Control method of coiling tension of oriented silicon steel continuous annealing unit

A technology of coiling tension and continuous withdrawal unit, which is used in rolling mill control devices, metal rolling, metal rolling, etc., can solve the problems of poor shape of incoming material and no clear control method for edge cracks of strip steel.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

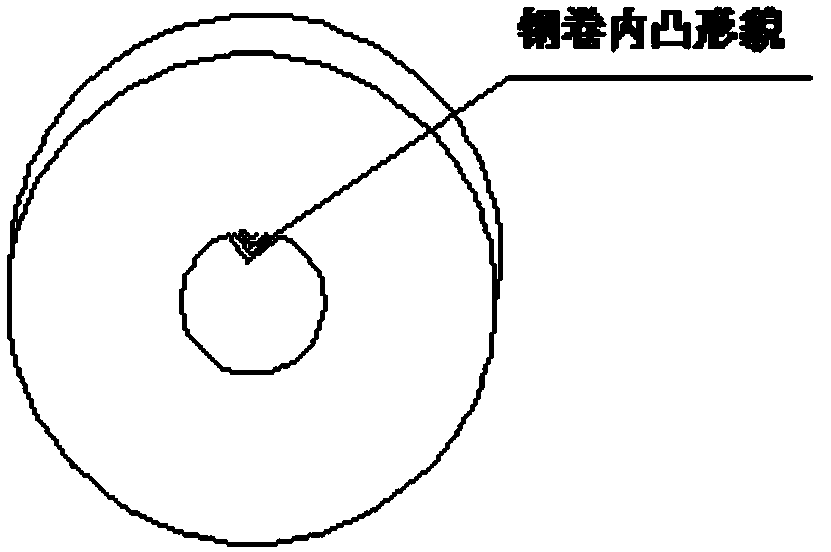

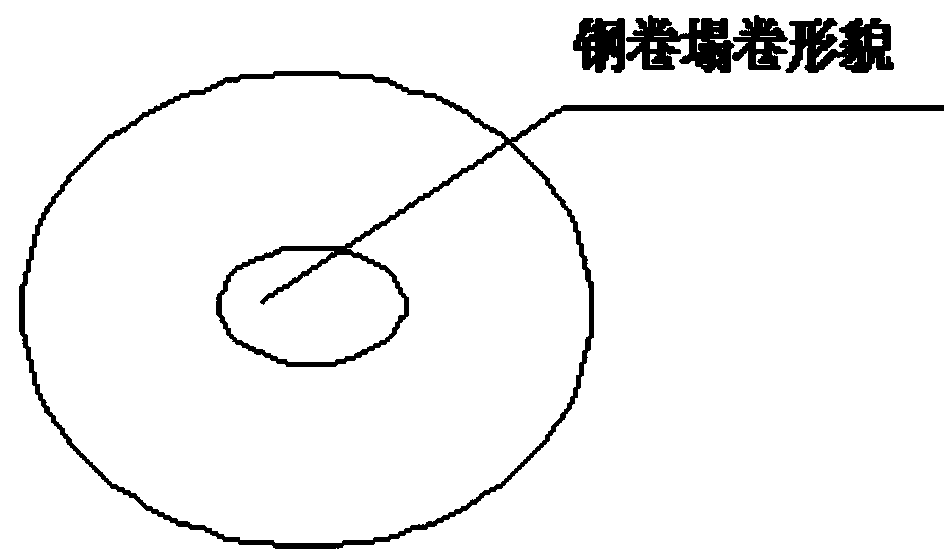

[0112] In the coiling process, in order to avoid the edge bursting of the strip, and also to avoid the tower shape caused by the poor shape of the edge, a quantitative amount of misalignment and a fixed misalignment period are used for coiling. The control reference is :

[0113] Misalignment depth is 15mm--20mm

[0114] Misalignment period is 20mm--30mm

[0115] In the present invention, the amount of misalignment adopted is the coiling control mode of edge centering; the misalignment cycle is controlled by the coiling thickness, and this method is not affected by the thickness of the steel strip.

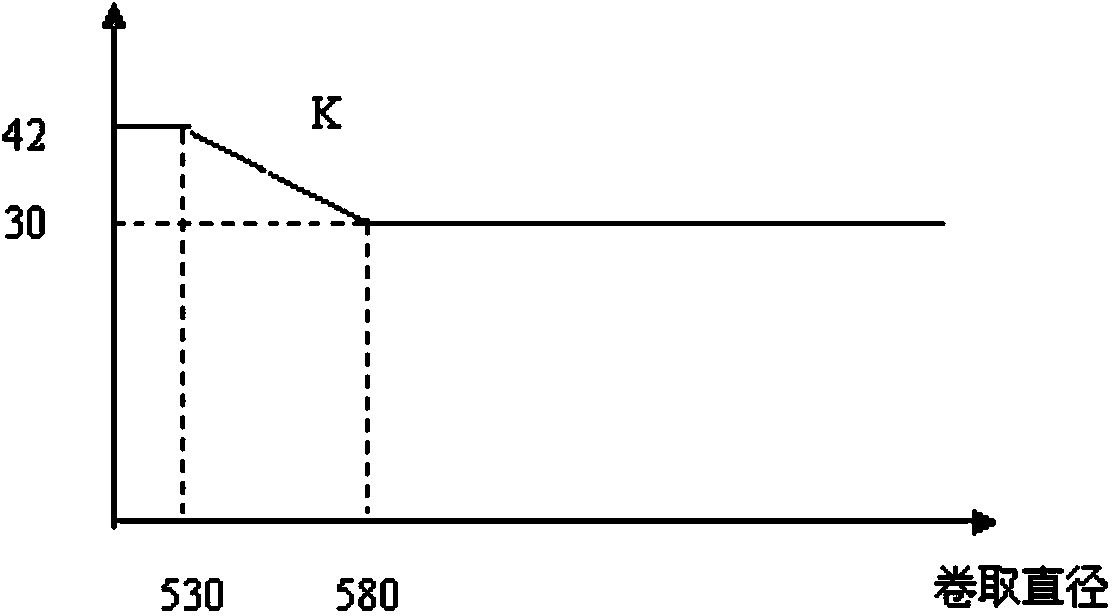

[0116] The stated tension is the unit tension of the cross-section of the steel strip. The setting process is based on N / mm2. Through program control, this unit tension mode control can avoid tension errors caused by differences in product thickness and width.

[0117] The tension drop slope between the two platforms is calculated as the ratio of the tension difference between t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com