Adjustable pitch pins

A technology of adjusting spacing and pin insertion, which is applied in the direction of contact parts, etc., can solve the problems of inability to adjust spacing and poor adaptability of pin insertion, and achieve the effect of simple structure, strong adaptability and convenient installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with accompanying drawing and embodiment:

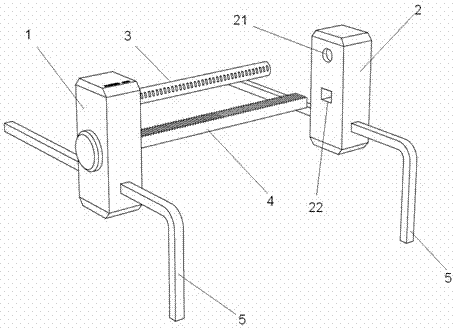

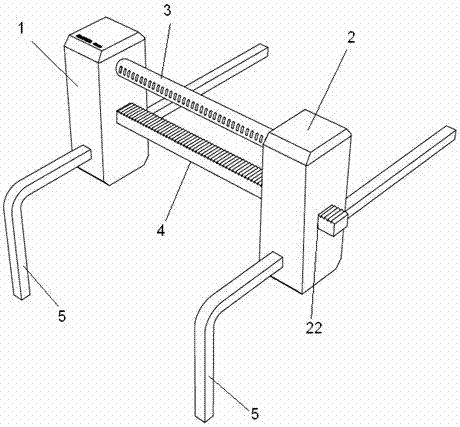

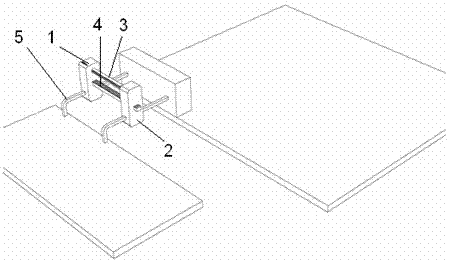

[0023] figure 1 It is a schematic diagram of the uninstalled structure of the pins with adjustable spacing in the present invention, figure 2 It is a schematic diagram of the structure of the pitch-adjustable contact pin of the present invention after installation. A pitch-adjustable contact pin includes: a male connector 1 and a female connector 2. The male connector 1 has a fixing bar 3 and the female connector 1 The head 2 has a recess 21 matching the fixing strip 3, one end of a non-reverse strip 4 is installed on the male head 1, and a second anti-reverse strip hole 22 is opened on the female head 2, and the non-reverse strip 4 passes through the second The anti-reverse hole 22; both the male connector 1 and the female connector 2 are passed through by the needle-shaped conductor 5. In the specific use process of the present invention, the fixing stri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com