A 12/6-pole hybrid rotor structure magnetic levitation switched reluctance generator and its control method

A switched reluctance, hybrid rotor technology, applied in synchronous generators and other directions, can solve the problems of the output power density to be improved, the mechanical energy conversion efficiency is low, etc., and achieve high utilization efficiency, strong radial load capacity, and small radial force fluctuations. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The specific implementation manner of the present invention will be further described below in conjunction with the accompanying drawings.

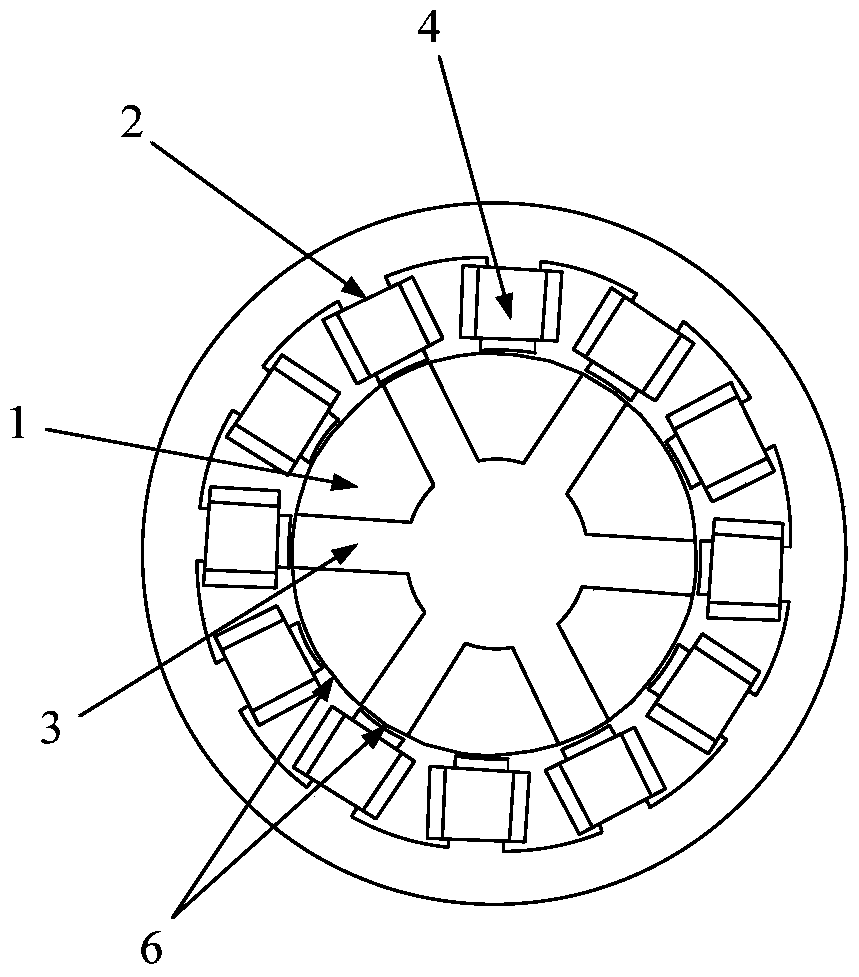

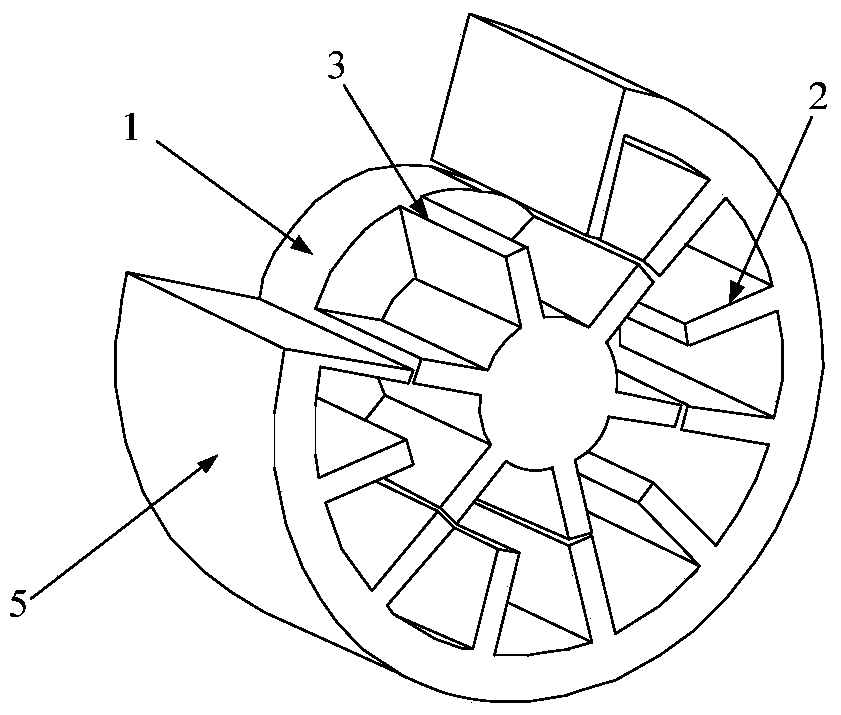

