Method and device for changing the formation of a paper web

A paper format and paper machine technology, applied in the direction of paper making, paper machine, paper machine wet end, etc., can solve problems such as impact, and achieve the effect of less production process, optimized production process, and good quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

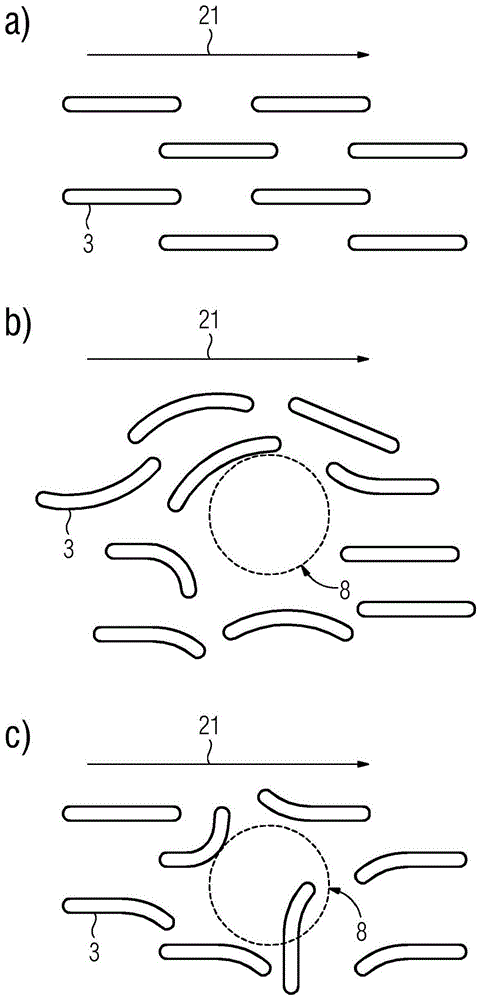

[0033] figure 1 Include sub figure 1 a to 1c, which show the entire sequence of fiber orientations, are enlarged top views of a fiber layer of a still wet paper web being formed. This sequence illustrates the variation of the orientation of the fibers 3 in the paper web as it passes through the device for varying the formation of the paper fibers in the paper web.

[0034] figure 1 a shows an initial state in which the main orientation of the paper fibers 3 in the fiber layer being formed is along the direction of movement 21 of the screen. This initial state of markedly anisotropic fiber orientation is usually due to the layout and high screen speeds of the screens in industrial paper machines. The original orientation of the fibers 3 is along the screen movement direction 21 , as it is given by the fiber material coiled up on the screen moving in the screen movement direction 21 .

[0035] figure 1 b shows the state formed just after discharge along the discharge channe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com