Water condenser, washing-drying machine and clothes drying method

A water condenser and condenser technology, applied in the field of washing and drying clothes, can solve the problems that the heat exchange plate is easily washed down by the water flow, the installation is cumbersome, and the structure is complicated, so as to improve the condensation efficiency, heat exchange efficiency, and drying efficiency. The effect of dry performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

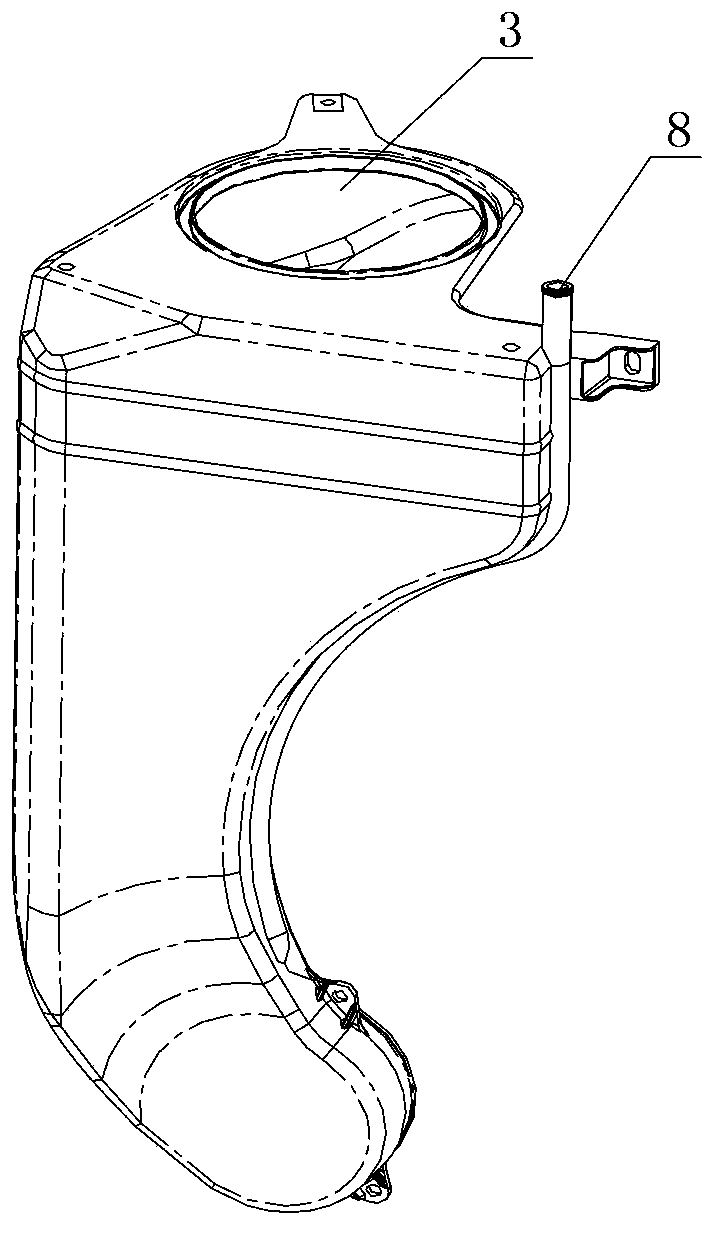

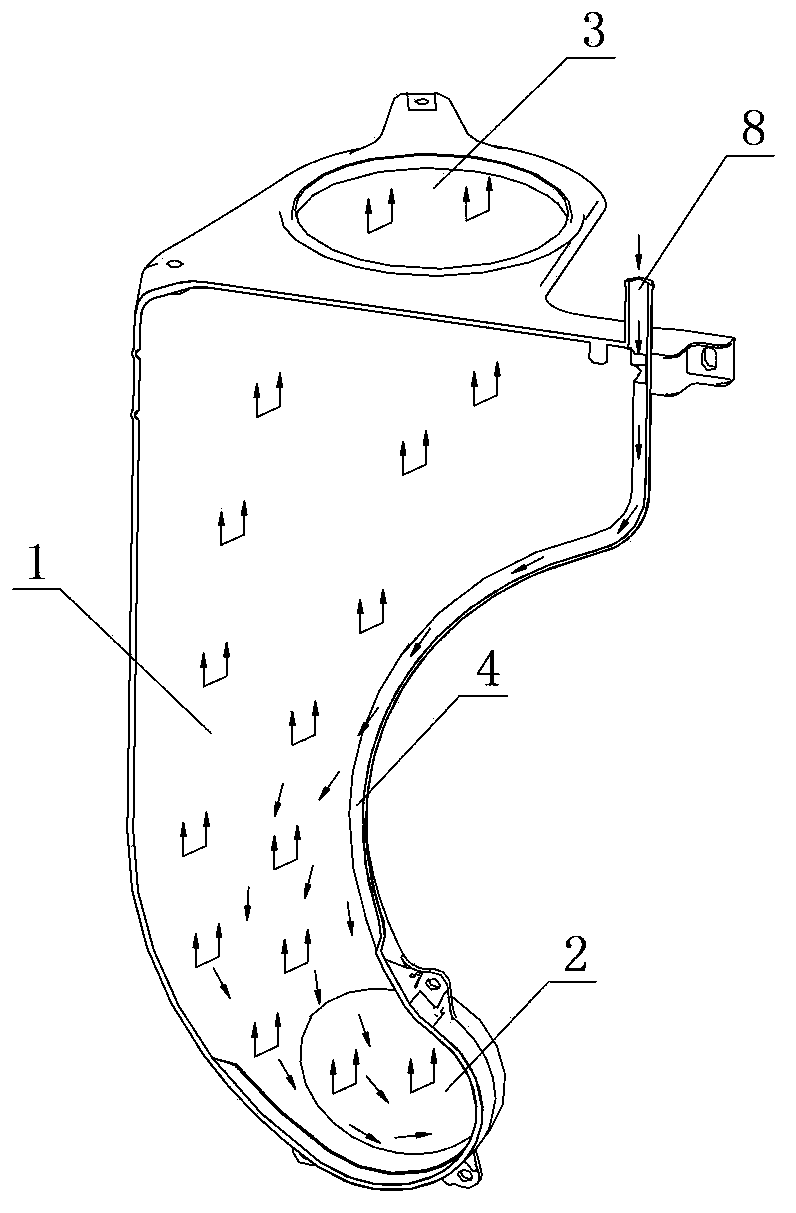

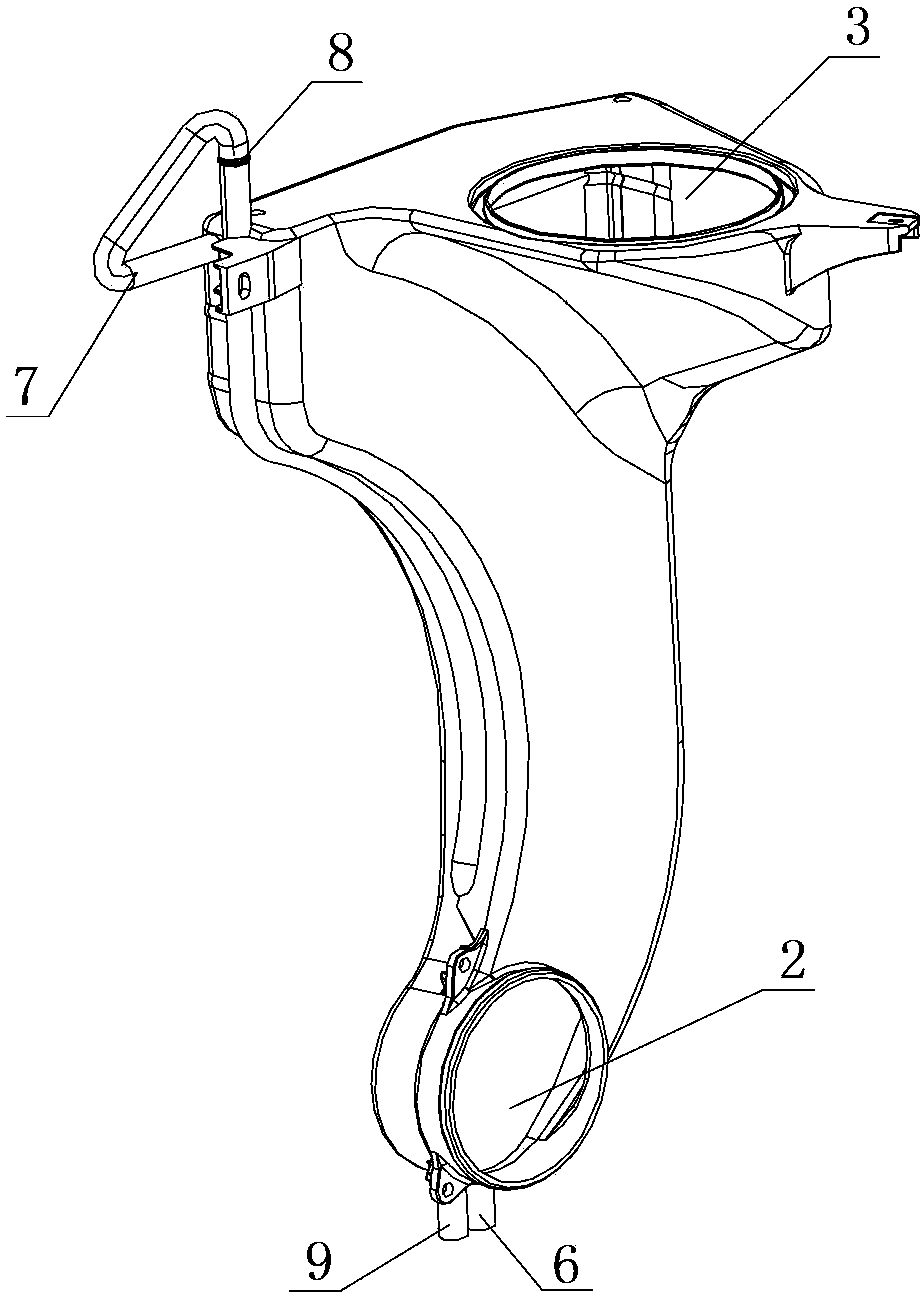

[0043] Such as image 3 , Figure 4 , Figure 5 As shown, the water condenser in this embodiment includes a condenser chamber 1, a hot and humid air inlet 2 located at the lower part of the condenser chamber 1, a dry air outlet 3 located at the upper part of the condenser