Multilayer circuit board and manufacturing method thereof

A technology of multilayer circuit board and manufacturing method, which is applied in the direction of multilayer circuit manufacturing, printed circuit manufacturing, printed circuit, etc., can solve the problems of unfavorable process simplification, high production cost, and many pressing times, so as to save raw materials, Improved yield rate and easy repair

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

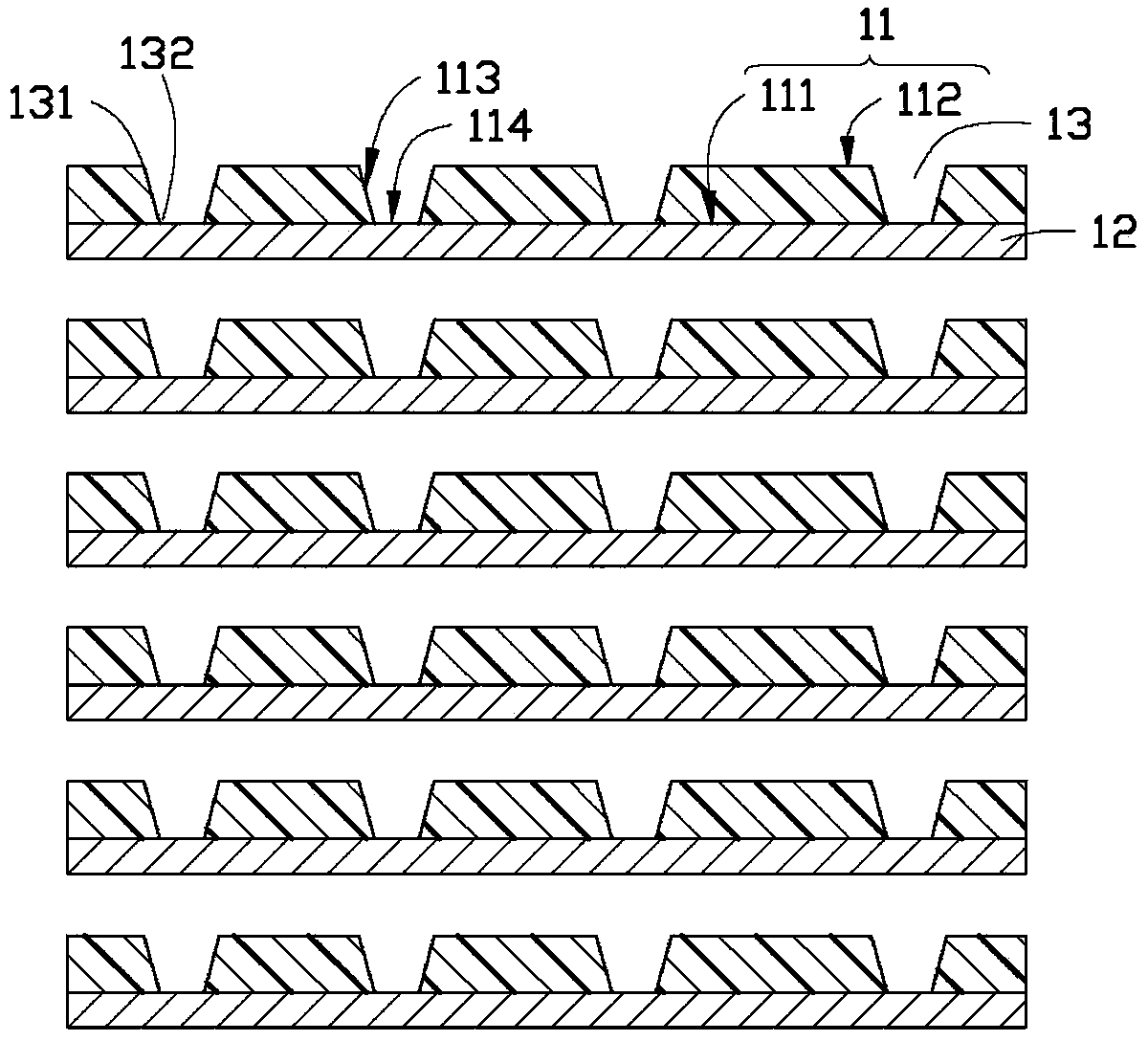

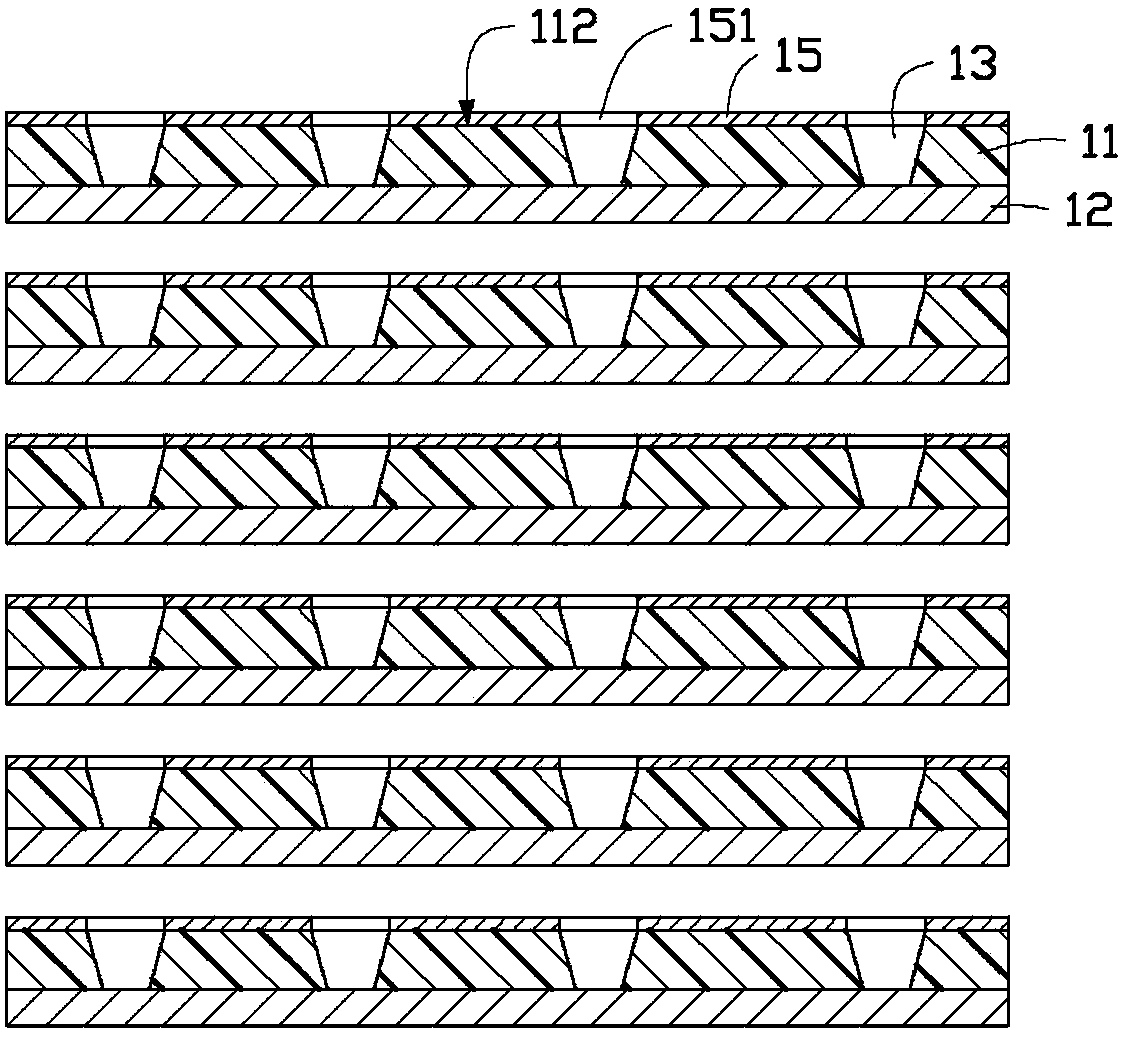

[0020] The multi-layer circuit board and the manufacturing method thereof provided by the technical solution will be further described in detail below with reference to the accompanying drawings and embodiments.

