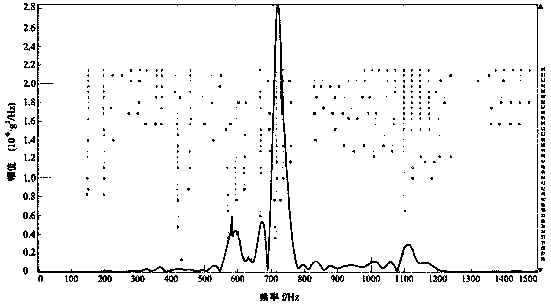

Spindle system operational modal analysis method based on pulse excitation response signal cross-power spectrum function

A cross-power spectrum and response signal technology, applied in the field of operational modal analysis, can solve problems such as low test efficiency, slow calculation speed, and poor error control, and achieve the effects of reducing equipment requirements, good error control, and high accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

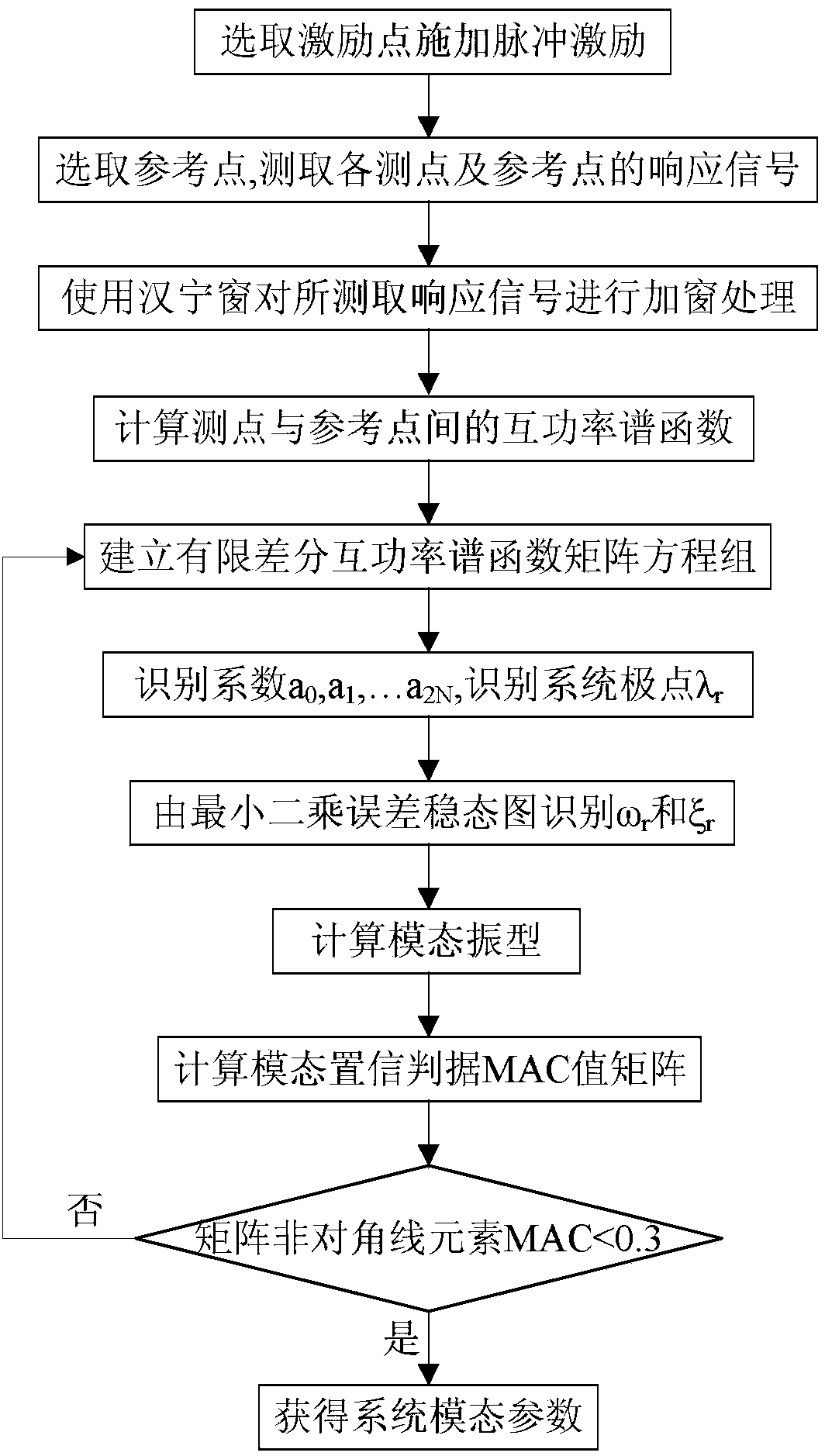

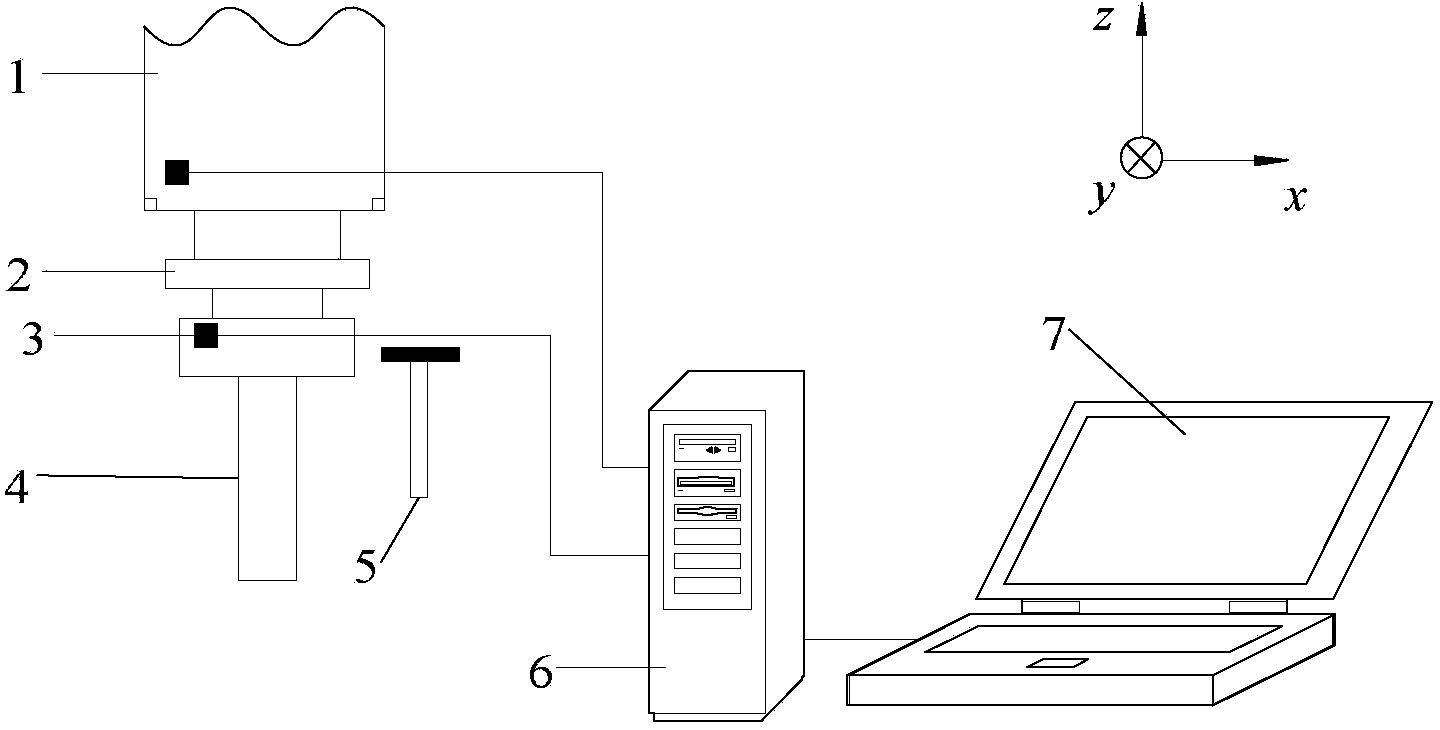

[0026] The present invention will be further described below in conjunction with the accompanying drawings.

[0027] refer to Figure 1 to Figure 6 , a method for analyzing the operating mode of the spindle system based on the cross power spectrum function of the impulse excitation response signal, comprising the following steps:

[0028] 1) Select an excitation point on the tool handle of the spindle system, and use a steel hammer to perform pulse excitation on the spindle system at the selected excitation point;

[0029] Select the response point that is closer to the excitation point and has a larger response signal amplitude as the reference point;

[0030] Response measuring points are arranged at the reference point and each key geometric model node reflecting the main shaft mode shape;

[0031] 2) collecting the response signals generated by the reference point and the response point after the pulse excitation;

[0032] 3) Perform band-pass filtering on the collected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com