embodiment 1

[0018] The method for preparing ferric oxide by electrolyzing ferric oxide with a deep eutectic solvent, the specific steps are as follows:

[0019] (1) Preparation of cathode sheet: mix ferric oxide, PVA binder and pore-forming agent, press to form, and then bake at 800°C for 3 hours to obtain cathode sheet, wherein the pore-forming agent is ammonium bicarbonate, three The addition amount of ferric oxide, PVA binder and pore forming agent are 0.60g, 0.10g, 0.14g respectively;

[0020] (2) Configure a deep eutectic solvent: mix choline chloride and ethylene glycol at a molar ratio of 1:1, heat and stir at 80°C to form a deep eutectic solvent;

[0021] (3) With graphite as the anode, the cathode sheet prepared in step (1) is used as the cathode, and DC electrolysis is performed in the deep eutectic solvent prepared in step (2). During this process, the cell voltage is controlled to 2.5V and the electrolyte temperature is Electrolyze for 20 hours at 80°C, the distance between t...

Embodiment 2

[0025] The method for preparing ferric oxide by electrolyzing ferric oxide with a deep eutectic solvent, the specific steps are as follows:

[0026] (1) Preparation of cathode sheet: mix ferric oxide, PVA binder and pore-forming agent, press to form, and then bake at 800°C for 3 hours to obtain cathode sheet, wherein the pore-forming agent is polyvinyl alcohol, three The addition amount of ferric oxide, PVA binder and pore forming agent are 0.65g, 0.11g, 0.15g respectively;

[0027] (2) Configure a deep eutectic solvent: mix choline chloride and ethylene glycol at a molar ratio of 1:2, heat and stir at 60°C to form a deep eutectic solvent;

[0028] (3) With graphite as the anode, the cathode sheet prepared in step (1) is used as the cathode, and direct current electrolysis is performed in the deep eutectic solvent prepared in step (2). During this process, the cell voltage is controlled to 2.8V and the electrolyte temperature is Electrolyze for 24 hours at 50°C, the distance ...

Embodiment 3

[0031] The method for preparing ferric oxide by electrolyzing ferric oxide with a deep eutectic solvent, the specific steps are as follows:

[0032] (1) Preparation of cathode sheet: mix ferric oxide, PVA binder and pore-forming agent, press to form, and then bake at 800°C for 3 hours to obtain cathode sheet, wherein the pore-forming agent is polyethylene glycol, The addition amount of ferric oxide, PVA binder and pore forming agent is 0.80g, 0.15g, 0.32g respectively;

[0033] (2) Configure a deep eutectic solvent: mix choline chloride and ethylene glycol at a molar ratio of 1:3, heat and stir at 70°C to form a deep eutectic solvent;

[0034] (3) With graphite as the anode, the cathode sheet prepared in step (1) is used as the cathode, and DC electrolysis is performed in the deep eutectic solvent prepared in step (2). During this process, the cell voltage is controlled to 2.0V and the electrolyte temperature is Electrolyze for 14 hours at 60°C and the distance between the ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com