A Feedwater Control Method to Suppress Main Steam Pressure Rise in FCB Process

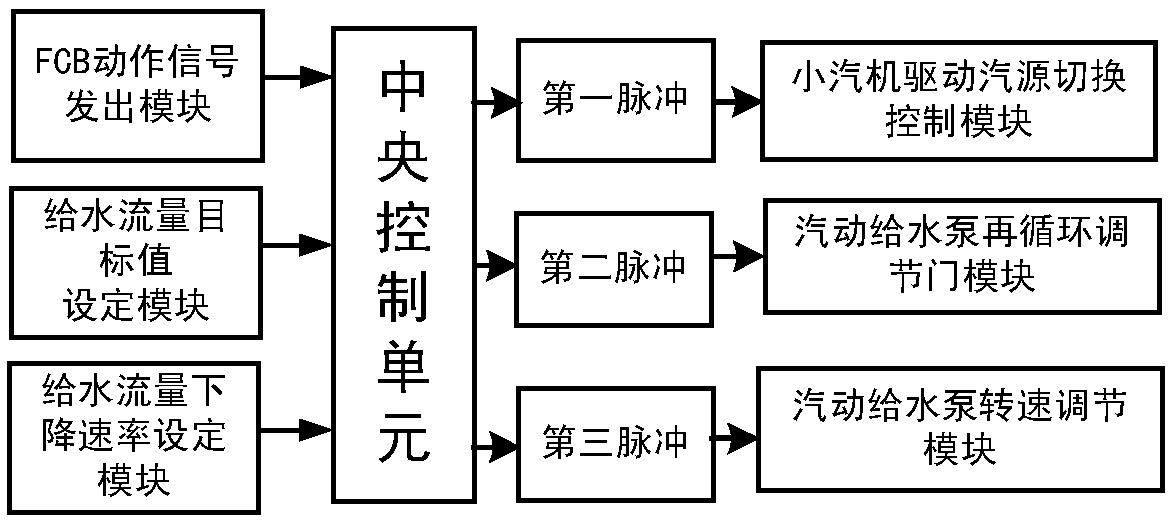

A control method and technology of main steam pressure, applied in the direction of controlling water supply, steam generation, lighting and heating equipment, etc., can solve the problems of large equipment renovation costs and equipment installation costs, equipment ordering and equipment commissioning cycle, difficult implementation of active units, etc. , to avoid mutual interference problems, reduce the range of rapid rise, and improve the success rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

