Screen printing plate

A screen and net knot technology, applied in printing, printing presses, rotary printing machines, etc., can solve the problems of inability to meet the needs of screen printing, restricting the applicable conditions of screen printing, and single mesh structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

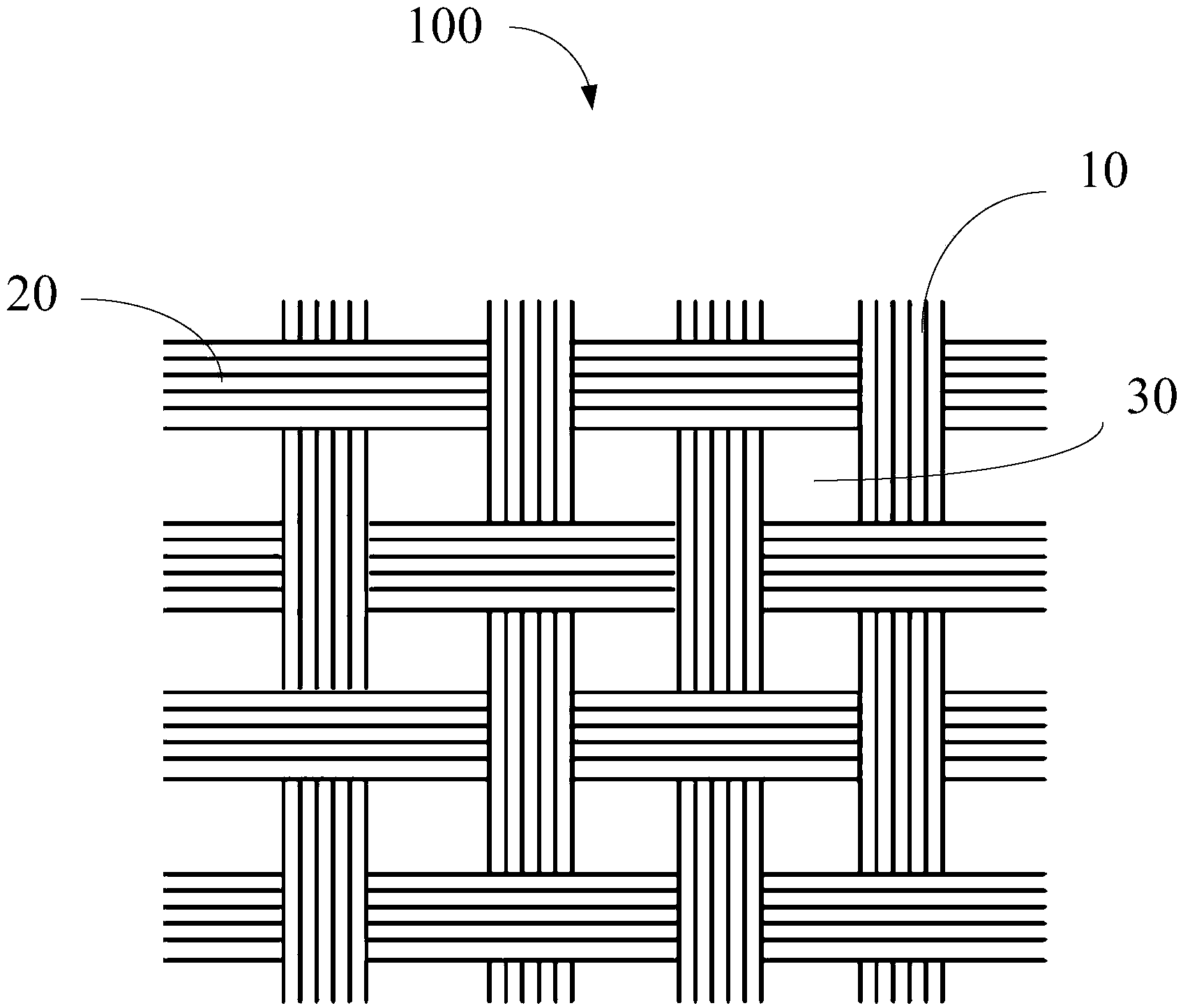

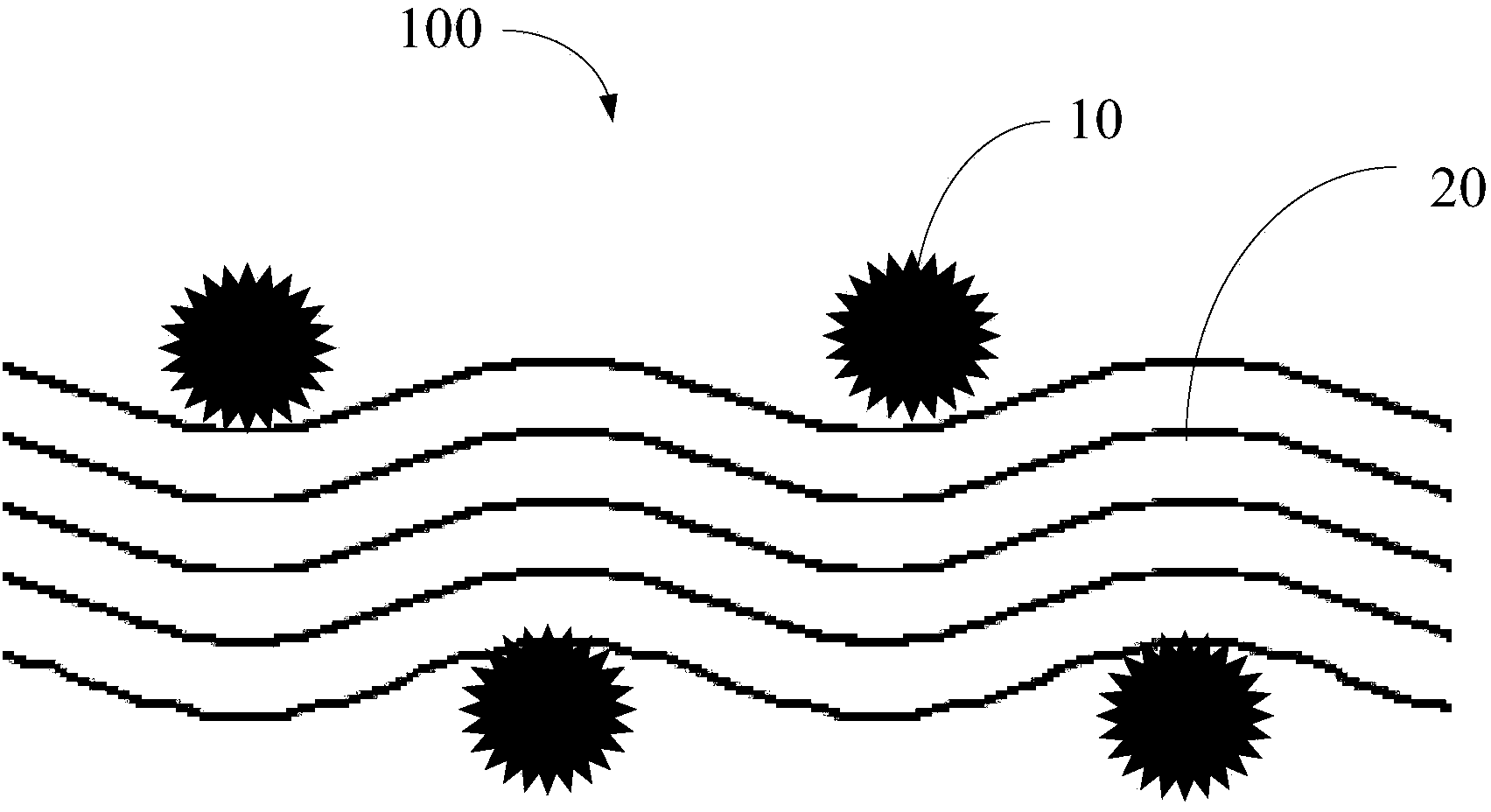

