Vehicle knapping machine

A technology for rock drilling and rock drilling, which is applied in cutting machinery, slitting machinery, stone processing tools, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

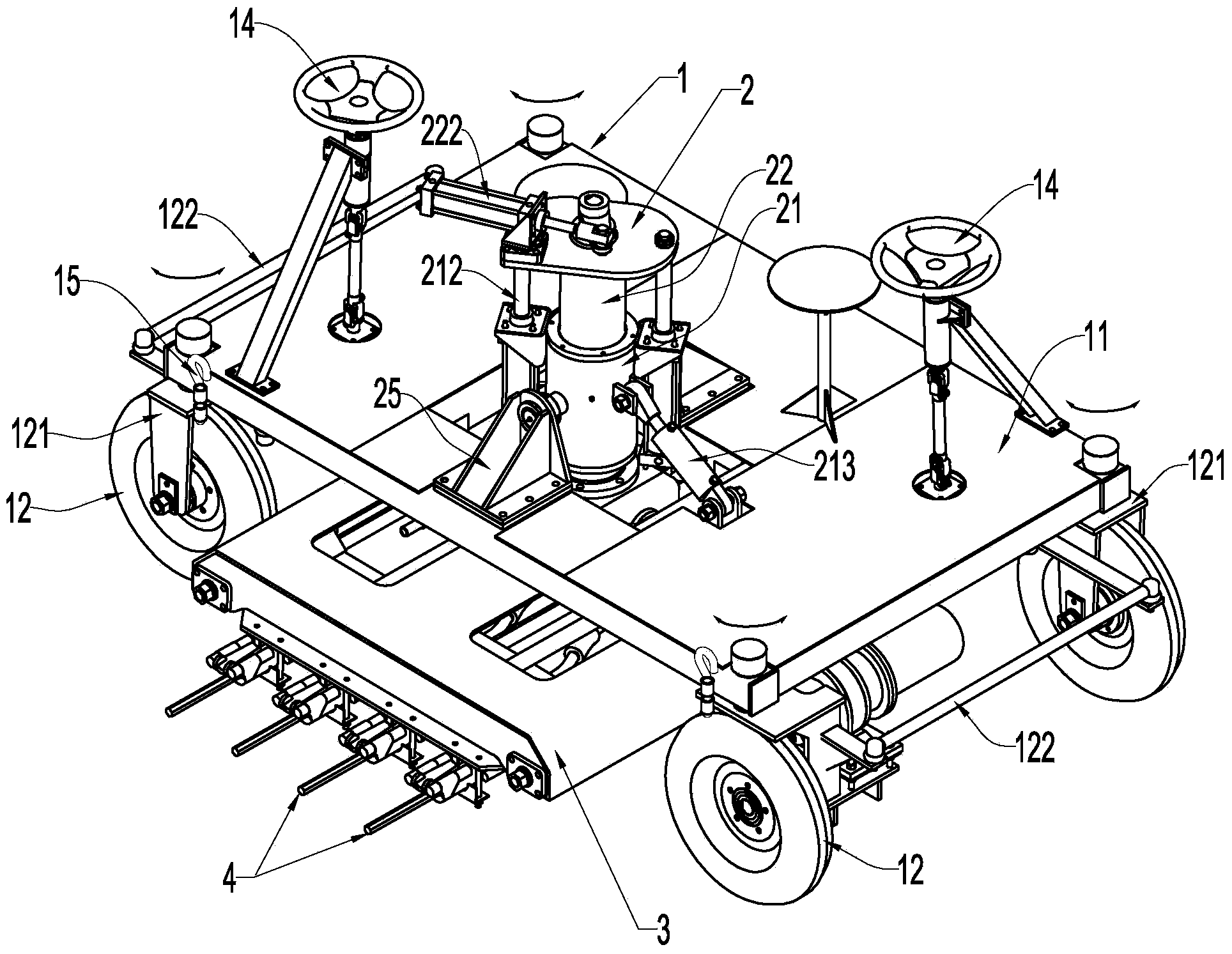

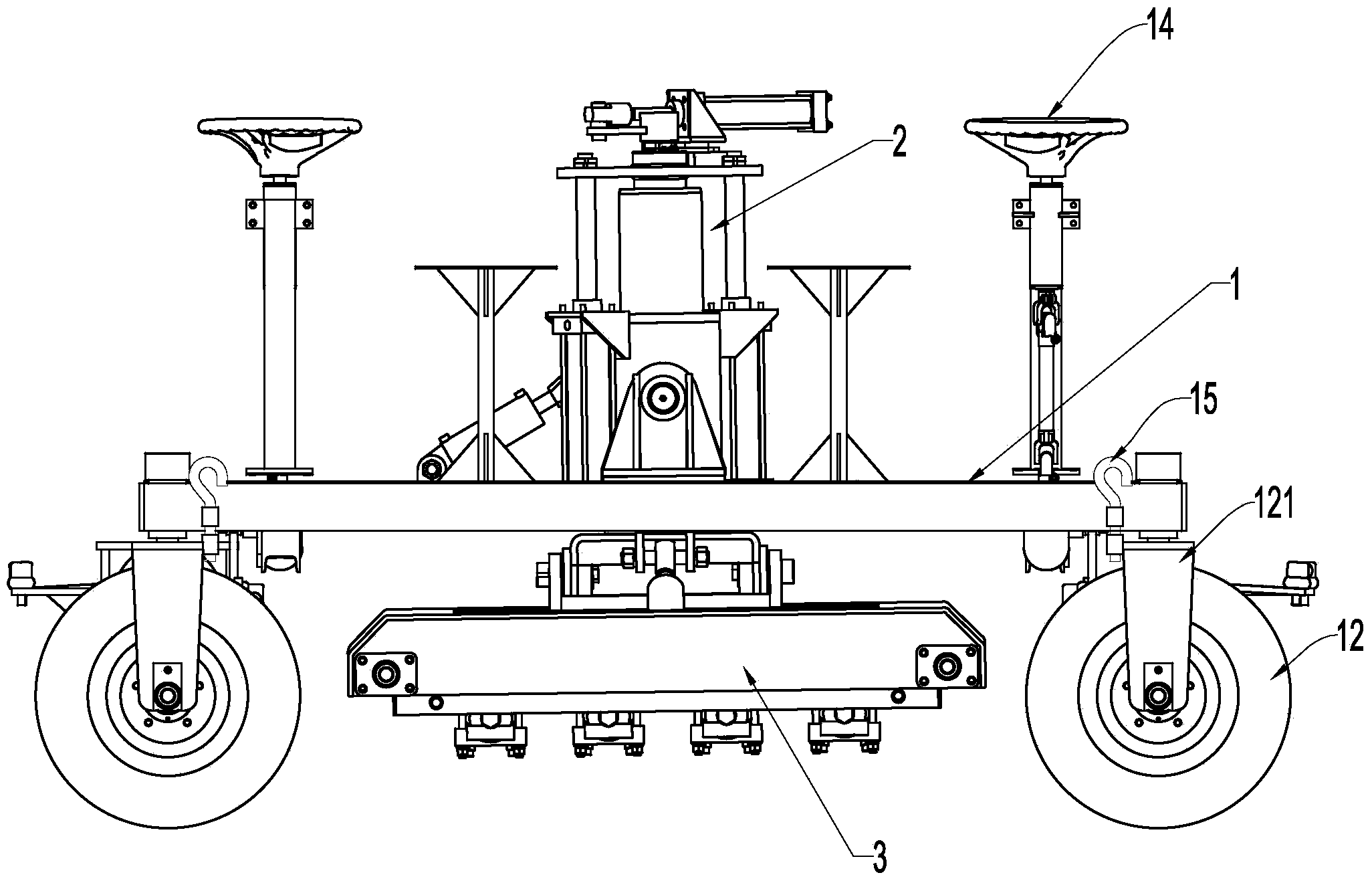

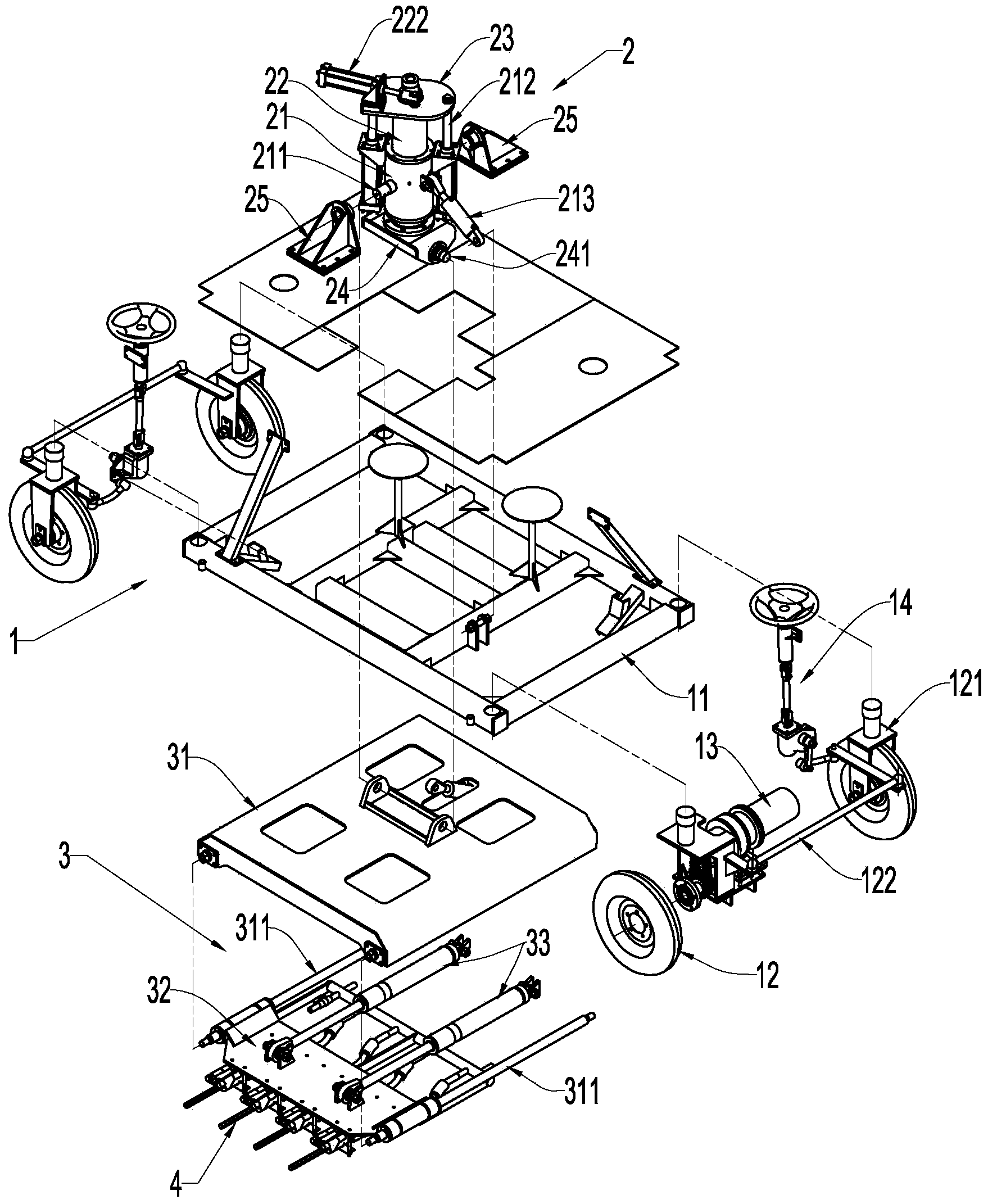

[0028] refer to figure 1 , figure 2 with image 3 , a vehicle-mounted rock drill, including a motor vehicle assembly 1, a universal mechanism 2, a propulsion mechanism 3, a rock drill 4 and a pressure station; the motor vehicle assembly 1 includes a vehicle frame 11, driving wheels 12, power 13 and steering wheel components 14. The driving wheel 12 is movably positioned on the four corners of the vehicle-carrying frame 11 through the wheel frame 121. The wheel frame 121 and the vehicle-carrying frame 11 are provided with corresponding positioning holes, which are inserted by means of a positioning pin 15 to form a position locking relationship of the driving wheel 12 to prevent The drive wheel 12 yaws left and right, resulting in shaking; the front and rear drive wheels of the vehicle frame 11 are all provided with a set of steering wheel assembly 14; 14 controls for synchronous rotation. Wherein a pair of drive wheels 12 is driven by power 13, and power 13 can be electric...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com