A method of growing rebco blocks upside down

A technology of RE2O3 and growth furnace, which is applied in the field of inverted growth of REBCO blocks, can solve the problems of spontaneous nucleation and component deviation, and achieve the effects of preventing pollution, reducing stress and being easy to prepare

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

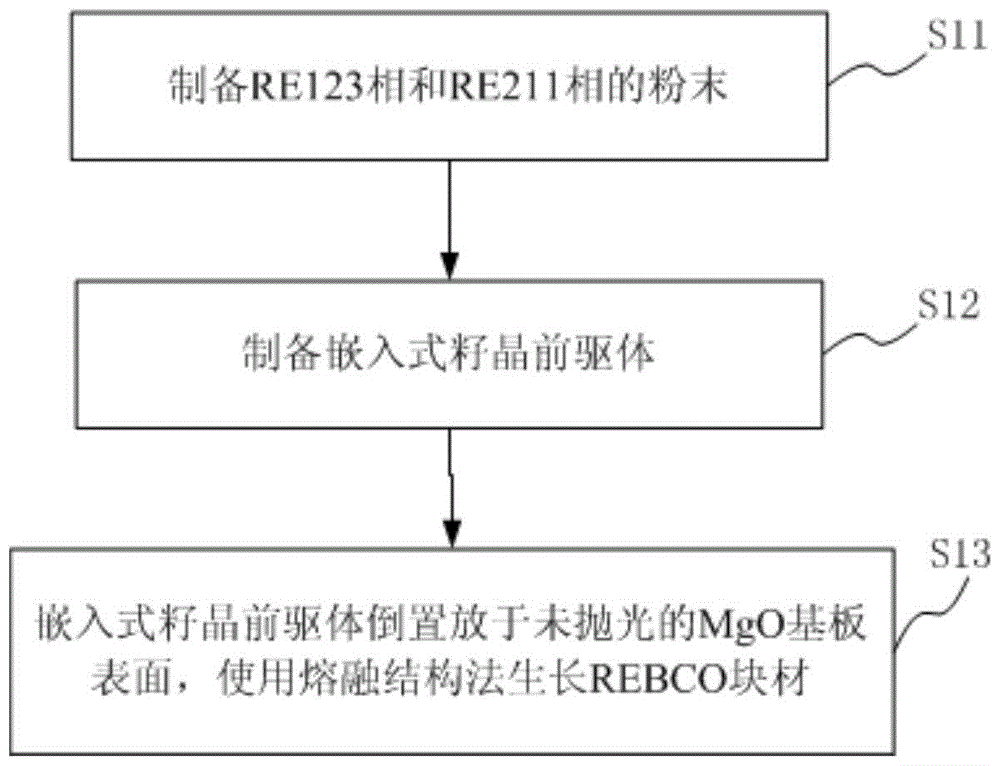

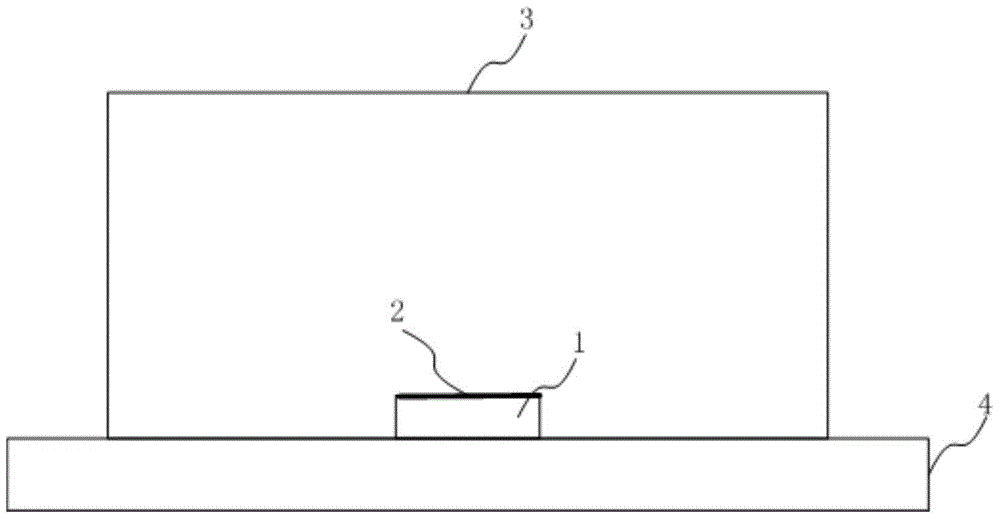

[0047] In this embodiment, a method for growing REBCO bulk materials upside down, wherein REBCO is YBCO, includes the following steps:

[0048] 1. Respectively according to the molar ratio of Y:Ba:Cu=1:2:3 and 2:1:1, the Y 2 O 3 , BaCO 3 Mix with CuO powder to obtain the precursor powders of Y123 and Y211 phases. Then, the precursor powders of Y123 phase and Y211 phase are fully ground and sintered in air at 900°C for 48 hours. The sintered powders are ground again. Sintering at 900°C for 48 hours in air was repeated three times to obtain Y123 and Y211 pure phase powders with uniform composition.