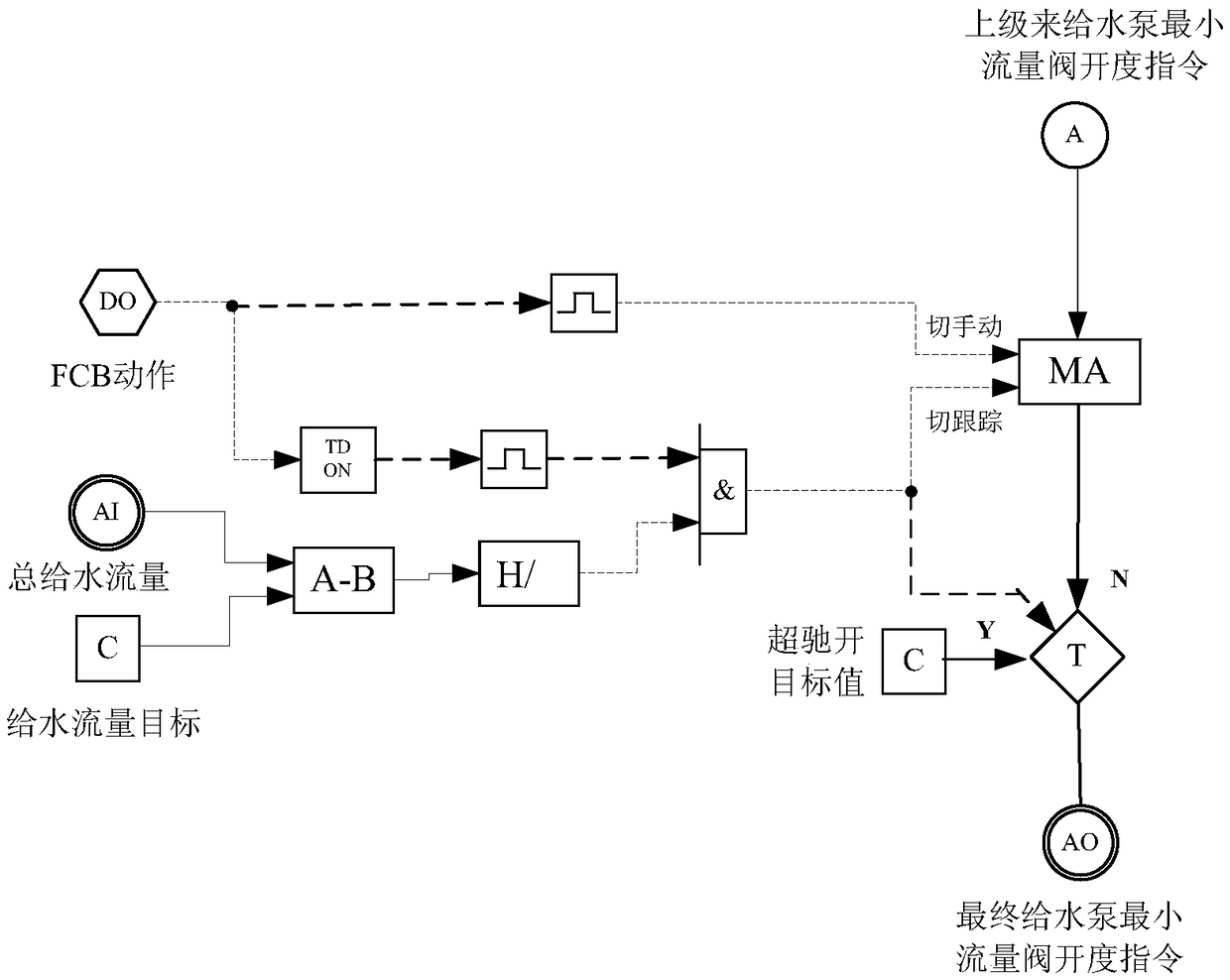

[0044] Embodiment 1: Taking a 660MW supercritical unit as an example, after the central control unit detects the action of the FCB, the first feedwater pump quickly reduces the output and the second feedwater pump controls the total feedwater flow.

[0045] Step S101: the central control unit detects the FCB action signal sent by the FCB action signal sending module;

[0046] Step S102: After the central control unit detects the action of the FCB, switch the steam source driven by the steam-driven feedwater pump, and immediately interlock and open the electric door and the regulating door of the steam pipeline from the cold section of the unit reheating steam to the small steam turbine, and the regulating door is quickly opened to a certain opening degree (e.g. 60%) and put into automatic operation; at the same time, close the steam extraction check door and electric door of the fourth stage of the steam turbine to the small steam turbine and deaerator to prevent the steam in t...

Embodiment 2

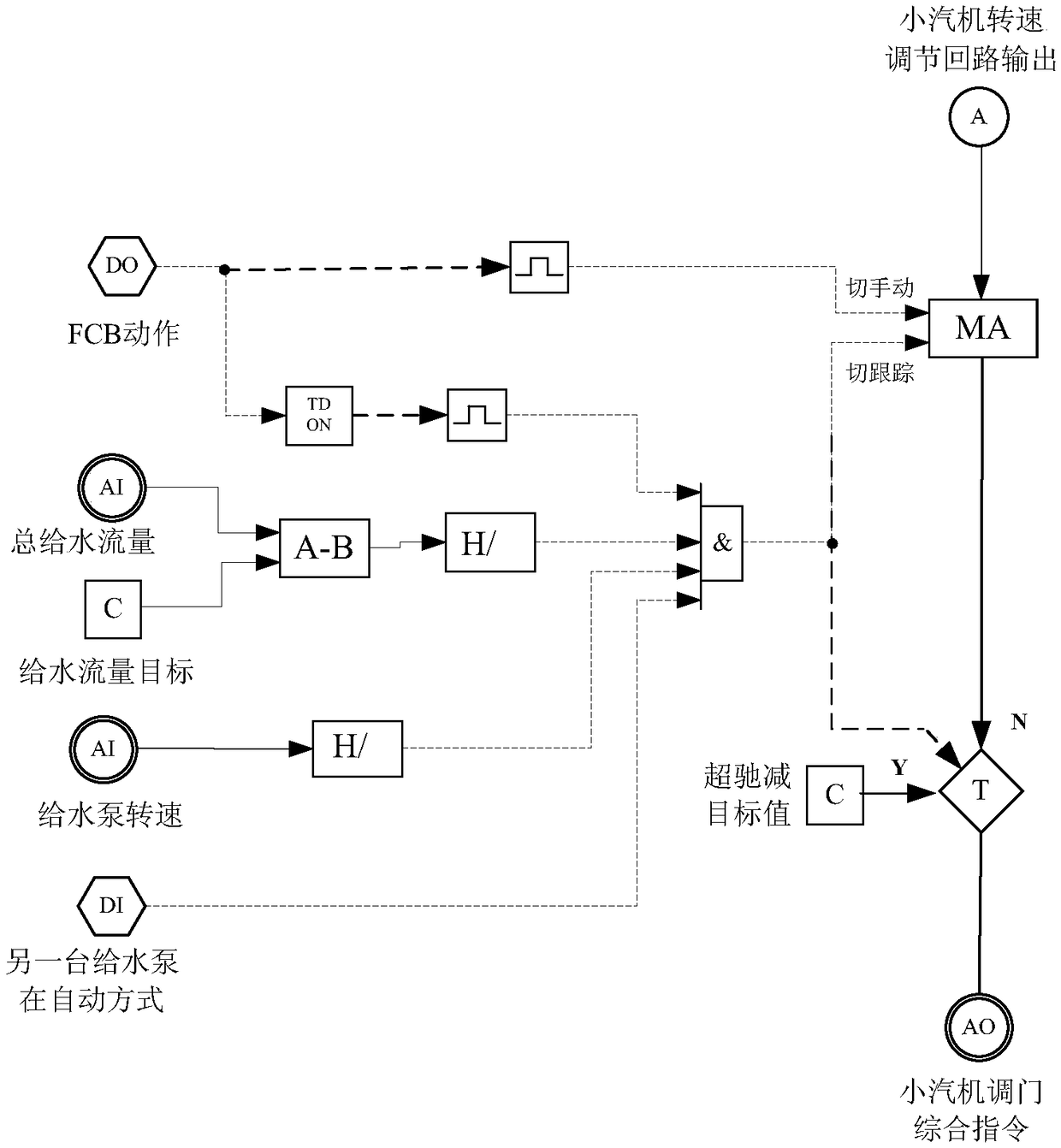

[0050] Embodiment 2: Taking a 660MW supercritical unit as an example, after the central control unit detects the action of the FCB, two feedwater pumps are paralleled to control the total feedwater flow at the same time.

[0051] It includes steps:

[0052] Step S201: the central control unit detects the FCB action signal sent by the FCB action signal sending module;

[0053] Step S202: After the central control unit detects the action of the FCB, switch the steam source driven by the steam-driven feedwater pump, and immediately interlock and open the electric door and the regulating door of the steam pipeline from the cold section of the unit reheating steam to the small steam turbine, and the regulating door is quickly opened to a certain opening degree (e.g. 60%) and put into automatic operation; at the same time, close the steam extraction check door and electric door of the fourth stage of the steam turbine to the small steam turbine and deaerator to prevent the steam in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com