Tea packaging machine

A technology for tea bags and heat-sealing devices, applied in the directions of packaging, transportation packaging, transportation and packaging, etc., can solve the problems of uneven cutting, high stacking height of tea leaves, uneven throwing, etc., to reduce steps, save time, and use handy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

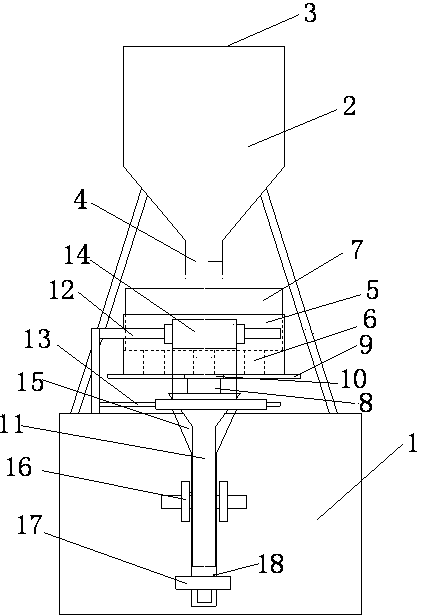

[0012] The preferred technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings.

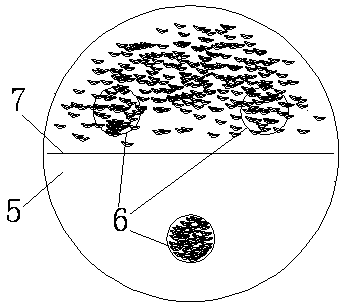

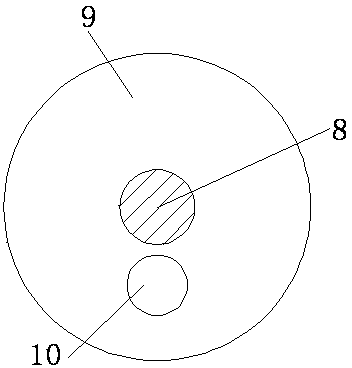

[0013] As shown in the figure, the tea packaging machine of the present invention includes a workbench 1 and a hopper 2 that can adjust the size of the discharge port. The top of the hopper 2 is a feed port 3, and the bottom of the hopper 2 is a discharge port 4. The hopper 2 is fixed on the workbench 1, a rotating unloading tray 5 is arranged below the discharge port 4, and three storage cavities 6 are evenly arranged on the same circumference at the bottom of the unloading tray 5 , the storage cavity 6 is a cylindrical through hole, and a vertical scraper 7 is arranged in the middle of the blanking tray 5, and the blanking tray 5 is fixed on the workbench 1 by a fixed shaft 8 , a baffle plate 9 is also fixed on the fixed shaft 8, the baffle plate 9 is located below the feeding tray 5, and is close to the bottom of the feeding tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com