Stratified sampling device for grains

A sampling device, grain technology, applied in the direction of sampling devices, etc., can solve problems such as complex structure, and achieve the effect of simple structure, low cost, and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Below in conjunction with accompanying drawing, the specific embodiment that the present invention creates is described in detail:

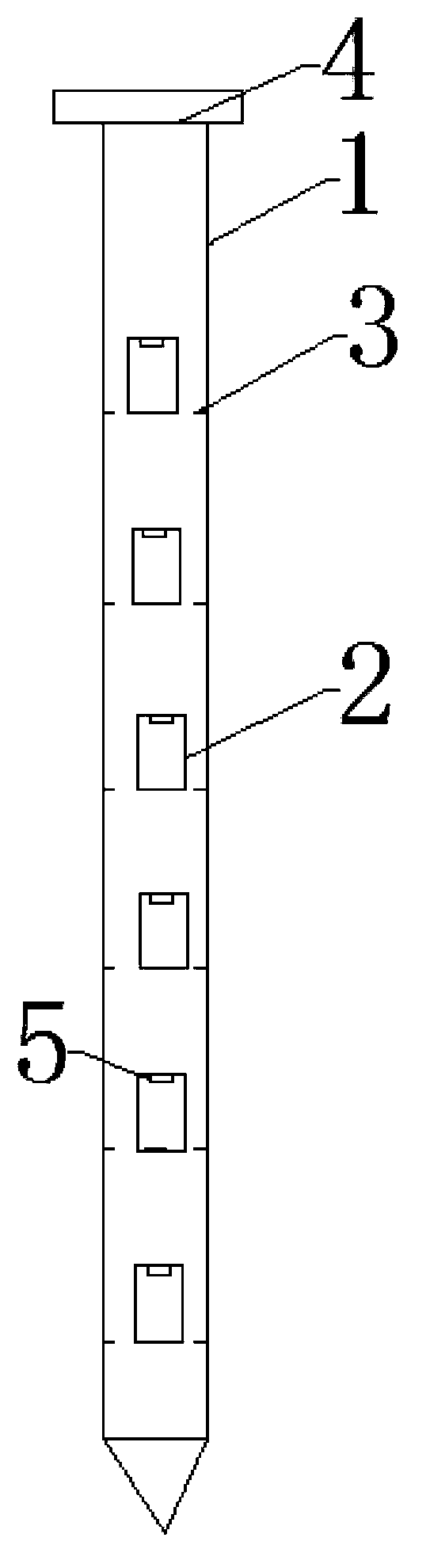

[0016] Such as figure 1 Shown:

[0017] A grain layered sampling device, comprising a body 1, the body 1 is a single-layer cylinder, the cylinder is divided into a plurality of cavities by partitions 3, each cavity is provided with a side wall Opening 2, each of the openings 2 is provided with a baffle, each of the baffles is provided with a pressure sensor 5, each of the pressure sensors 5 is connected to the power supply in the column, and the pressure sensor 5 is connected with the electric switch that controls corresponding described baffle plate. Due to the adoption of the above technical solution, the present invention adopts a single-layer cylinder, which has a simple structure and low cost. At the same time, due to the setting of the pressure sensor, as long as the present invention is inserted into the grain, the baffle will aut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com