Feedforward control method for edge drop of head part and tail part of strip steel

A feedforward control and edge drop technology, which is used in rolling mill control devices, metal rolling, manufacturing tools, etc., can solve problems such as poor control effect of the head and tail sections of the strip, fluctuations in the edge drop of hot rolling incoming materials, and incompatibility. , to achieve the effect of accurate movement value, guaranteed realization, and accurate control of target positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The feedforward control method for edge drop at the head and tail of the strip according to the present invention will be further described in detail in conjunction with specific embodiments below.

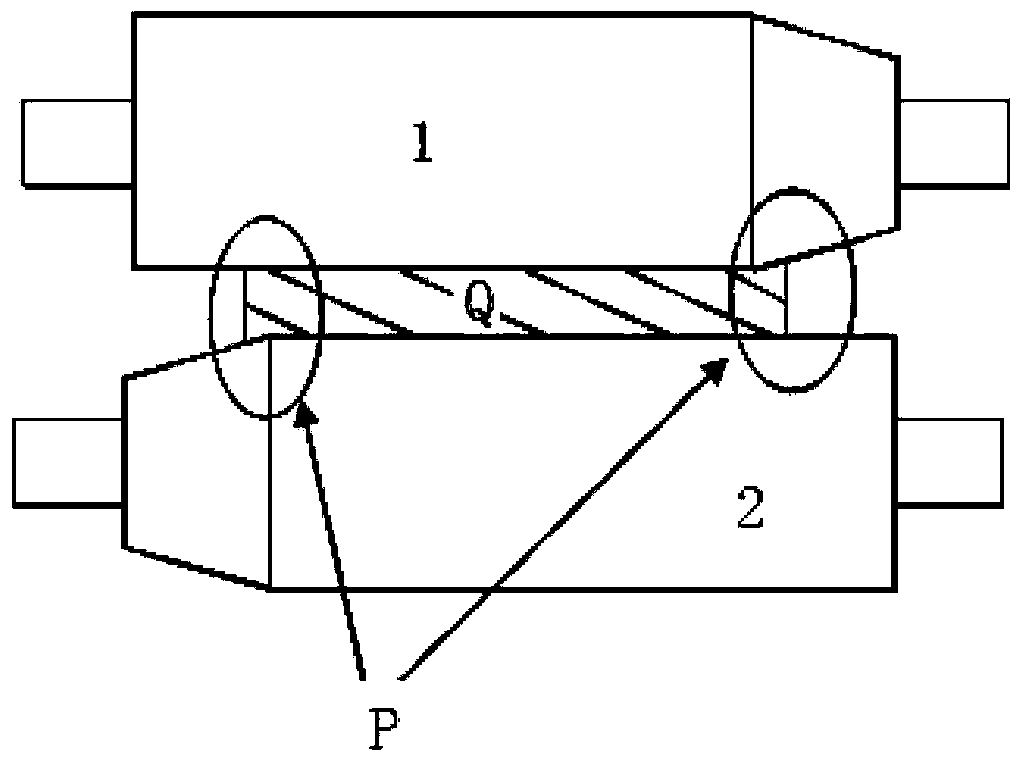

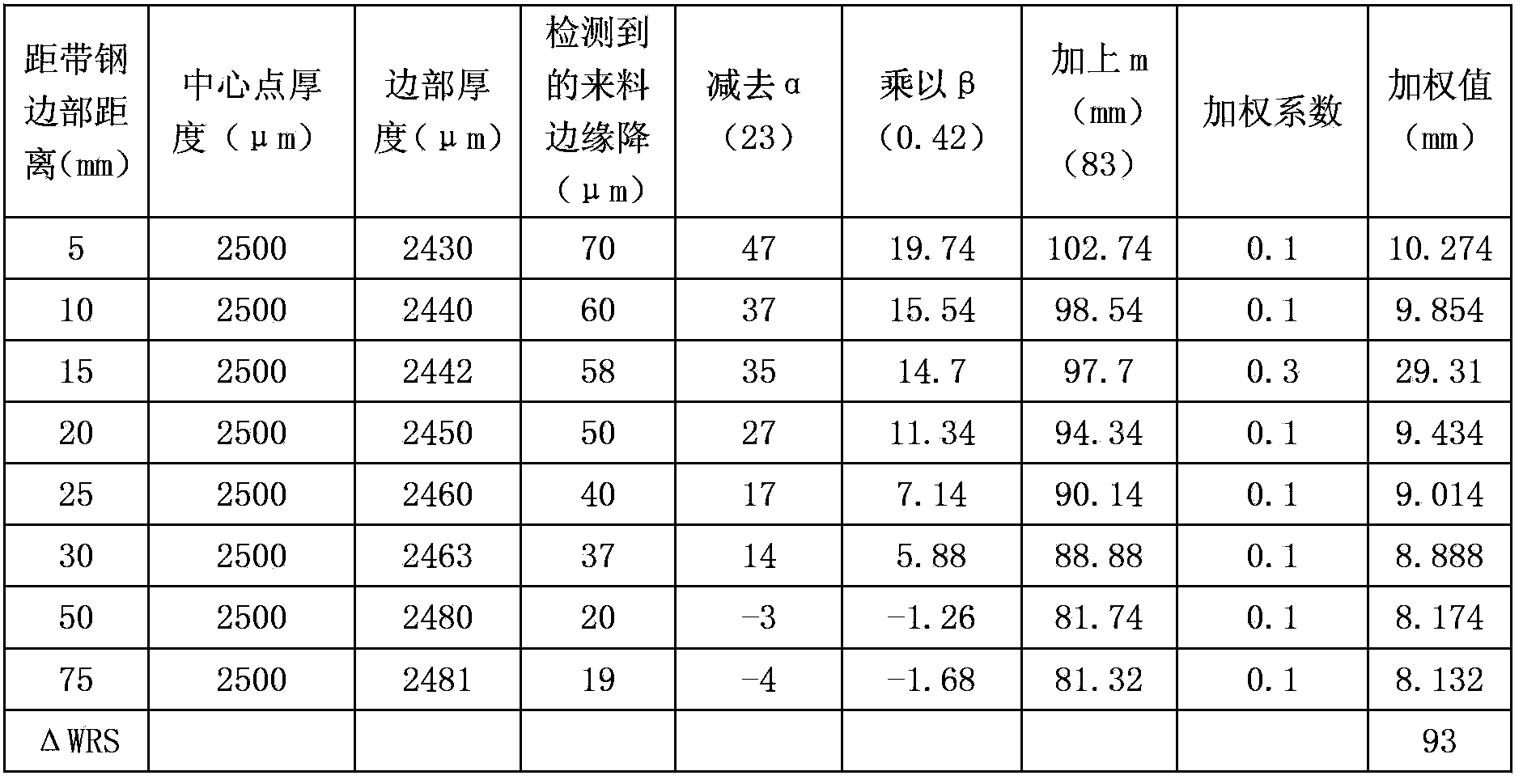

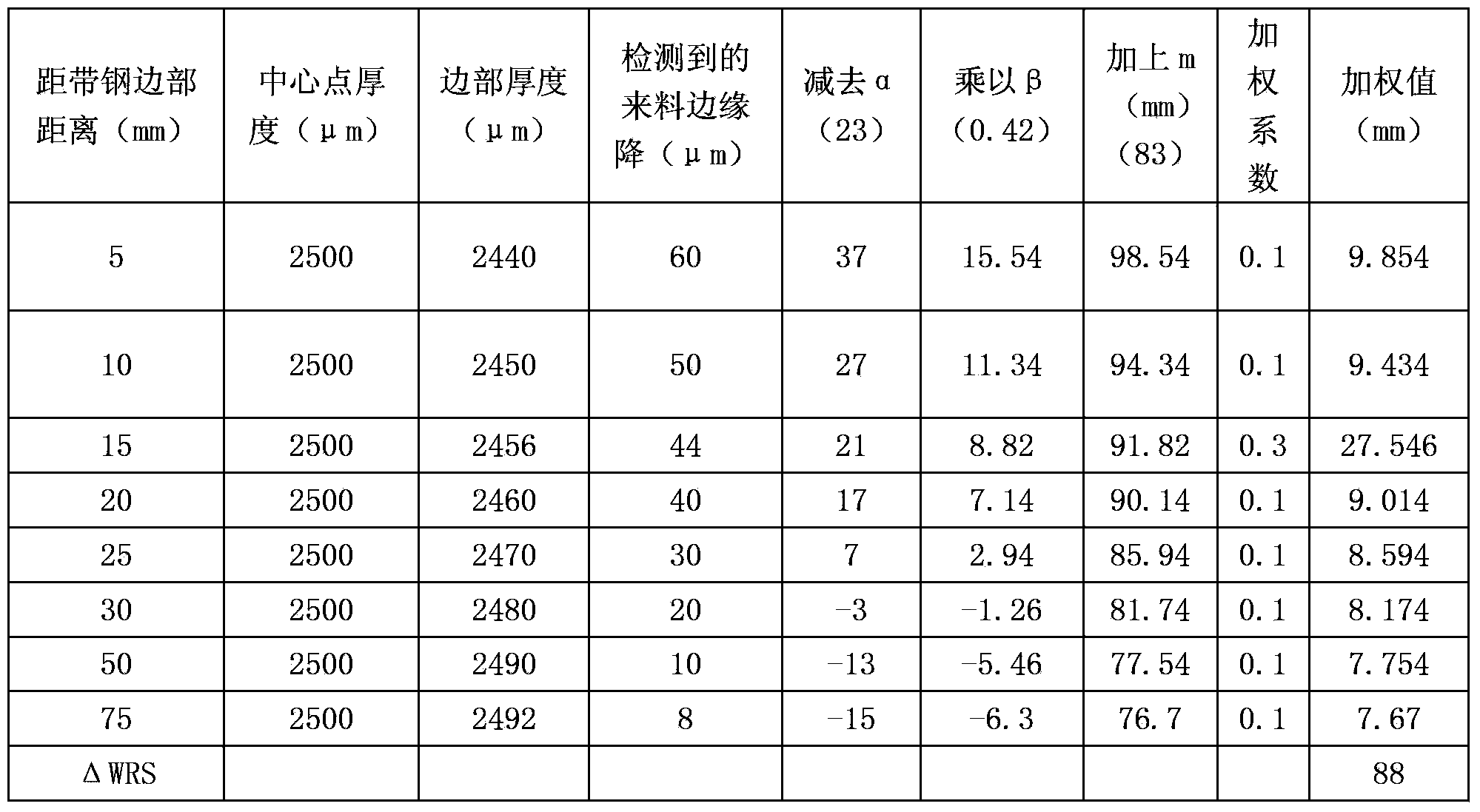

[0030] In this embodiment, the 5-stand tandem cold rolling mill cold-rolls the strip, and the previous process of cold rolling is hot rolling, so the incoming strip is a hot-rolled strip, and the center point thickness of the hot-rolled incoming strip is The thickness of the cold-rolled strip is 2.5mm, the thickness of the cold-rolled exit is 0.5mm, and the control target is that the edge drop requirement of the cold-rolled strip (15mm from the edge) is 5μm.

[0031] Strip steel head length is 15m among the present embodiment, and this 15m long strip steel is divided into equal 12 sections, every section 2.5m; For each section, all carry out following steps:

[0032] (1) Take 8 points from the edge of the strip to the center in the width direction of the strip. These 8 poin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com