Brushless permanent magnet motor

A technology of permanent magnet motor and magnet group, which is applied in the direction of electrical components, electromechanical devices, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

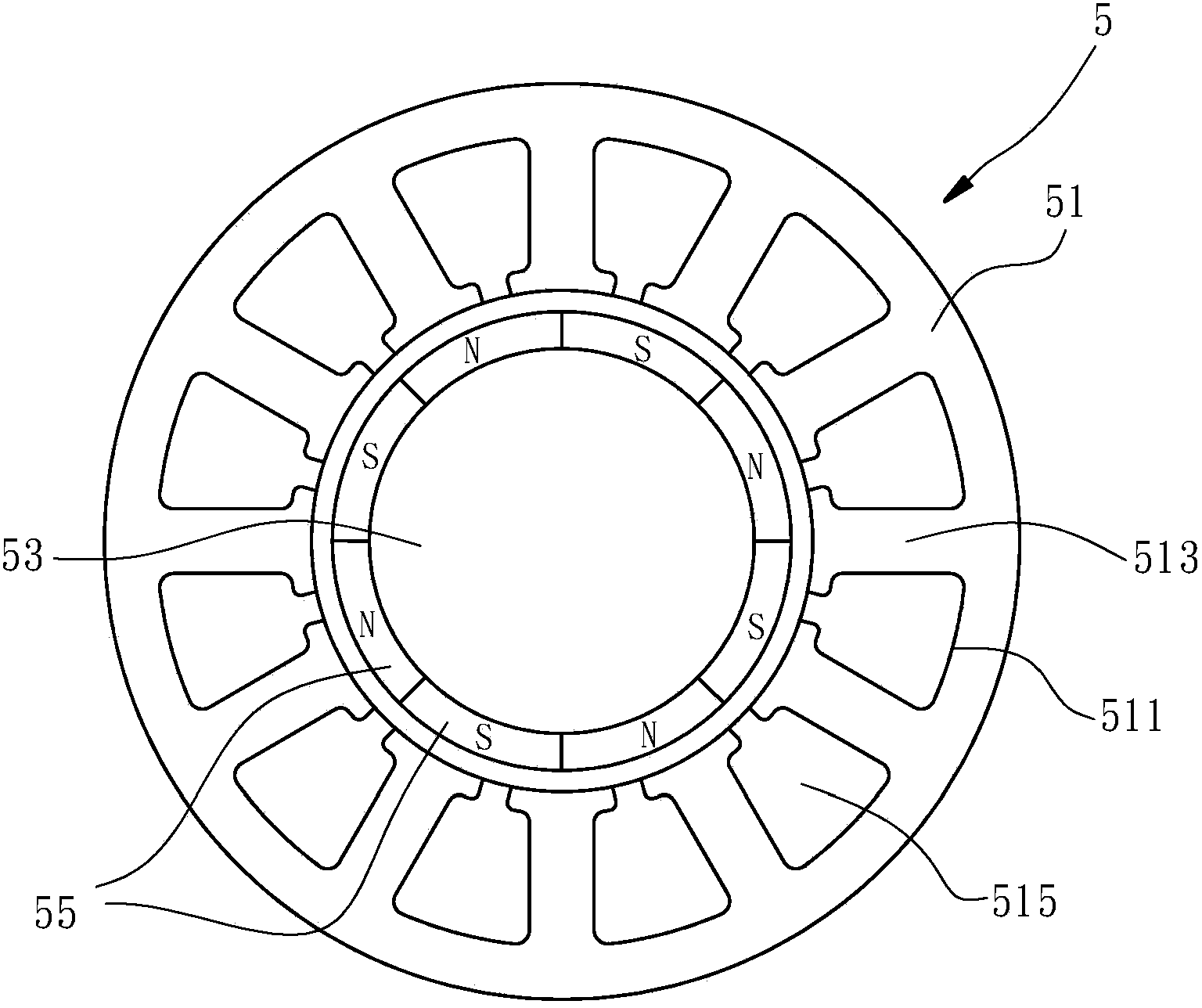

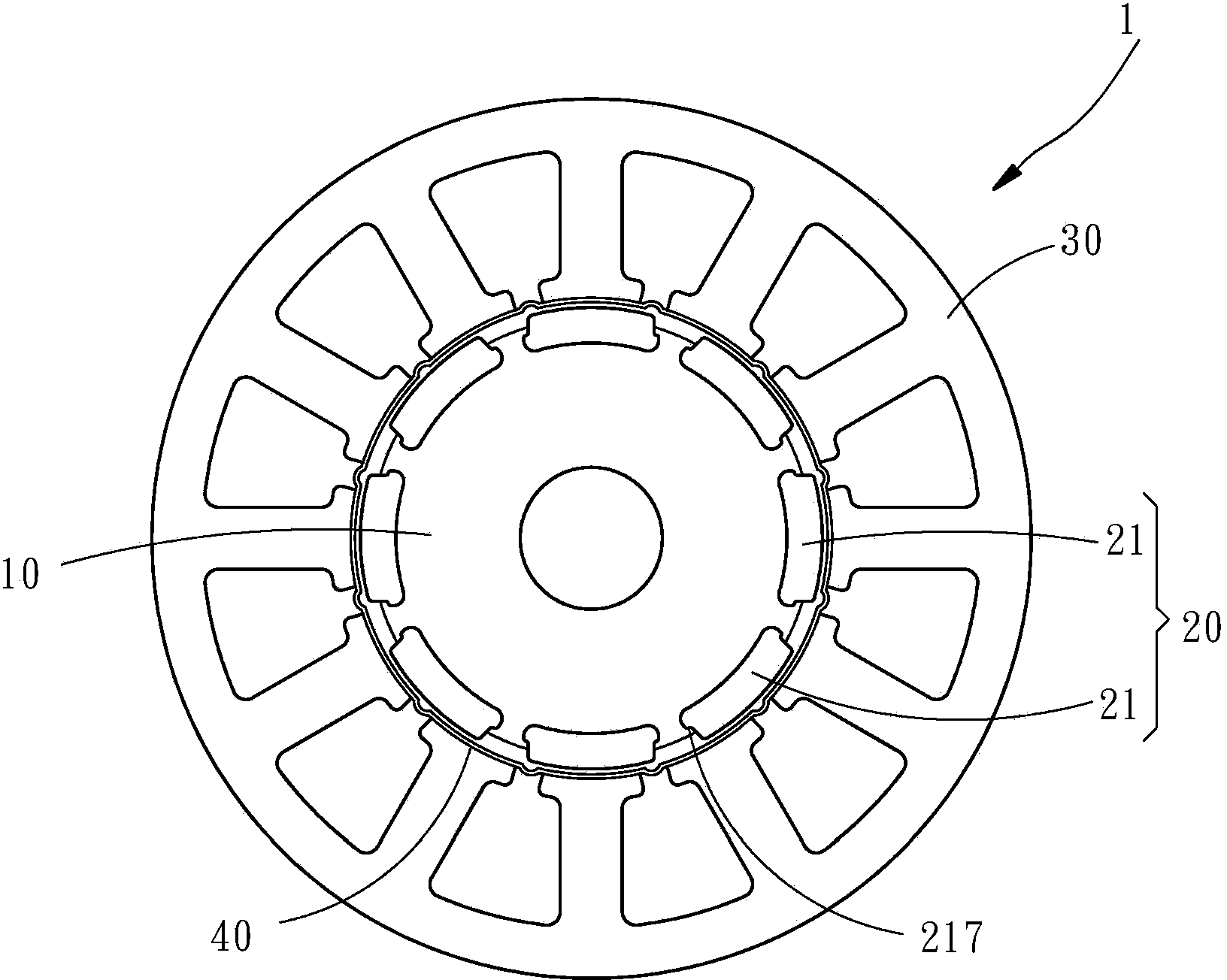

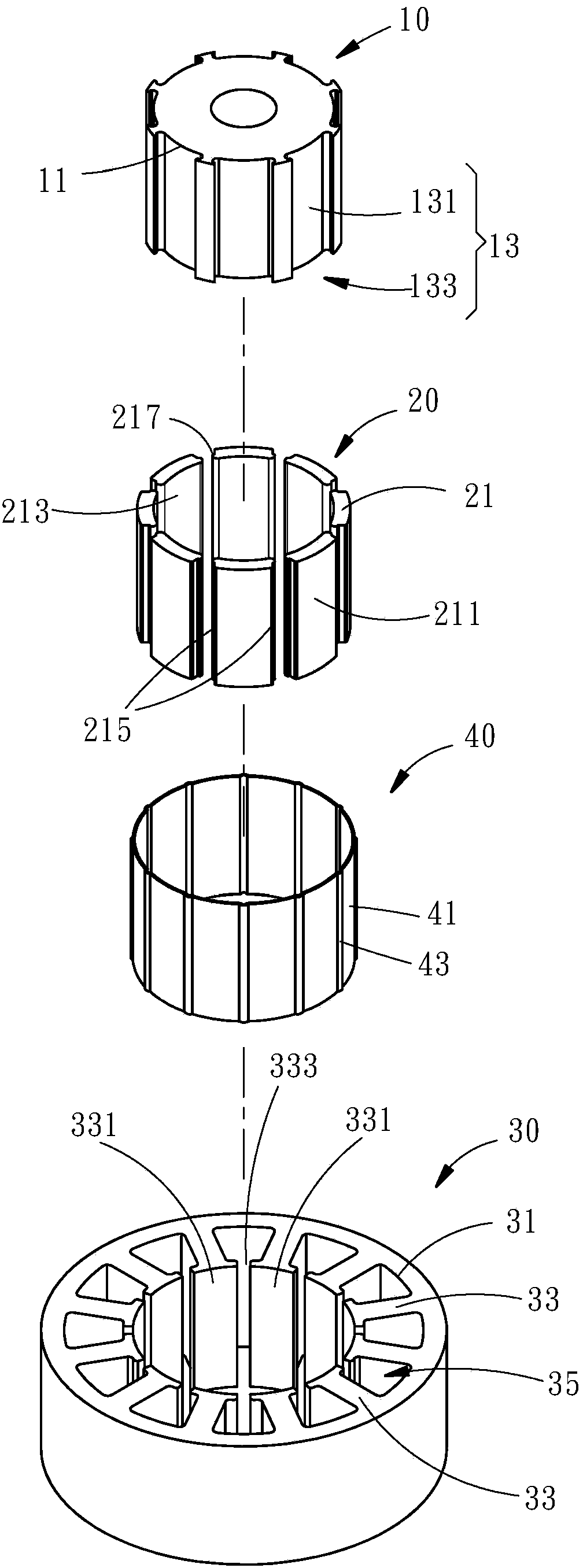

[0053] see figure 2 , image 3 and Image 6 Shown are the first and second preferred embodiments of the present invention. A brushless permanent magnet motor 1 , 2 includes a rotor 10 , a magnet assembly 20 , a stator 30 , and a sleeve 40 .

[0054]The rotor 10 includes an outer peripheral surface 11 and a plurality of slots 13 disposed along the outer peripheral surface 11 , and each of the slots 13 has a first accommodating space 131 sequentially from the rotor 10 toward the stator 30 And a second accommodating space 133 , the volume of the first accommodating space 131 is larger than that of the second accommodating space 133 .

[0055] The magnet group 20 is composed of a plurality of magnet units 21, each of the magnet units 21 has an outer arc surface 211, an inner arc surface 213 and two side surfaces 215, wherein each of the side surfaces 215 is adjacent to the inner arc surface 213 A flange 217 is provided for each of the magnet units 21 to be firmly embedded in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com