Measuring system for detecting repeated positioning accuracy of manipulators

A technology of repeated positioning accuracy and measurement system, applied in the field of measurement systems, can solve the problems of budget constraints, large space constraints, and expensive equipment for laser tracking measurement, so as to improve the repeated positioning accuracy, with little influence of external conditions, and easy to use. The effect of saving records

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

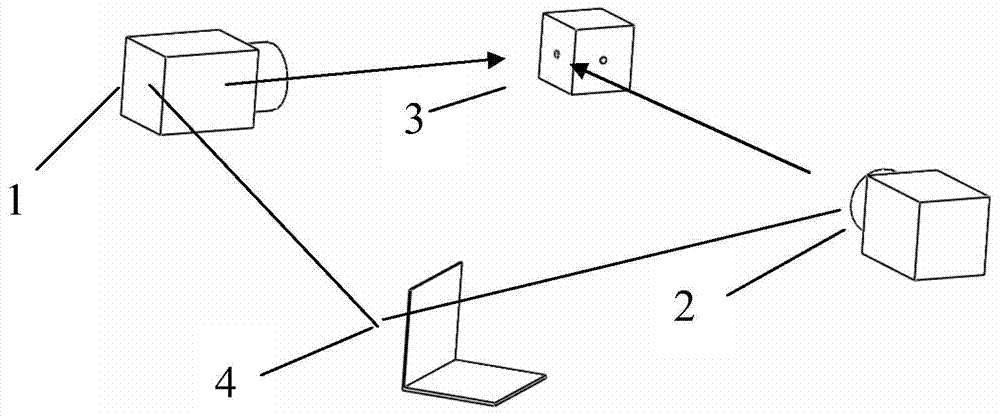

[0013] refer to figure 1 . In the embodiment described below, the measurement system for detecting the repetitive positioning accuracy of the manipulator mainly includes a first camera component 1 and a second camera component 2 fixedly placed in an orthogonal direction, a measured object 3 and a computing component 4 . The first camera assembly 1 and the second camera assembly 2 are equipped with sensors, and when the measured object 3 enters the field of view of the first camera assembly 1 and the second camera assembly 2 and the position is stable, the calculation assembly is automatically triggered to execute the calculation program. The measured object 3 is connected to the end of the manipulator, and can move with the manipulator so that the measured object 3 is placed within the common field of view of the first camera assembly 1 and the second camera assembly 2 . The measured object 3 has a mounting hole that can be installed at the end of the manipulator, and there a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com