Longitudinal sliding test method for eliminating longitudinal force deviation of tire

A test method and longitudinal force technology, applied in the field of tire dynamic characteristics test research, can solve the problems of complex tire model form, difficult to establish a simple and high-precision tire model, etc. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

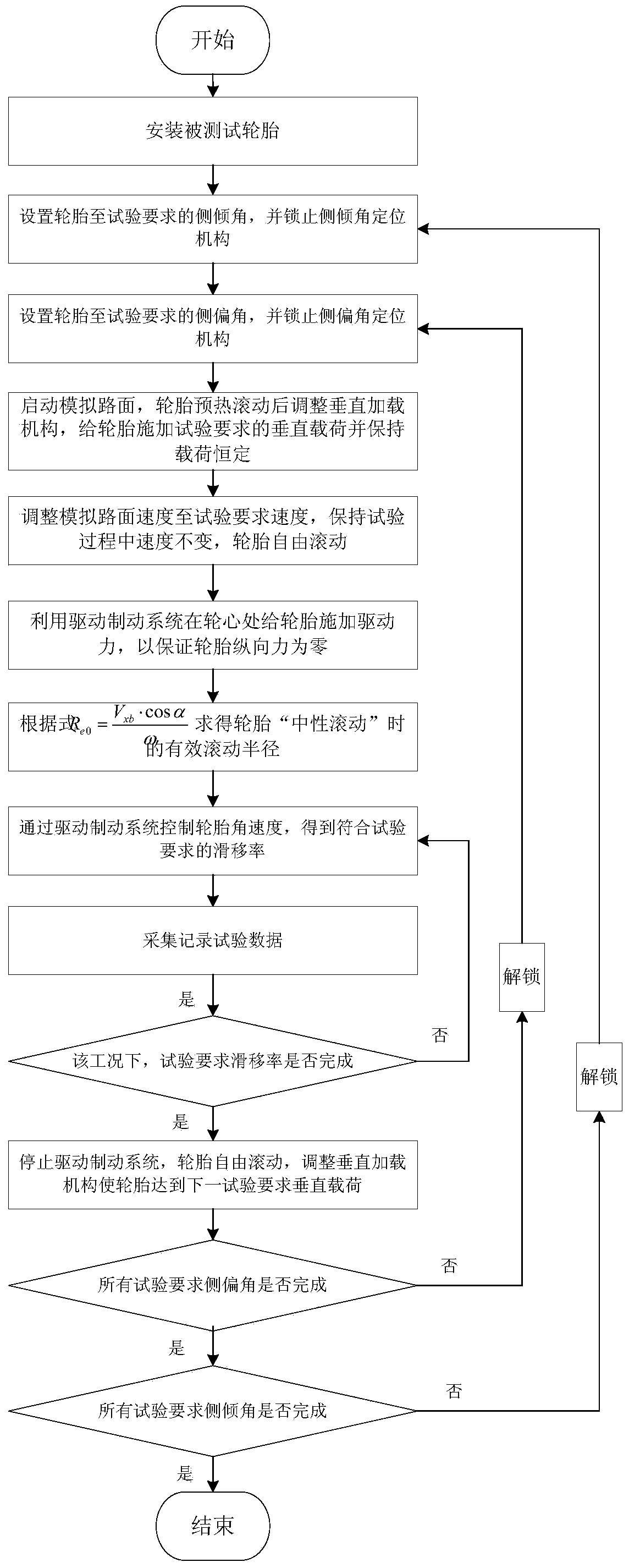

[0032] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

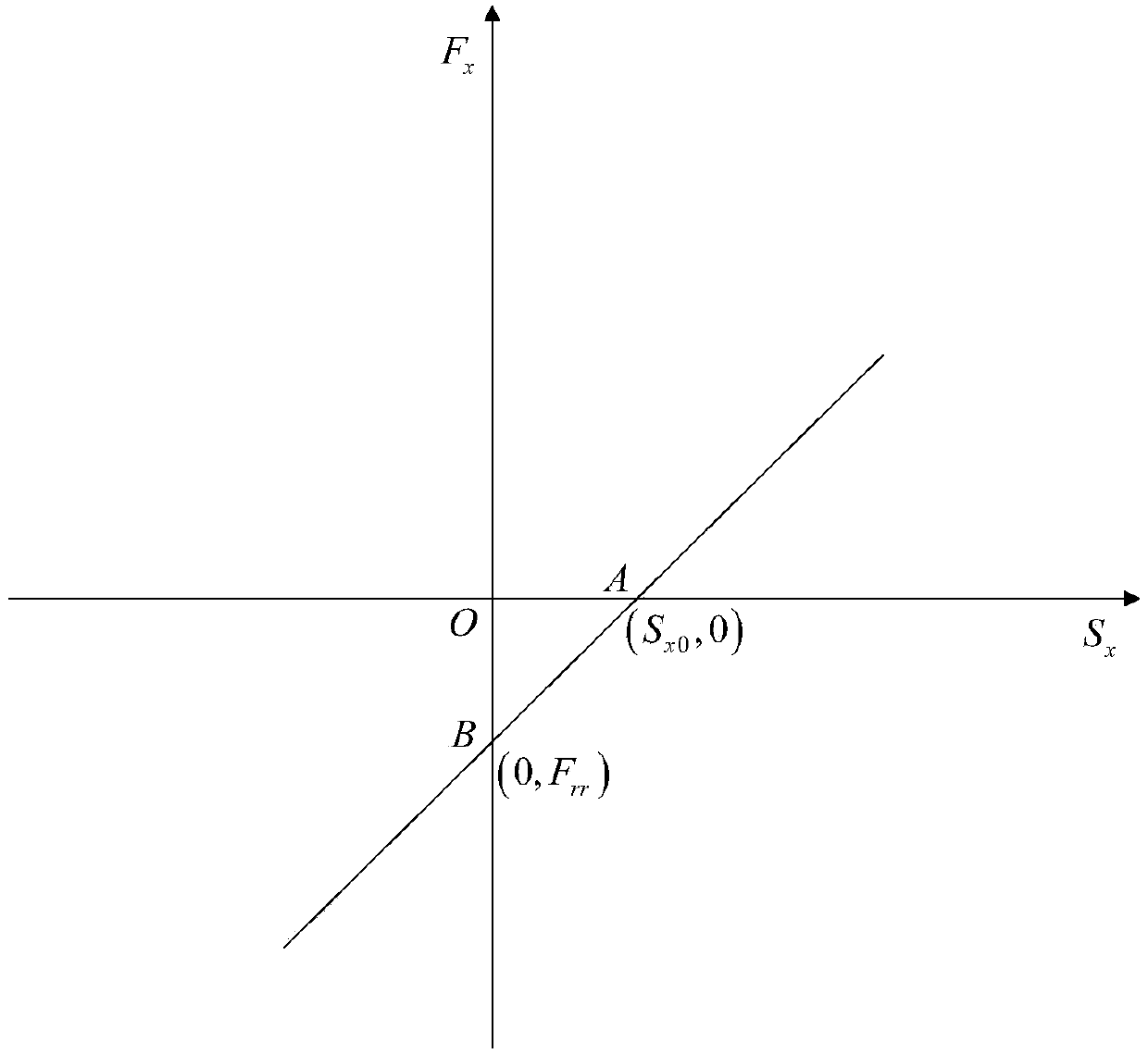

[0033] figure 1 is the longitudinal force F of the tire in the free rolling state x ——Slip rate S x Schematic diagram of the relationship curve, when the tire is rolling freely, due to the existence of the rolling resistance moment, the longitudinal force F x ——Slip rate S x The curve does not pass the origin, and the effective rolling radius of the tire at this time is where V x is the longitudinal velocity of the wheel, ω is the rolling velocity of the wheel, such as figure 1 Point B in .

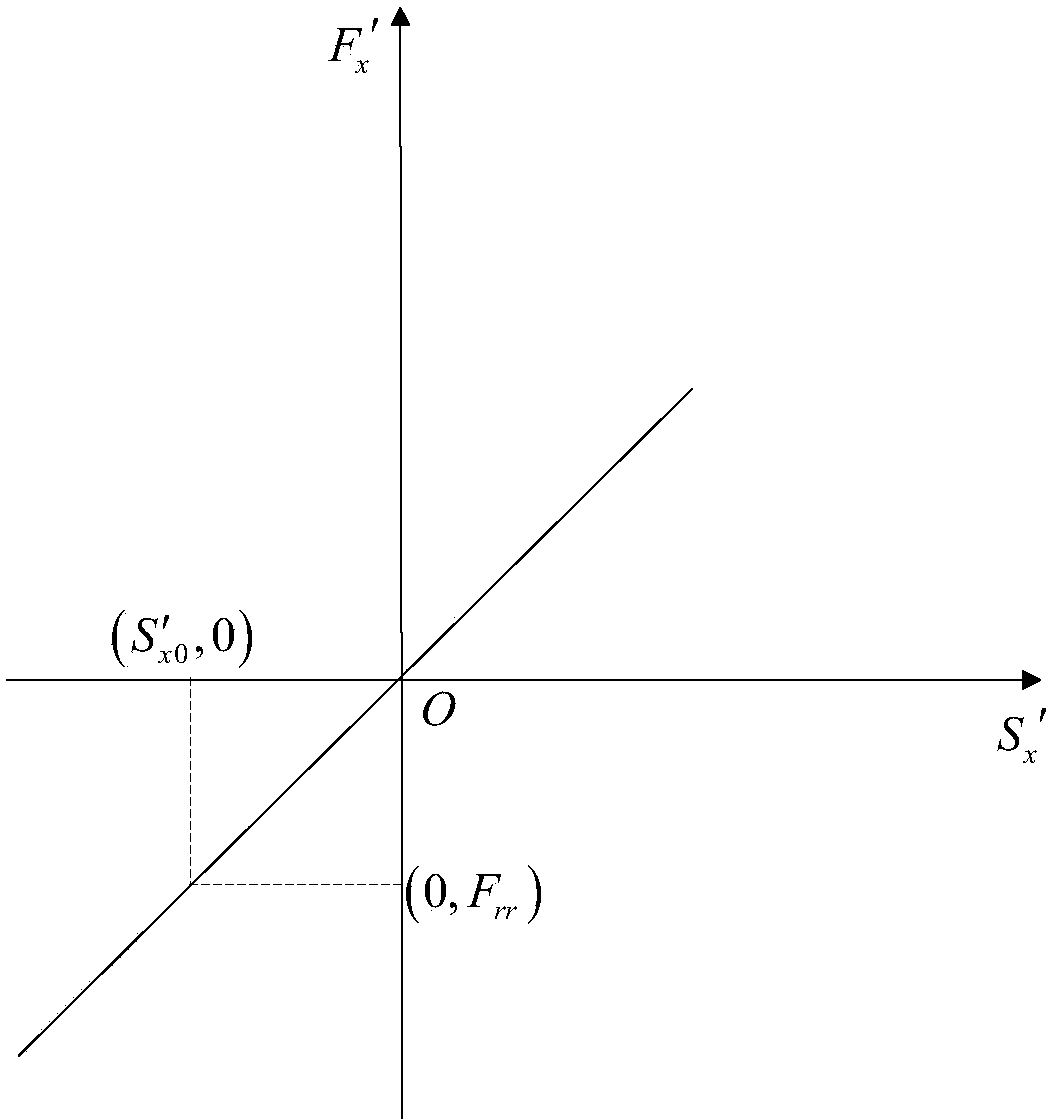

[0034] figure 2 is the longitudinal force F of the tire in the "neutral rolling" state x ′——slip rate S x ′Schematic diagram of the relationship curve, when the wheel is "neutral rolling", the rolling resistance of the tire is zero and the effective rolling radius is where V x ′, ω′ are the longitudinal velocity and rolling ve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com