Breaking device for sweeping and breaking all-in-one machine

A technology of a crushing device and an all-in-one machine, which is applied in the directions of track cleaning, cleaning methods, construction, etc., can solve the problems affecting the running of trains and hidden dangers of train operation, and achieve the effects of low production cost, compact structure and convenient use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further elaborated below.

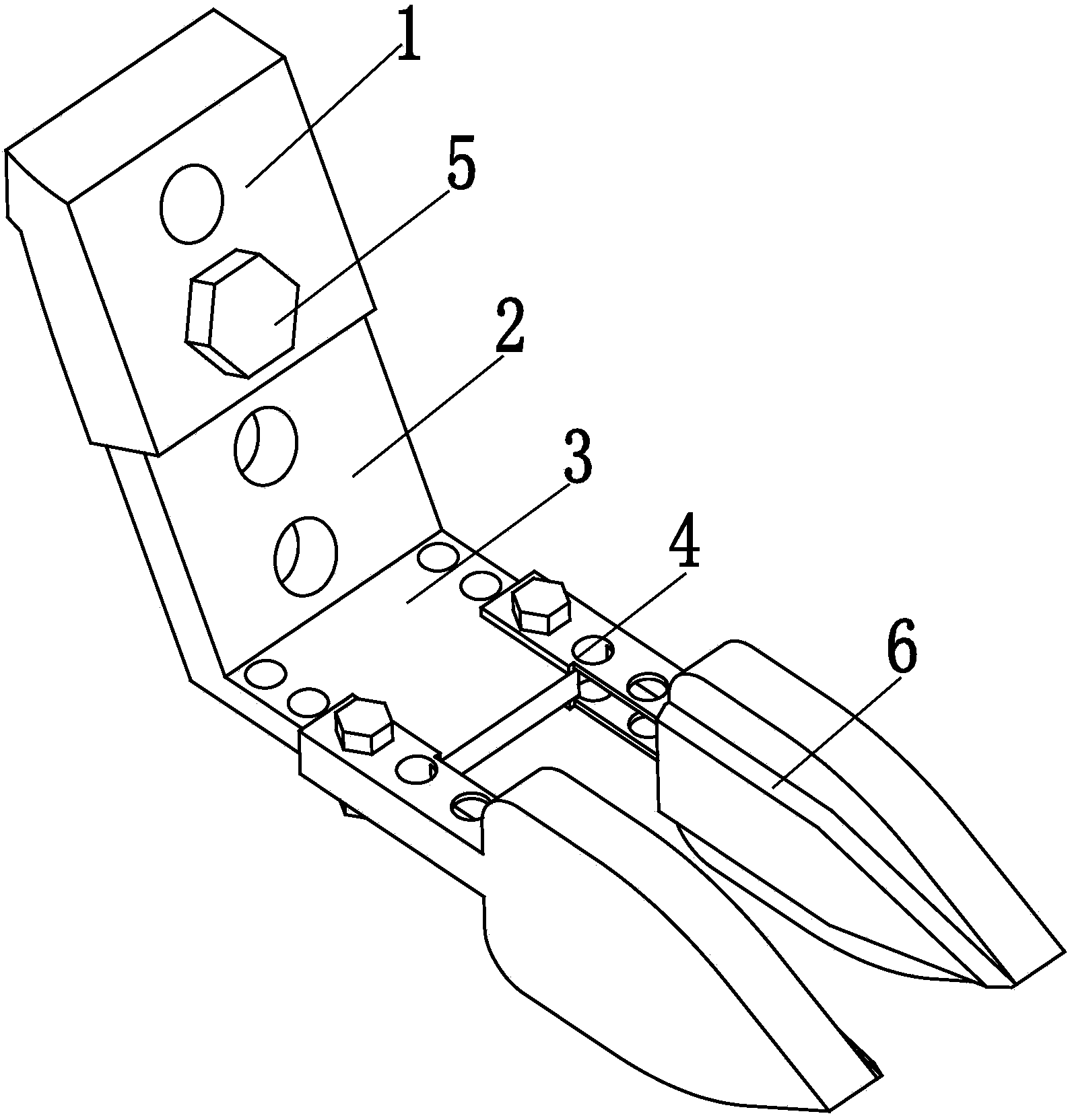

[0014] like figure 1 As shown, a crushing device for a cleaning and crushing integrated machine according to the present invention includes a vertical chute 1, a vertical slider 2, a horizontal chute 3, a horizontal slider 4, a locking bolt 5 and a deicing knife 6. The vertical slider 2 is installed on the vertical chute 1, and vertical limit holes are provided on the vertical chute 1 and the vertical slider 2; the horizontal chute 3 is fixed on the front end of the vertical chute 1, and the horizontal slider 4 is installed on the horizontal chute 3, and the horizontal slider 4 and the horizontal chute 3 are provided with horizontal limit holes, and locking bolts 5 are installed in the vertical limit holes and the horizontal limit holes; the deicing knife 6 is fixed on the front end of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com