chamber 1, and a The direct heat exchange condensate flow channel 4 on the inner wall and the indirect heat exchange condensate water interlayer 5 located on the outer wall of the condenser chamber 1, the condensate water in the condensate water flow channel 4 directly contacts the hot and humid air in the condenser chamber 1 for heat exchange , the condensed water in the condensed water interlayer 5 exchanges heat indirectly with the hot and humid air through the chamber wall of the condenser.

[0044] The lower part of the condensed water interlayer 5 is provided with the first condensed water inlet 6, the upper part of the condensed water interlayer 5 is provided with the first condensed water outlet 7, ...

Embodiment 2

[0048] Such as Figure 6 As shown, the water condenser in this embodiment includes a condenser chamber 1, a hot and humid air inlet 2 located at the lower part of the condenser chamber 1, a dry air outlet 3 located at the upper part of the condenser chamber 1, and a The direct heat exchange condensate flow channel 4 on the inner wall and the indirect heat exchange condensate water interlayer 5 located on the outer wall of the condenser chamber 1, the condensate water in the condensate water flow channel 4 directly contacts the hot and humid air in the condenser chamber 1 for heat exchange , the condensed water in the condensed water interlayer 5 exchanges heat indirectly with the hot and humid air through the wall of the condenser chamber 1 .

[0049] The lower part of the condensed water interlayer 5 is provided with the first condensed water inlet 6, the upper part of the condensed water interlayer 5 is provided with the first condensed water outlet 7, the upper part of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com