Electric manipulator for wolfberry picking

An electric manipulator and goji berry technology, which is applied to picking machines, agricultural machinery and implements, harvesters, etc., can solve the problems of low picking efficiency, fruit crushing, failure to promote, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

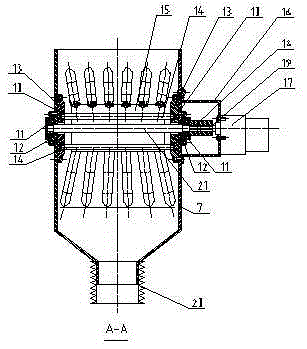

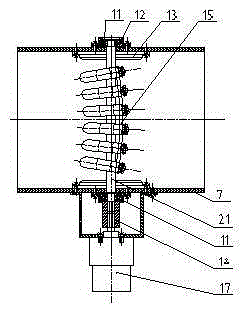

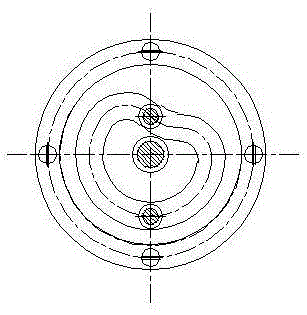

[0019] combine figure 1 , 2 , 3, 4, and 5 describe a specific embodiment of the present invention in detail, but do not limit the claims of the present invention in any way.

[0020] The wolfberry picking electric manipulator of the present invention comprises a rotating shaft 21, and is characterized in that several arc plates 15 are evenly fixed on the rotating shaft 21, and the other end of each arc plate 15 is tangentially installed with several mechanical fingers through the hinge shaft 4, A thumb crest is installed relative to each group of mechanical fingers; there is a roller 14 parallel to the rotating shaft on the radial straight edge of the arc plate 15, and the roller 14 can move radially along the straight edge of the arc plate 15. Two bearings 10 are contained in the chute of the cam 13; the two ends of the rotating shaft 21 have bearings 11 and bearing blocks 12 connected with the casing 7, and one end of the rotating shaft 21 is connected with the motor 17 thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com