A liquid-cooled heat dissipation cold plate

A liquid-cooled heat dissipation, cold plate technology, applied in cooling/ventilation/heating transformation, etc., can solve the problems of inability to meet the requirements of heat dissipation, equipment damage, direct contact, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

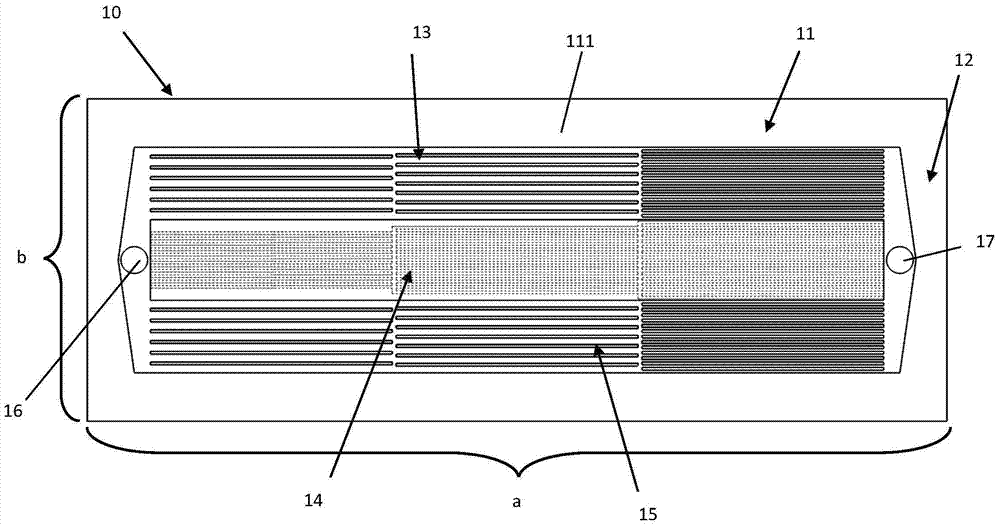

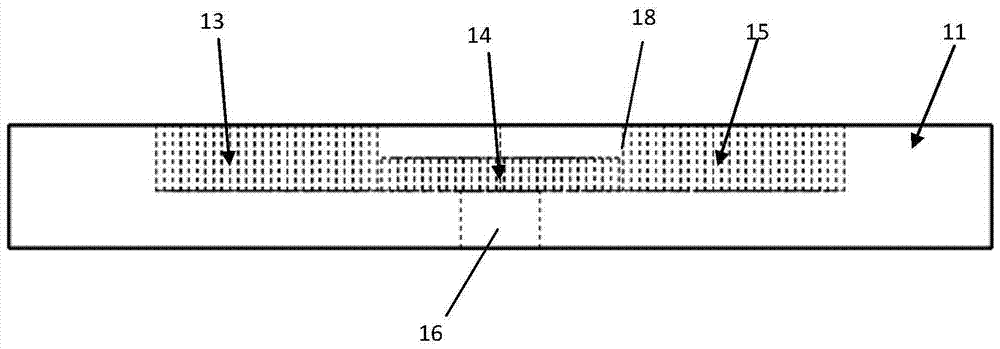

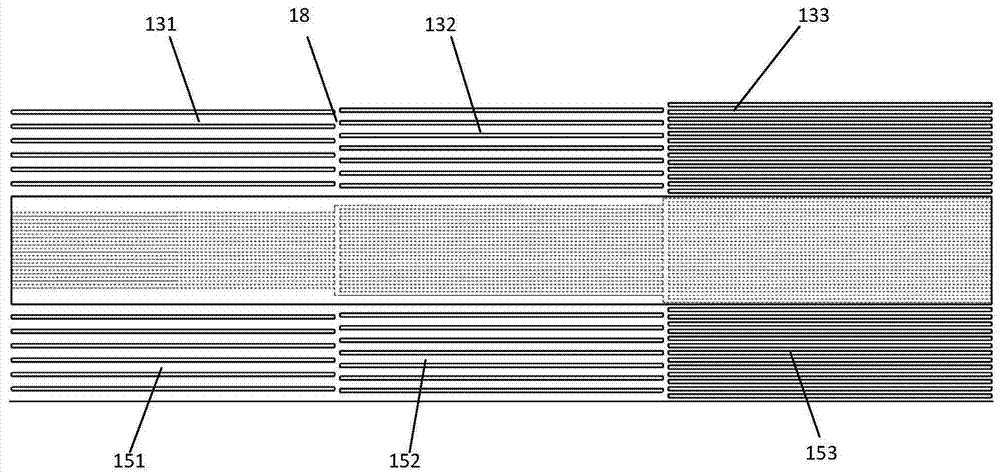

[0022] The specific implementation forms of the liquid-cooled and heat-dissipating cold plate involved in the present invention will be further described below in conjunction with the accompanying drawings.

[0023]

[0024] like figure 1 , as shown in 2, 3, and 4, the liquid-cooled heat dissipation cold plate 10 provided by this embodiment is used to cool down electronic equipment, and is made of aluminum material, including a bottom plate 11, a cooling part 12, and a cooling part 12 above the figure. cover plate.

[0025] The bottom plate 11 has a thickness of 4 mm and includes a cooling plate surface 111 and a bottom surface opposite to the cooling plate surface 111 .

[0026] The cooling part 12 is disposed on the cooling plate surface 111 and includes a first channel area 13 , a second channel area 14 , a third channel area 14 , a water inlet 16 , and a water outlet 17 .

[0027] The first flow channel area 13, the second flow channel area 14, and the third flow chann...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com