Honeycombed steel box concrete wallboard module, manufacturing method thereof and wall body

A technology of steel box concrete and concrete, which is applied to walls, building components, buildings, etc., can solve the problems that the performance reliability cannot be demonstrated, and the joint structure of the modules has not been explained in detail, such as fire resistance and riot resistance, and the joints are simple and reliable, and the rigidity is large. , good waterproof performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

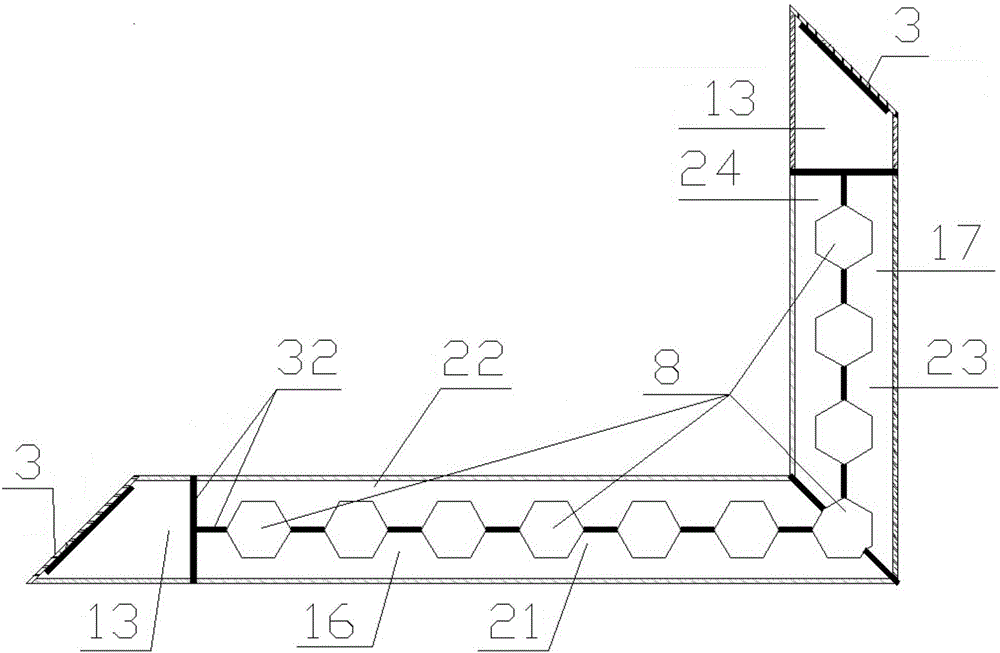

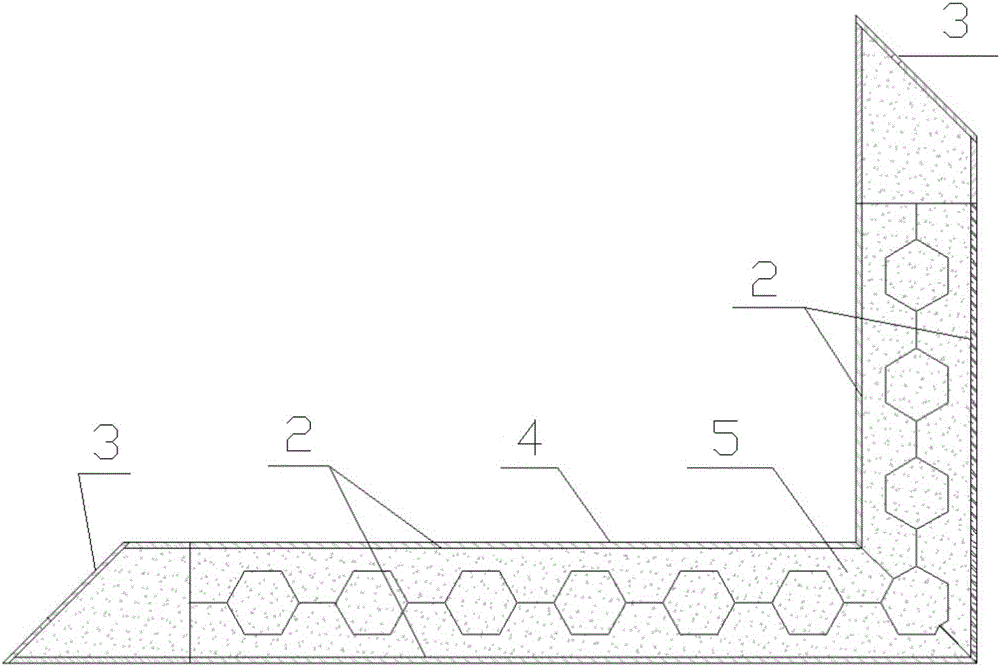

[0070] The first embodiment is: the oblique end plates 3 are patterned steel plates, the outer surface of the oblique end plate 3 at one end of the steel box 4 has a raised pattern, and the outer surface of the oblique end plate 3 at the other end has a concave pattern, and the outer surface of the oblique end plate 3 has a raised pattern. The pattern matches the shape and specification of the debossed pattern. During implementation, first apply structural glue 33 in the concave pattern of the checkered steel plate at the joint, then butt the ends of the two modules so that the concave and convex parts of the checkered steel plate interface bite each other, and then perform butt welding on the adjacent steel plates on the inner and outer surfaces of the modules , so as to complete the horizontal splicing of the modules.

[0071] The second embodiment is: the outer surface of the oblique end plate 3 at one end of the steel box 4 is provided with a transverse connection shear ke...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com