Spiral friction type anchor device for fiber reinforced composite material rib pull cable

一种复合材料、纤维增强的技术,应用在建筑加强件、桥梁零件、结构要素等方向,能够解决粘结区端部弯折、剪切疲劳、加持区端部弯折等问题,达到增大旋转摩擦力、消除横向剪力、结构合理的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

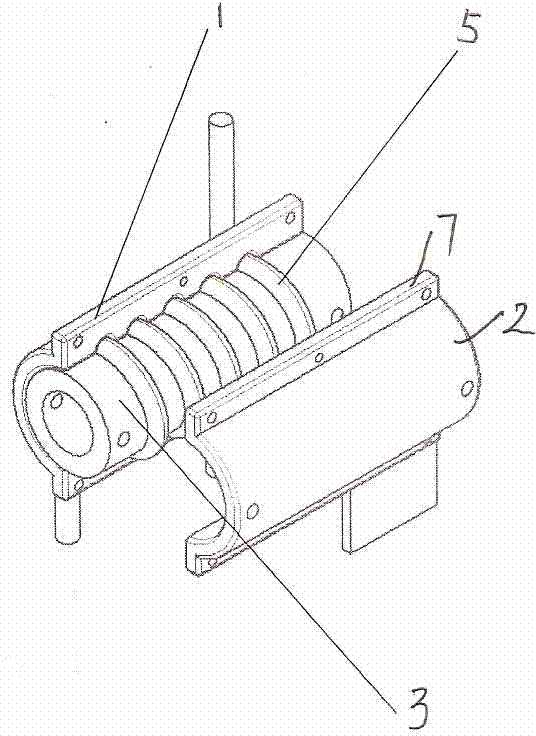

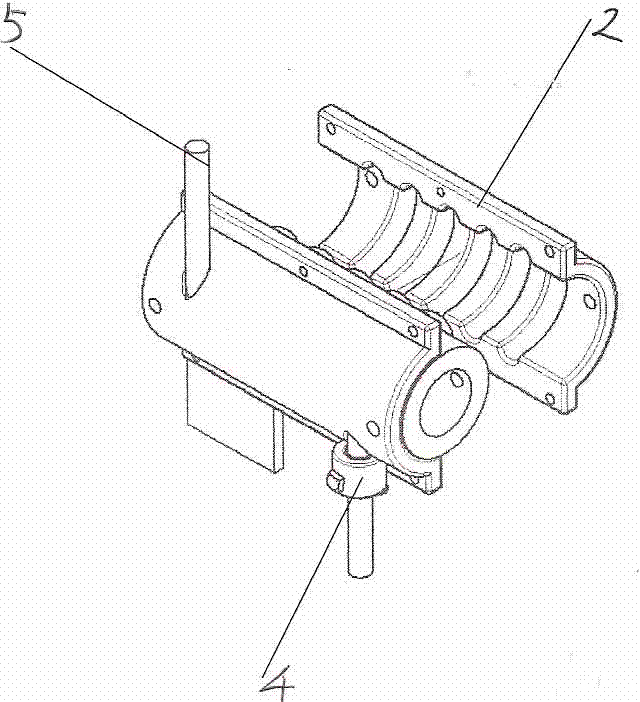

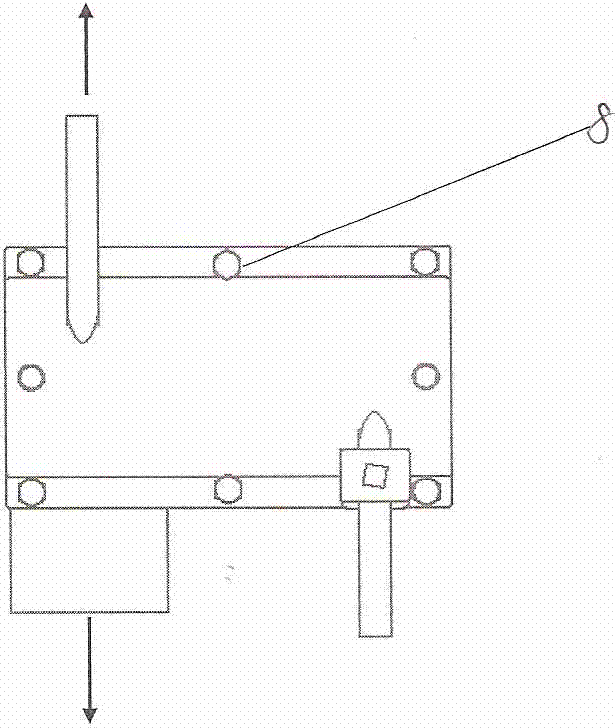

[0020] An adjustable pre-tightening force friction anchor applied to fiber-reinforced composite tendon cables, including two cover plates (A) 1 and (B) 2 with spiral grooves, and a column core with spiral grooves 3. A cable fastener 4; wherein the cross section of the spiral groove in the cover plate and the column core is semicircular with the same diameter, and the spiral grooves in the two cover plates and the column core cooperate with each other to form a space spiral groove with a circular cross section ; The cover plate A has an inlet hole and an output hole respectively at the starting point and the end point of the spiral groove, and the FRP tendon cable 5 with the same diameter as the spiral groove section passes through the inlet hole of the cover plate A and is wound in the spiral groove in the column core , and pass through the output hole of the cover plate A, the FRP tendon cable is wrapped by the surface of the space rotation groove formed by the cover plate and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com