Gob-side entry retaining system and method for cementing gangue in gob-side goaf into wall

A goaf and goaf retaining technology, which is applied to mining equipment, earthwork drilling, shaft lining, etc., can solve the problems of large material and labor input, irreversible deformation and damage of walls, and poor airtight effect of gobs. The effect of low labor intensity of workers, wide range of application conditions, and small amount of auxiliary transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in more detail below with reference to schematic diagrams, wherein preferred embodiments of the present invention are shown, and it should be understood that those skilled in the art can modify the present invention described herein while still achieving the advantageous effects of the present invention. Therefore, the following description should be understood as the broad knowledge of those skilled in the art, but not as a limitation of the present invention.

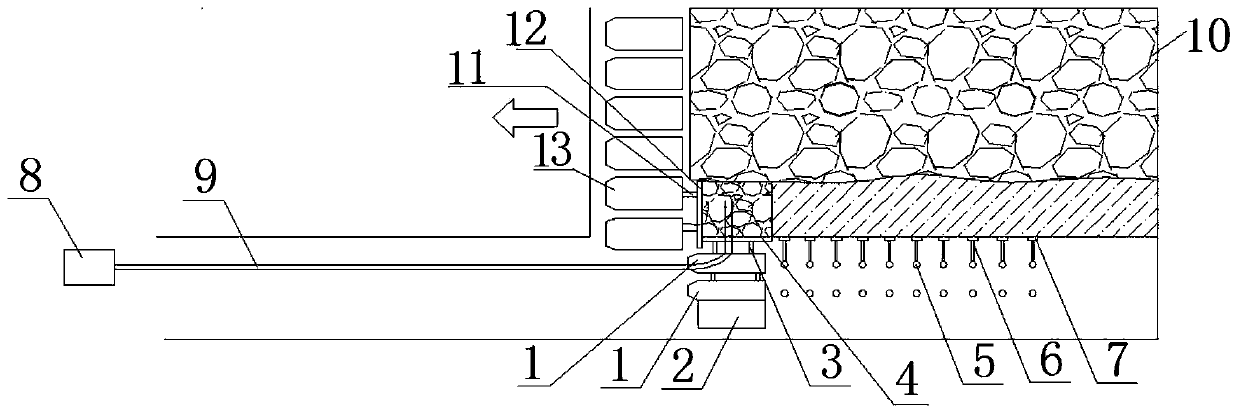

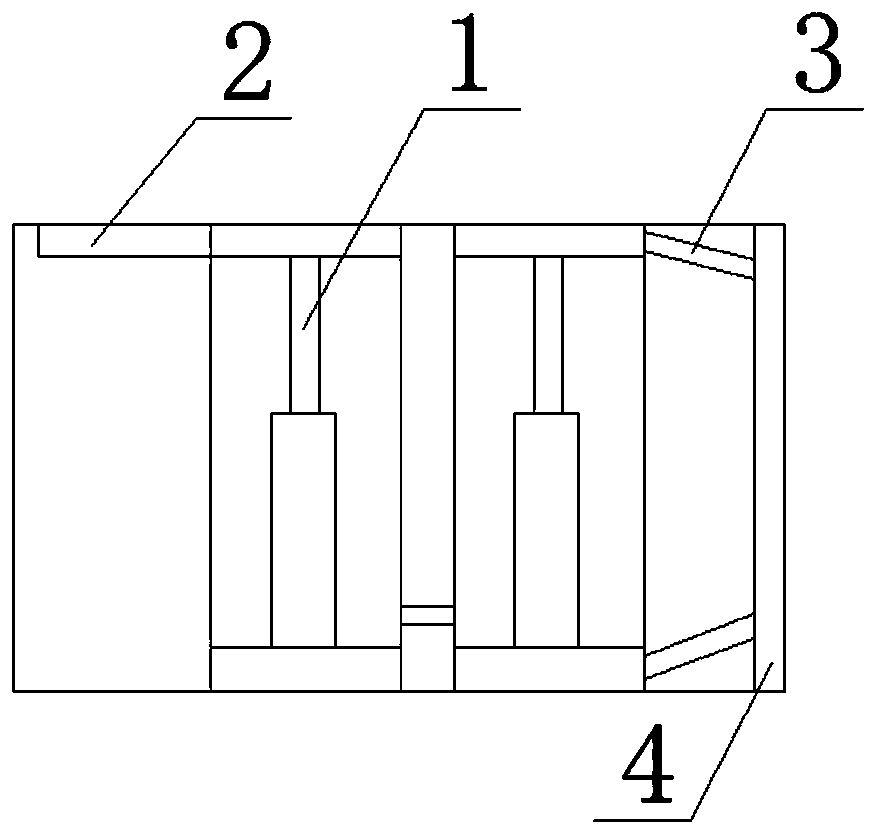

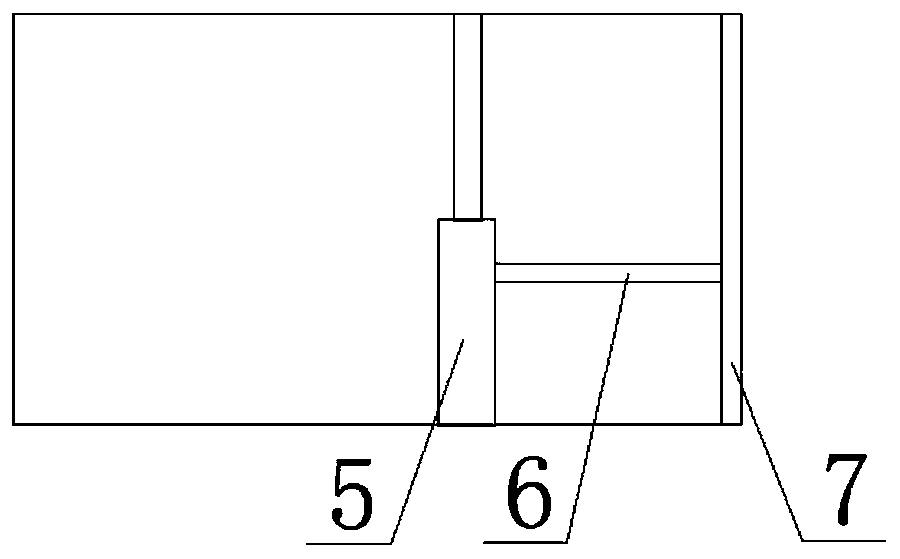

[0027] Such as Figure 1~3 As shown, a gobside entry retention system in which gangue is cemented into a wall in a side mining area includes: several hydraulic supports 13, a first hydraulic jack 11, a first gangue retaining plate 12, a retaining support, and a second hydraulic jack 3 , the second baffle plate 4 and the grouting pumping station 8, the specific introduction is as follows:

[0028] The hydraulic support 13 is used to maintain the roof of the working face, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com