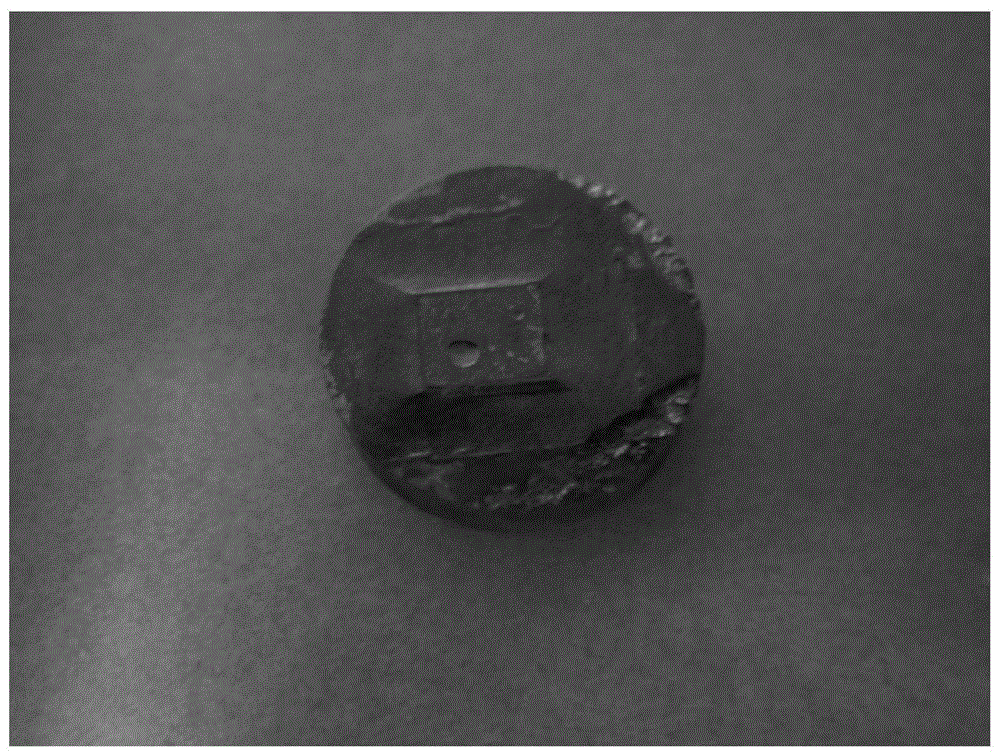

[0049] 2. Mix the pure phase powders of Y123 and Y211 in a molar ratio of 1:30%, and then mix the mixed powder with CeO 2 The powder is mixed according to the components of 1:1% by mass, and after fully grinding and mixing, take 10g of the mixed powder for use; select the seed material of the c-axis oriented NdBCO / YBCO / MgO film with a size of 2mm×2mm, and the film The induced growth surf...

Embodiment 2

[0060] A method for growing YBCO bulk material upside down, including the following steps:

[0061] 1. According to the molar ratios of Y:Ba:Cu=1:2:3 and 2:1:1, the Y 2 O 3 , BaCO 3 Mix with CuO powder to obtain the precursor powders of Y123 and Y211 phases, and then fully grind the precursor powders of Y123 phase and Y211 phase and sinter them in the air at 900°C for 48 hours. The sintered powders are ground again, Sintering at 900°C for 48 hours in air was repeated three times to obtain Y123 and Y211 pure phase powders with uniform composition.

[0062] 2. Mix the pure phase powders of Y123 and Y211 according to the molar ratio of 1:30%, and then mix the mixed powder with CeO 2 The powder is mixed according to the components of 1:1% by mass, and after fully milling and mixing, take 10g of the mixed powder for use; select the seed crystal material of the c-axis oriented NdBCO / YBCO / MgO film with a size of 2mm×2mm. The induced growth surface of the seed crystal (the side with the Nd...

Embodiment 3

[0070] A method for growing YBCO bulk material upside down, including the following steps:

[0071] 1. Respectively according to the molar ratio of Y:Ba:Cu=1:2:3 and 2:1:1, the Y 2 O 3 , BaCO 3 Mix with CuO powder to obtain the precursor powders of Y123 and Y211 phases, and then fully grind the precursor powders of Y123 phase and Y211 phase and sinter them in the air at 900°C for 48 hours. The sintered powders are ground again, Sintering at 900°C for 48 hours in air was repeated three times to obtain Y123 and Y211 pure phase powders with uniform and single components.

[0072] 2. Mix the pure phase powders of Y123 and Y211 according to the molar ratio of 1:30%, and then mix the mixed powder with CeO 2 The powder is mixed according to the components of 1:1% by mass, and after fully milling and mixing, take 10g of the mixed powder for use; select the seed crystal material of the c-axis oriented NdBCO / YBCO / MgO film with a size of 2mm×2mm. The induced growth surface of the seed crystal...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap