A static load test steel beam device

A steel beam and experimental technology, which is applied in the test of basic structure, construction, basic structure engineering, etc., to achieve the effect of improving the bending resistance, increasing the load-bearing requirements of large tonnage, and the effect of simple and practical structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

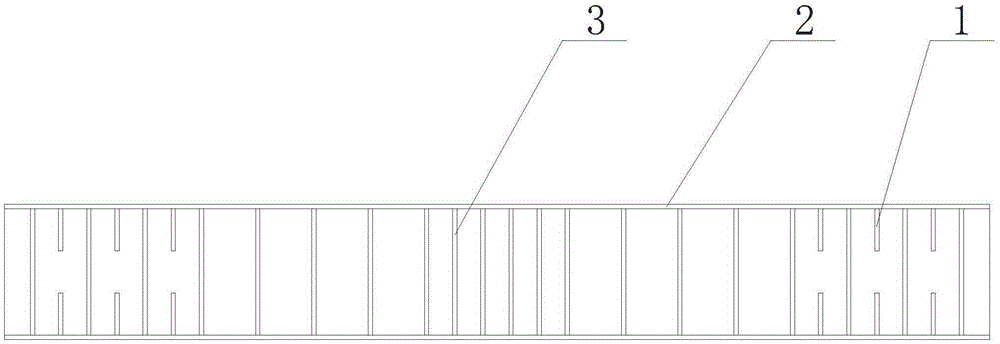

[0015] Such as figure 1 As shown, a static load test steel beam device includes a steel beam support 2, and the cross section of the steel beam support 2 is square. The middle position of the steel beam support 2 is provided with several webs 3 with different intervals. A stiffening device is arranged between the webs at the edge positions of the steel beam support 2 .

[0016] In this embodiment, the stiffening device includes a stiffening rib 1 arranged between the webs 3 , and the stiffening rib 1 is installed on the inner side of the steel beam support 2 .

[0017] The stiffener 1 is a metal plate whose length is 1 / 3-1 / 2 of the web.

[0018] Considering the actual use, the distance between the webs 3 in the middle of the steel beam bracket 2 is 200 mm. The distance between the webs 3 at the edges of the steel beam support is 400 mm. The stiffener 1 is installed on the inner side of the steel beam support by welding. The stiffener 1 is made of steel plate, and the leng...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com