Calibration device of gear transmission error detection equipment

A technology of gear transmission and error detection, which is applied in the direction of machine gear/transmission mechanism testing, etc., can solve the problems of no error detection equipment calibration, encoder calibration error evaluation, grating encoder field calibration, etc., to achieve accurate and reliable measurement data, Improved reliability and ease of operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

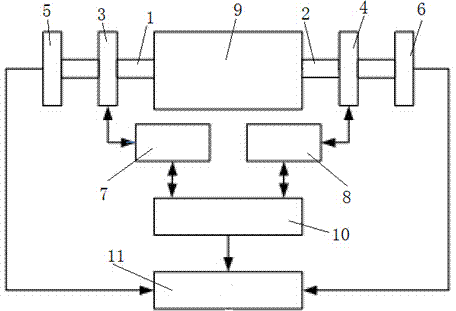

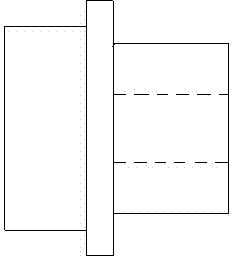

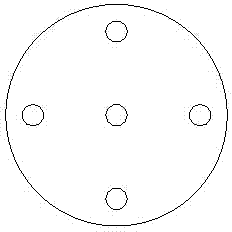

[0024] Such as Figure 1~Figure 3 As shown, a calibration device for gear transmission error detection equipment includes a gear transmission input shaft acquisition device and an output shaft acquisition device, and the input shaft acquisition device includes a first polygonal prism 3, a first autocollimator 7 And the first grating encoder 5, the first polygonal prism 3 has a regular prism-shaped gauge with accurate angles, its measuring surface has good optical reflection performance, and the number of measuring surfaces is generally 8, 12, 23, 24 and 36, etc., up to 72 sides, it is often used to verify angle measurement tools, such as optical indexing head, rotary table, multi-tooth indexing table, etc., when verifying, use the autocollimator reading, the first multi- One end of the facet prism 3 is fixedly connected to the input shaft, and the other end is fixedly connected to the rotating shaft of the first grating encoder 5. The first autocollimator 7 is aligned with the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com