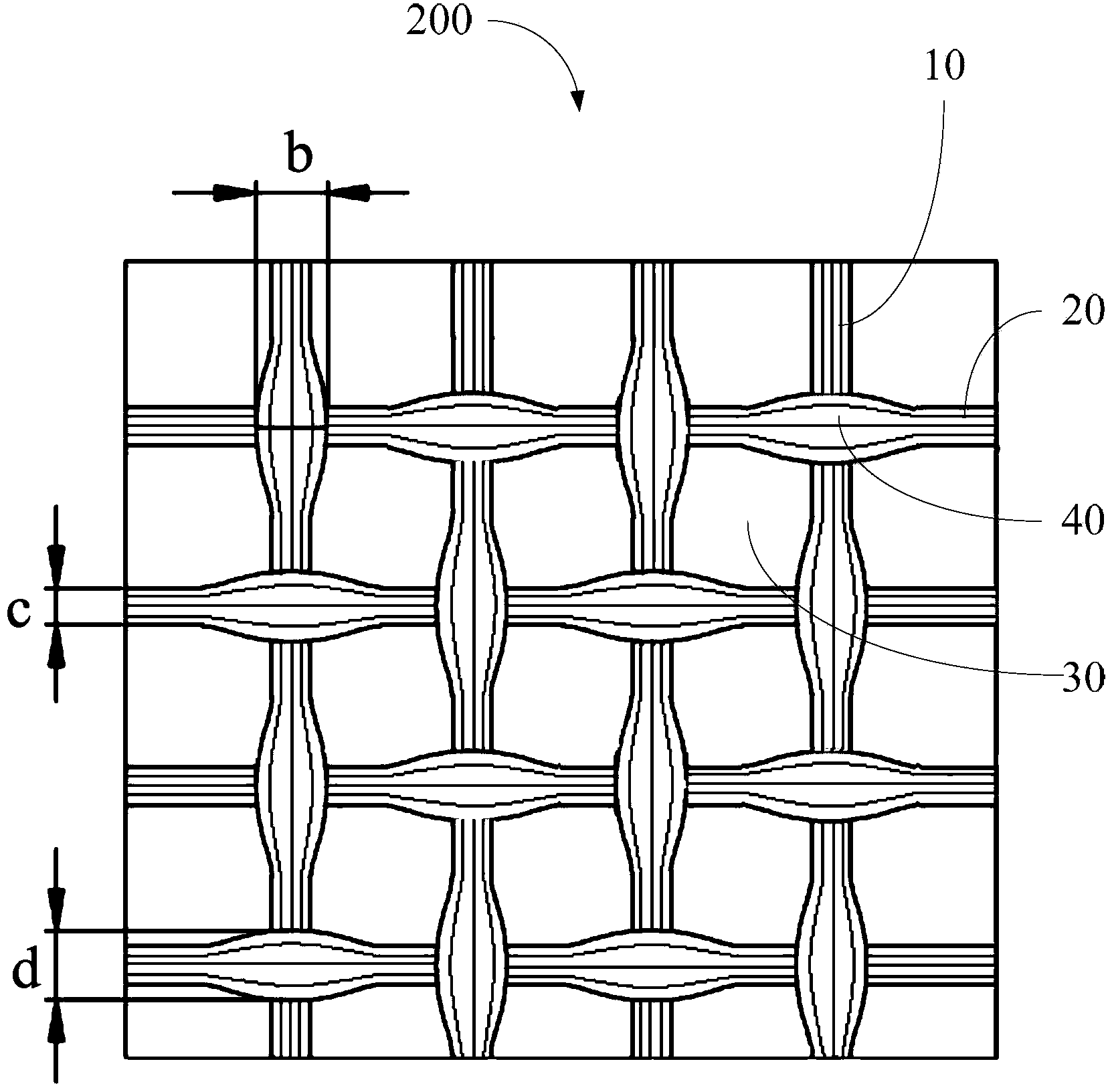

[0022] see figure 1 and figure 2 , a preferred embodiment of the present invention provides a printing screen 100 . The printing screen includes a plurality of warp threads 10 and a plurality of weft threads 20 . The warp yarns 10 and the weft yarns 20 are woven in a vertically interlaced manner to form a plurality of openings 30 . Surfaces of the warp threads 10 and / or the weft threads 20 are uneven.

[0023] In this embodiment, since the surface of the warp thread 10 and / or the weft thread 20 is uneven, when using the printing screen plate 100 for screen printing, when the paste is poured through the opening 30, the paste will The contact area between the material and the warp threads 10 and weft threads 20 around the opening 30 increases. According to the characterist...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com