Vehivle disc brake

A technology for disc brakes and vehicles, which is applied in the direction of brake types, brake components, axial brakes, etc., and can solve problems such as troublesome riveting operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

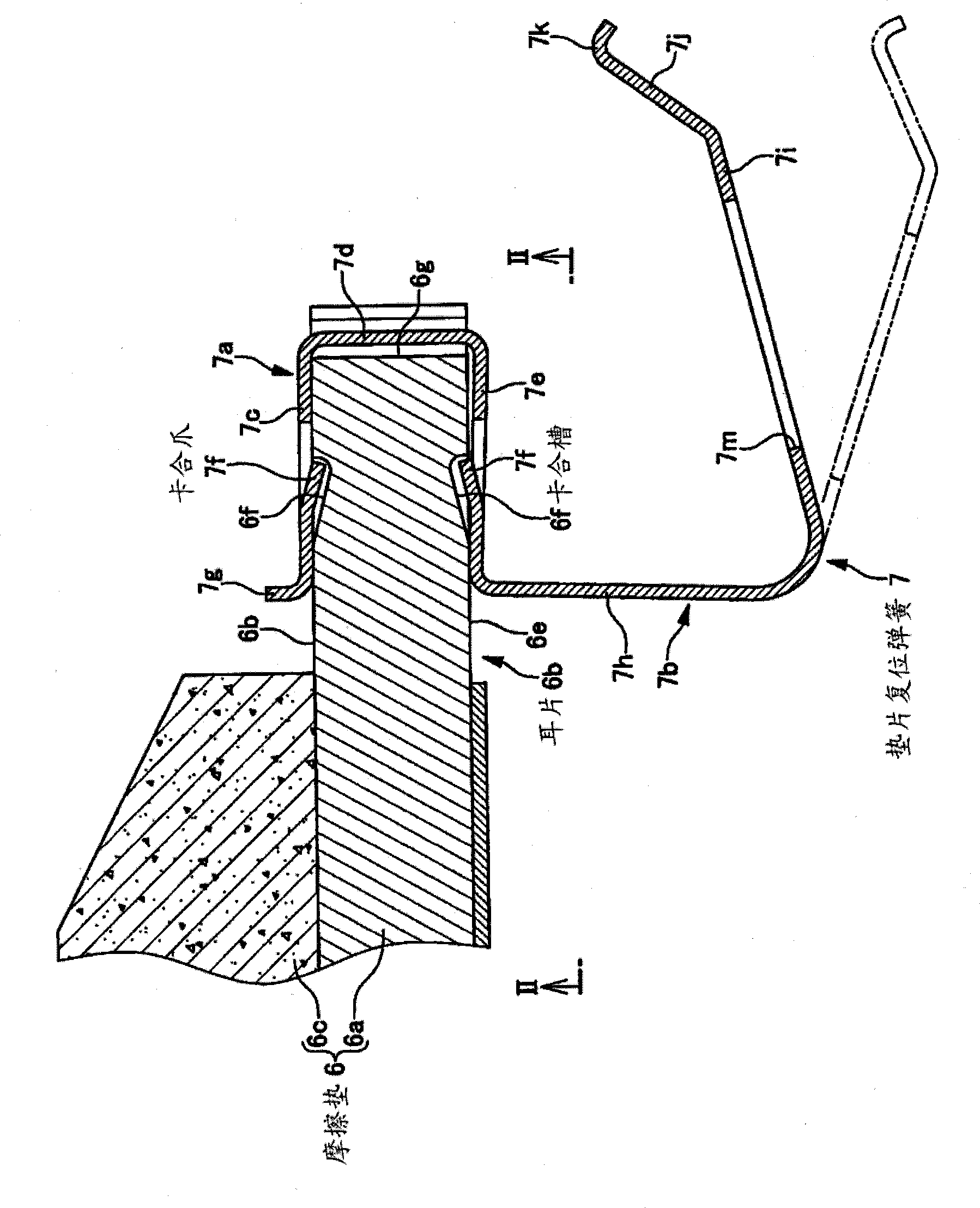

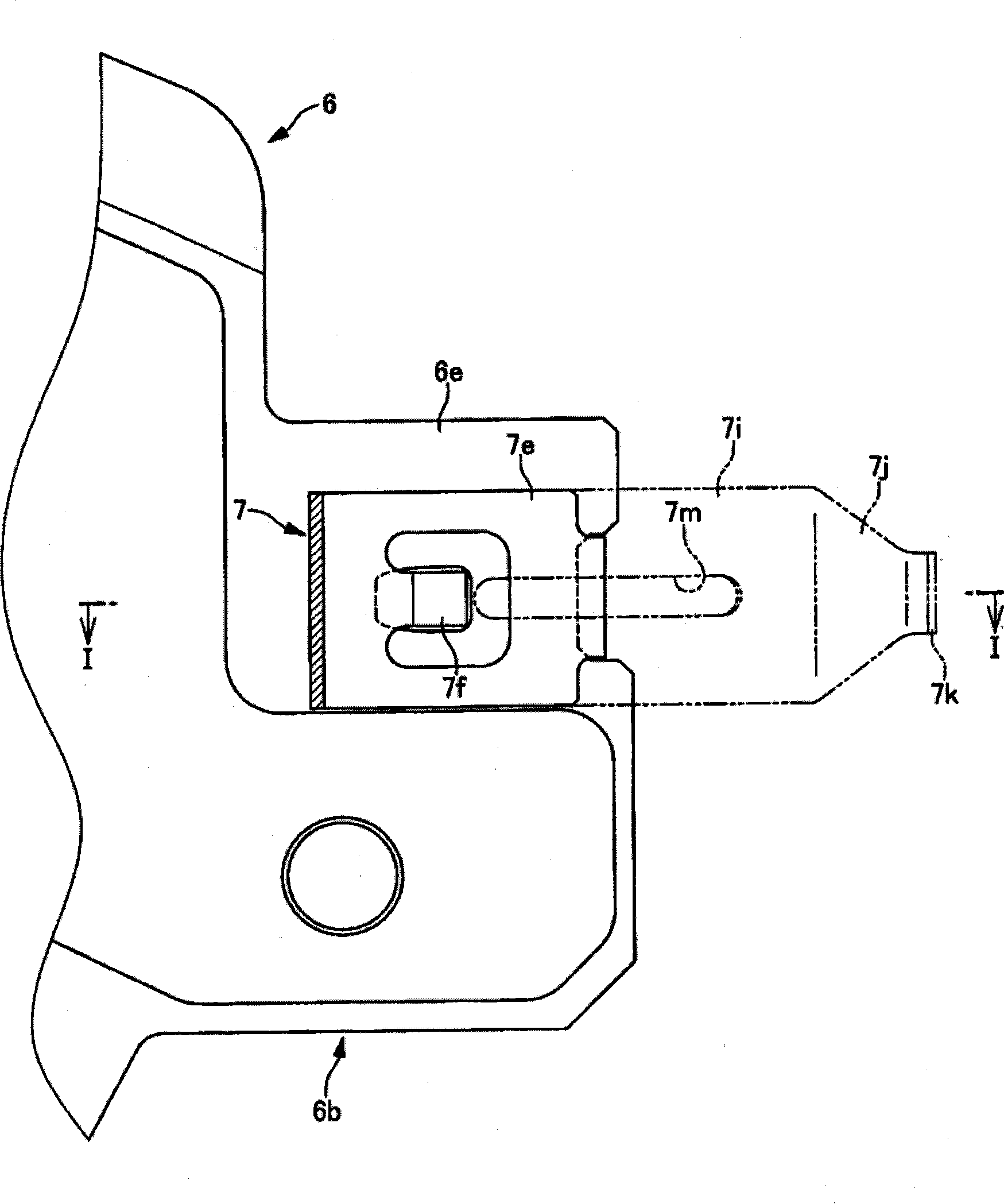

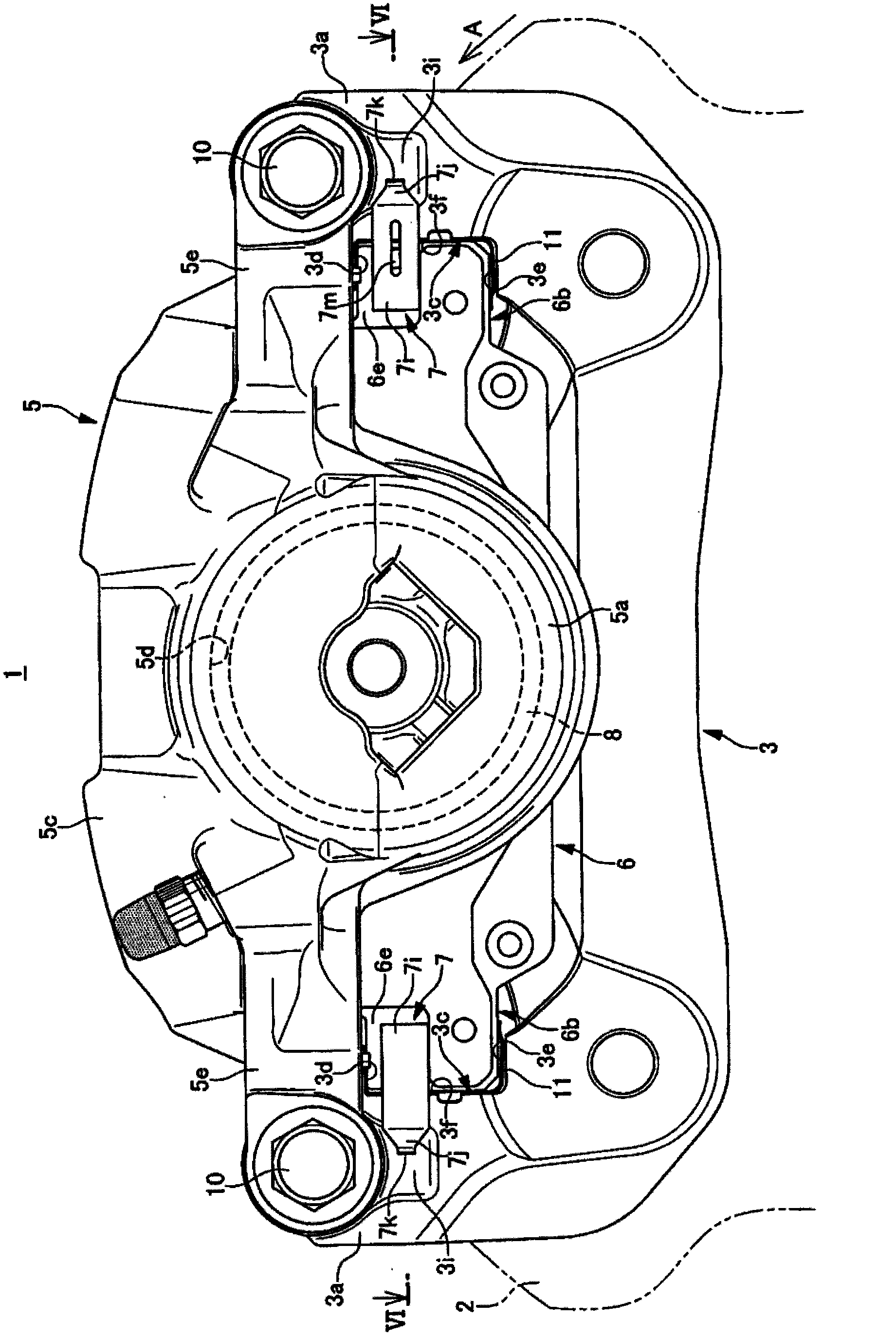

[0073] Figure 1~Figure 9 This shows a disc brake for a vehicle according to an embodiment. The arrow mark A is the direction of rotation of the disc rotor that rotates integrally with the front wheels when the vehicle moves forward. In the following, "disk turning-out side" and "disk turning-in side" refer to the disk turning-out side and disk turning-in side when the vehicle is moving forward.

[0074] The disc brake 1 for a vehicle includes a disc rotor 2, a caliper holder 3, a caliper body 5, a pair of friction pads 6 and 6, and four pad return springs 7. The disc rotor 2 rotates integrally with the wheel. The caliper bracket 3 is fixed to the vehicle body on one side of the disc rotor 2. The caliper body 5 is supported by the caliper support arms 3a, 3a of the caliper holder 3 via a pair of sliding pins 4, 4 so as to be movable in the axial direction of the disc. A pair of friction pads 6 and 6 are arranged inside the action portion 5a and the reaction portion 5b of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com