[0029] Such as figure 1 , 2 As shown, the mixed rotor structure magnetic levitation switched reluctance generator of the present invention, the motor core is composed of a salient pole stator, a salient pole rotor and a disc shaft hybrid structure; including a disc 1, a stator salient pole 2, a rotor salient pole 3, Winding 4, stator core 5, air gap 6. The rotor is composed of a disk 1 and a rotor salient pole 3 axially superimposed; the disk 1 provides radial force, and the rotor salient pole 3 provides braking negative torque.

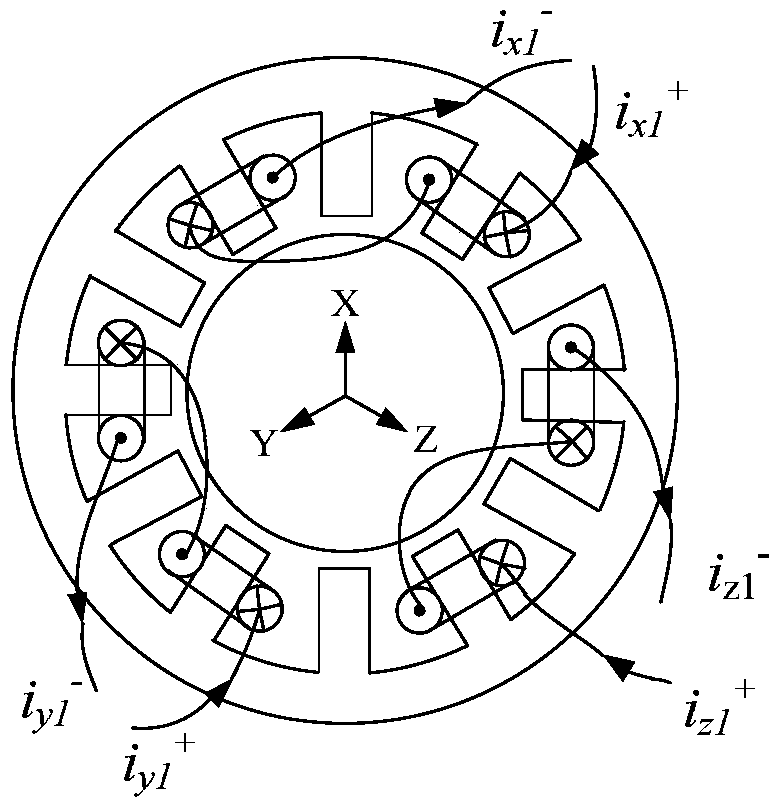

[0030] The hybrid rotor structure magnetic levitation switched reluctance generator of the present invention has 12 salient teeth of the stator and 6 rotor salient teeth of the hybrid structure, and each phase winding is composed of two windings 4 connected in series with an interval of 60°, and each ph...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com