[0021] The manufacturing method of the multilayer circuit board provided by the embodiment of this technical solution includes the following steps:

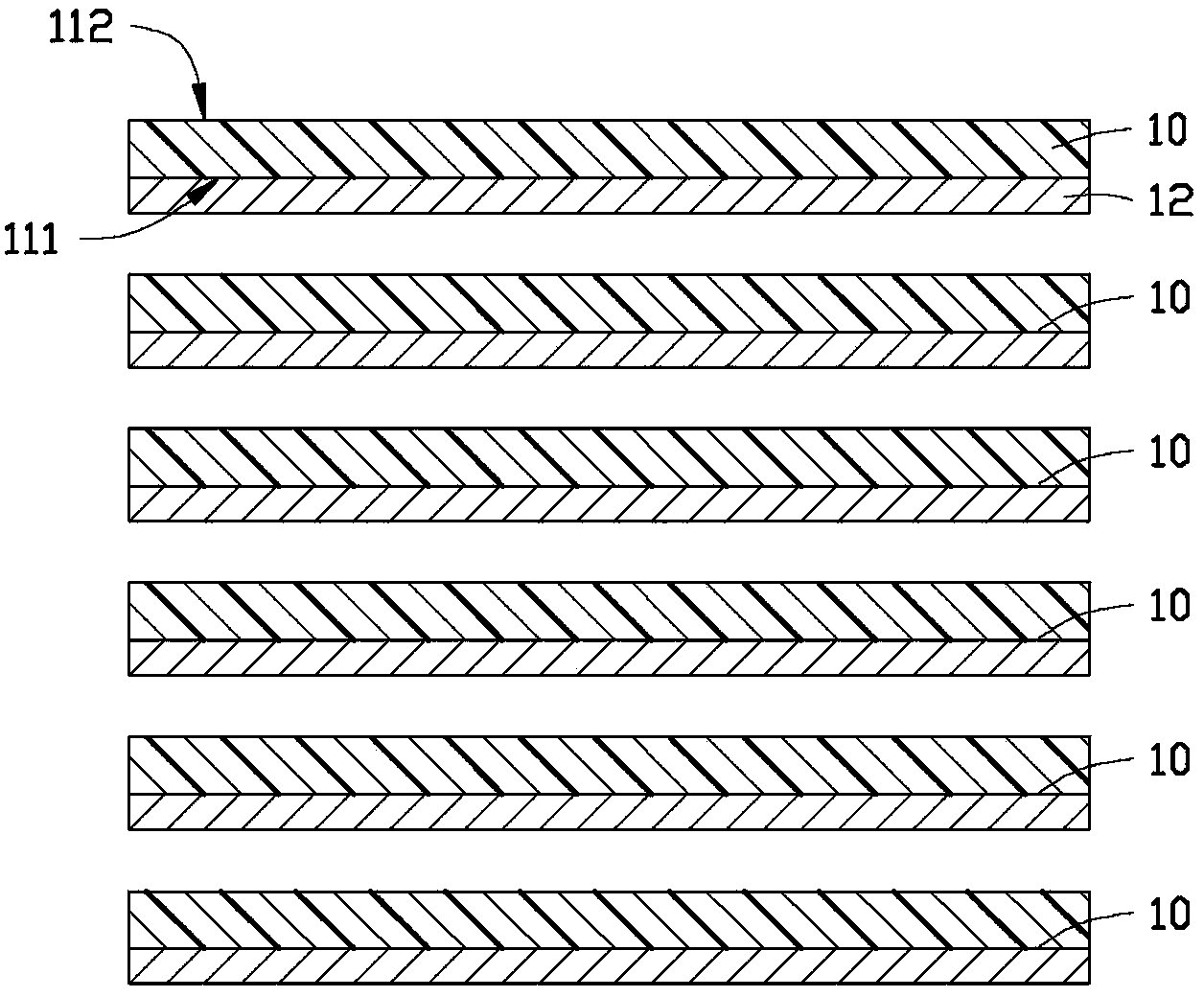

[0022] As a first step, see figure 1 , and N copper clad substrates 10 are provided. Among them, N is a natural number greater than or equal to 3. Each copper clad substrate 10 includes an insulating layer 11 and a copper foil layer 12 bonded to one side of the insulating layer 11 .

[0023] The insulating layer 11 includes a first surface 111 adhering to the copper foil layer 12 and a second surface 112 opposite to the first surface 111 . The insulating layer 11 is a thermoplastic resin, preferably a thermotropic liquid crystal polymer (LCP) with low water absorption, low thermal expansion coefficient, high heat res...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap