Goods discharging device of vending machine

A vending machine and shipping device technology, which is applied to instruments, coin-operated equipment for distributing discrete items, and coin-operated equipment for distributing discrete items, etc. Rules and other issues, to achieve the effect of low delivery efficiency, convenient shipment, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

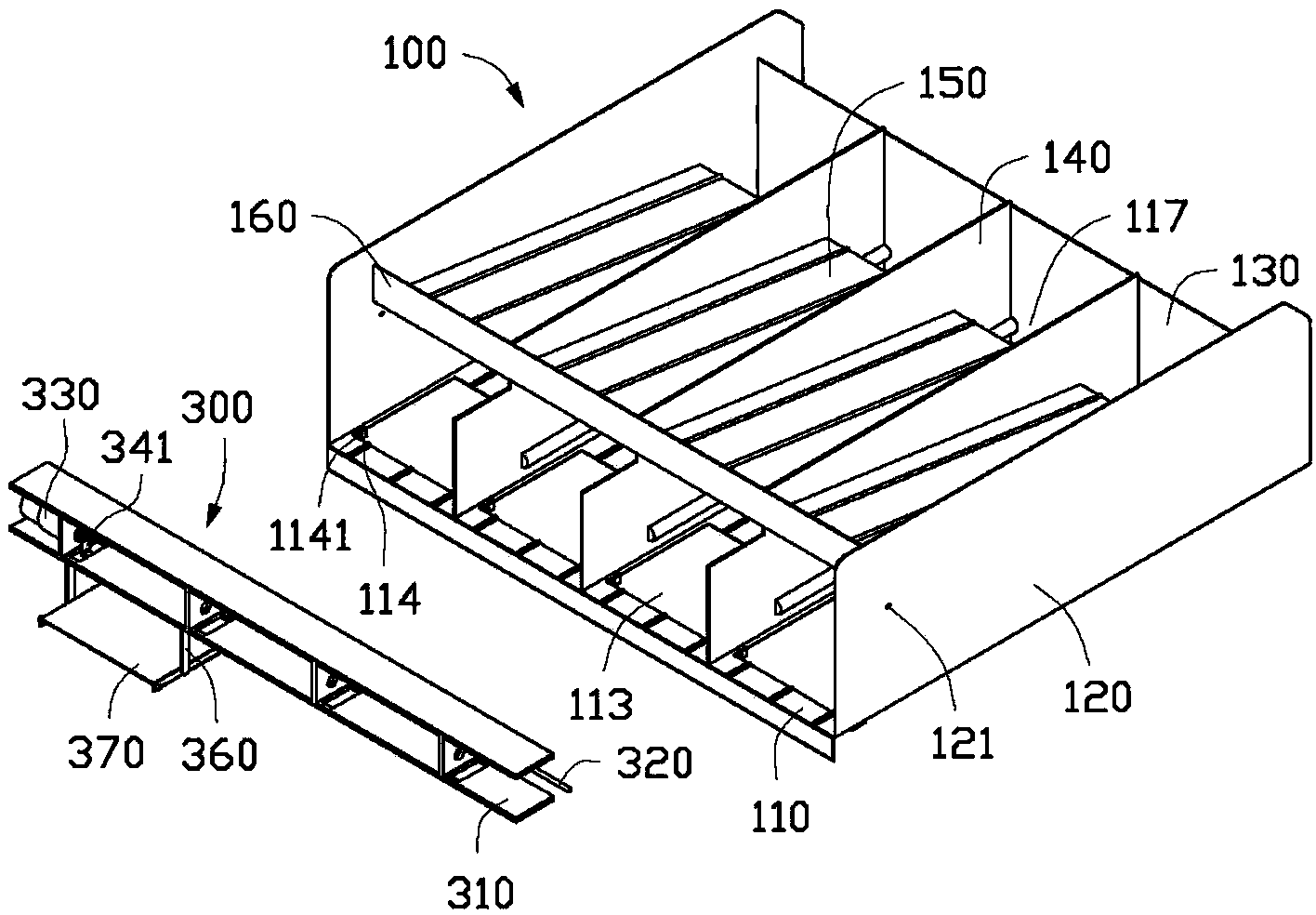

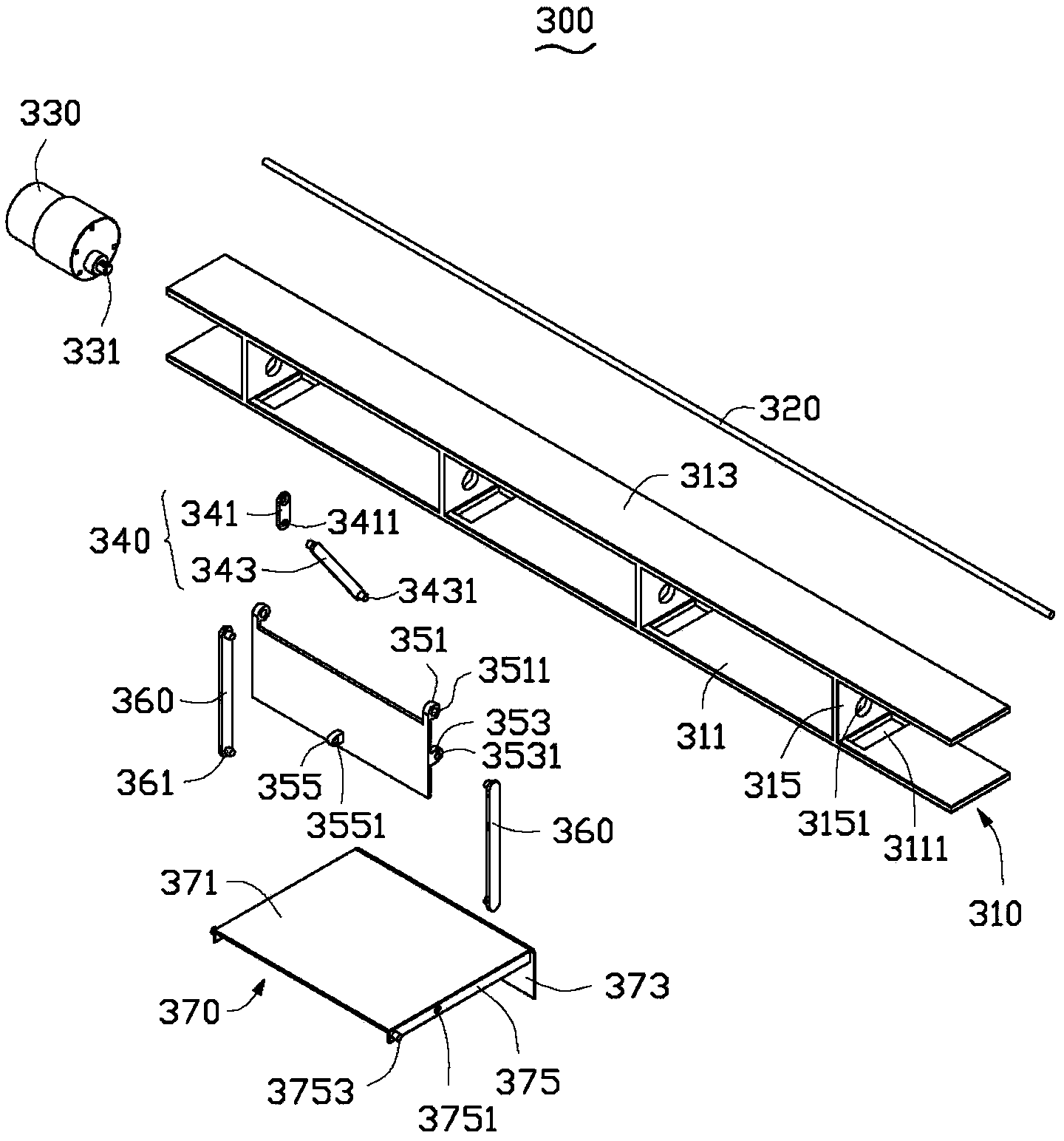

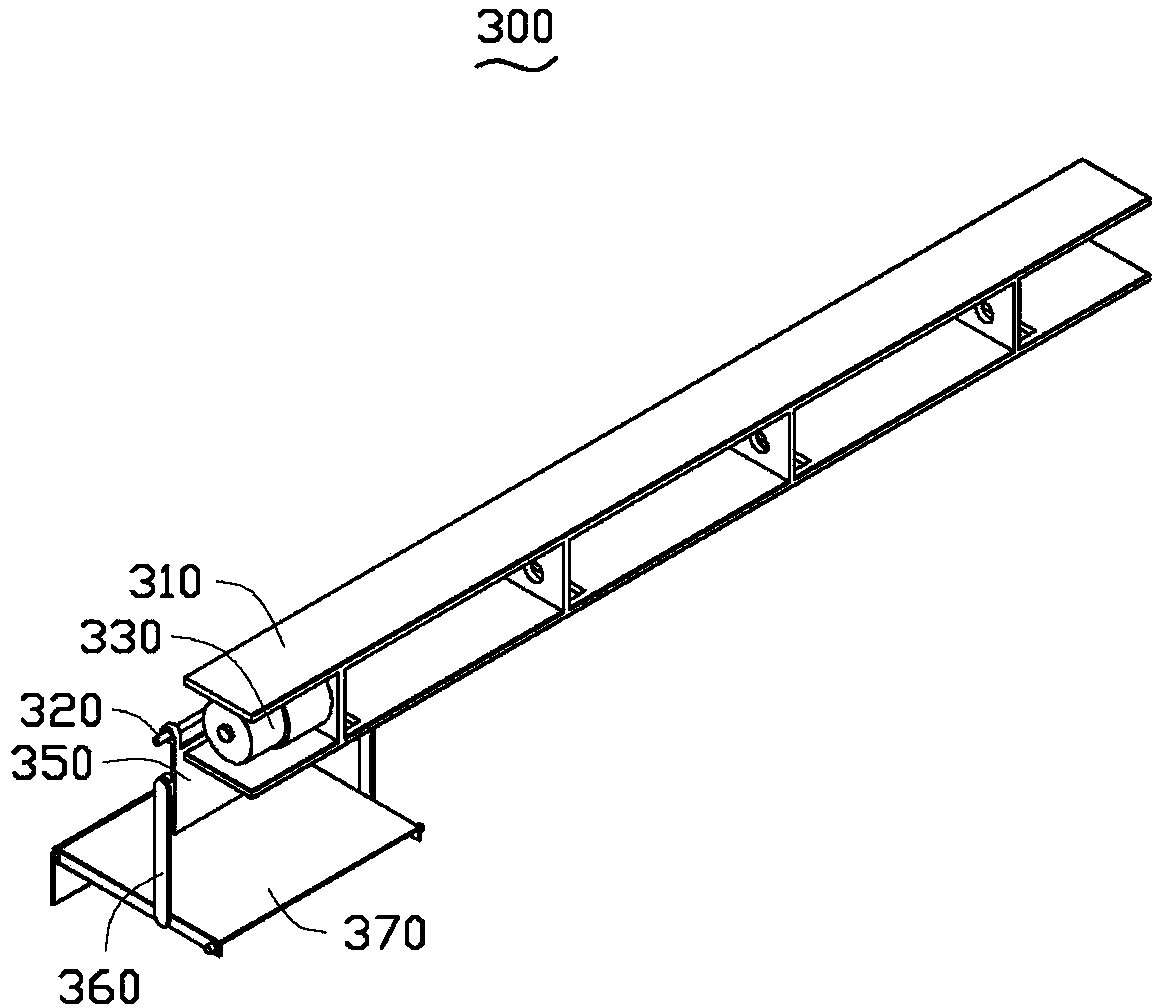

[0024] see figure 1 and Figure 5 , In a preferred embodiment of the present invention, a delivery device for an automatic vending machine includes a pallet 100 and a delivery mechanism 300 installed on the pallet 100 . Several commodities 400 with a circular cross section, such as beverages, cans, etc., can be placed on the pallet 100 .

[0025] The pallet 100 includes a bottom plate 110 , side plates 120 , a rear plate 130 and a plurality of partitions 140 . The two side panels 120 are located on opposite side edges of the bottom panel 110 . The plurality of partitions 140 are installed on the bottom plate 110 and located between the two side plates 120 . In one embodiment, the plurality of partitions 140 are parallel to each other and parallel to the two side panels 120 respectively, and the two side panels 120 and the plurality of partitions 140 are substantially perpendicular to the bottom panel 110 . The rear panel 130 is mounted on the rear side of the bottom panel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com