Fully-sealed dustproof structure of fixed belt tension pulley component

A technology of dust-proof structure and tensioner, which is applied to belts/chains/gears, engine seals, components with teeth, etc., and can solve problems such as high cost, inability to meet dust-proof capability requirements, and complicated dust-proof covers , to achieve the effect of low cost, improved product life and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

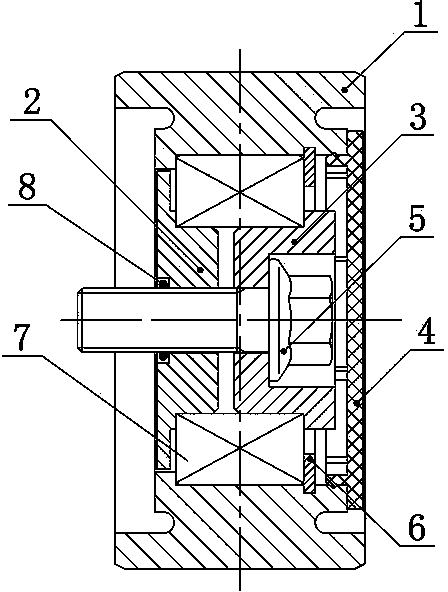

[0010] The present invention will be further described below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited to the following description.

[0011] like figure 1 As shown, a fixed belt tensioner assembly is fully sealed and dust-proof structure, which includes pulley 1, bearing retaining ring I2, bearing retaining ring II3, dust cover 4, bearing 7 and elastic retaining ring 6 for holes, bearing 7 Cooperate installed on the inner side of the pulley 1, one side of the inner hole of the pulley 1 is provided with a step to limit the outer ring of the pulley 1, and the other side is sequentially provided with a circlip groove for the hole and a slot for the dust cover, and the circlip 6 for the hole is installed on the In the groove of the elastic circlip for the hole, the elastic circlip 6 for the hole is in contact with the other side of the outer ring of the bearing 7, and the two sides of the inner ring of the bear...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com