Self-cleaning washing machine

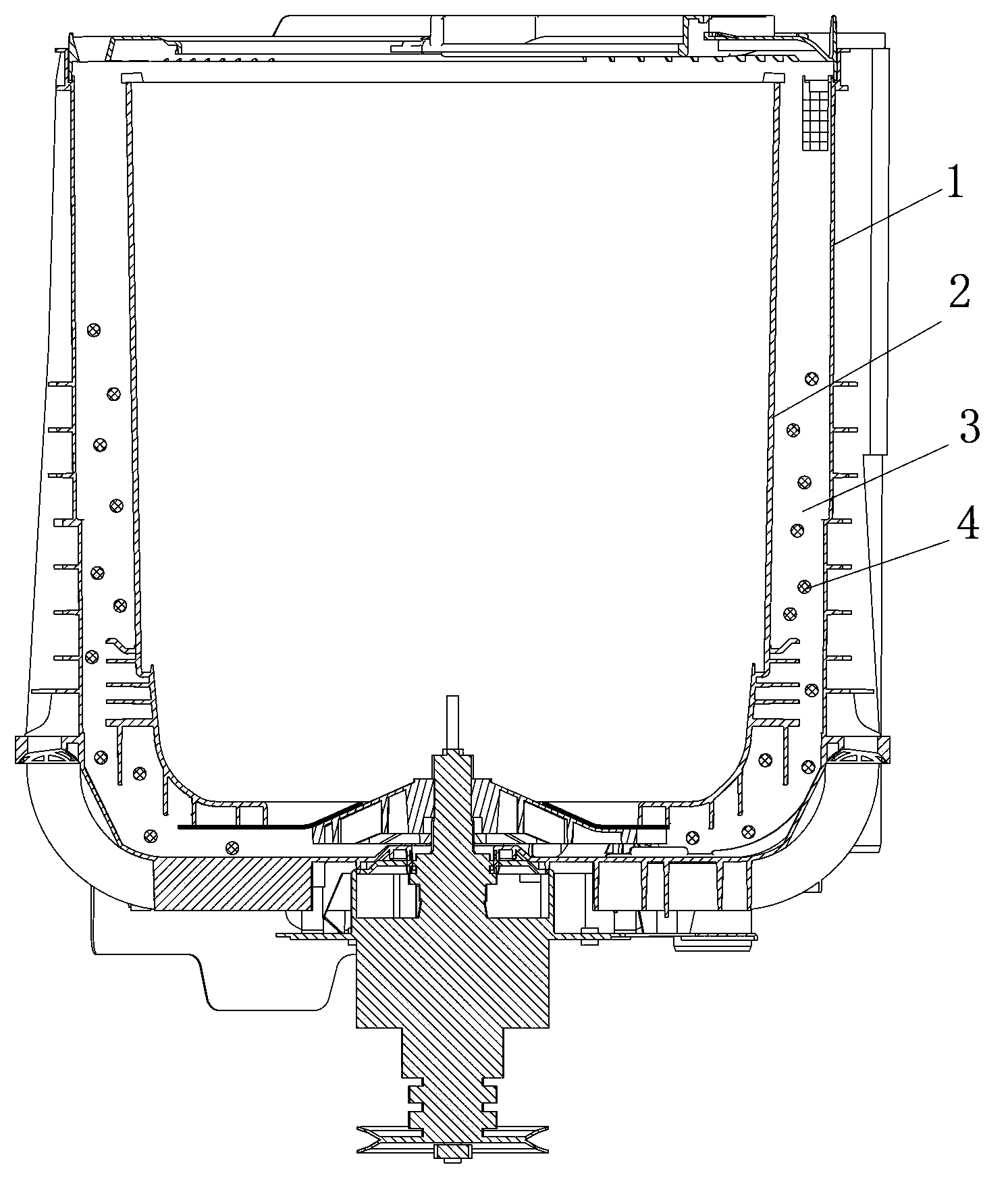

A washing machine and self-cleaning technology, applied in the field of washing machines, can solve problems such as difficult to handle, residual particles, and the inability of cleaning particles to achieve self-cleaning of the bottom of the inner tub, so as to prevent the growth of bacteria and prevent dirt.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

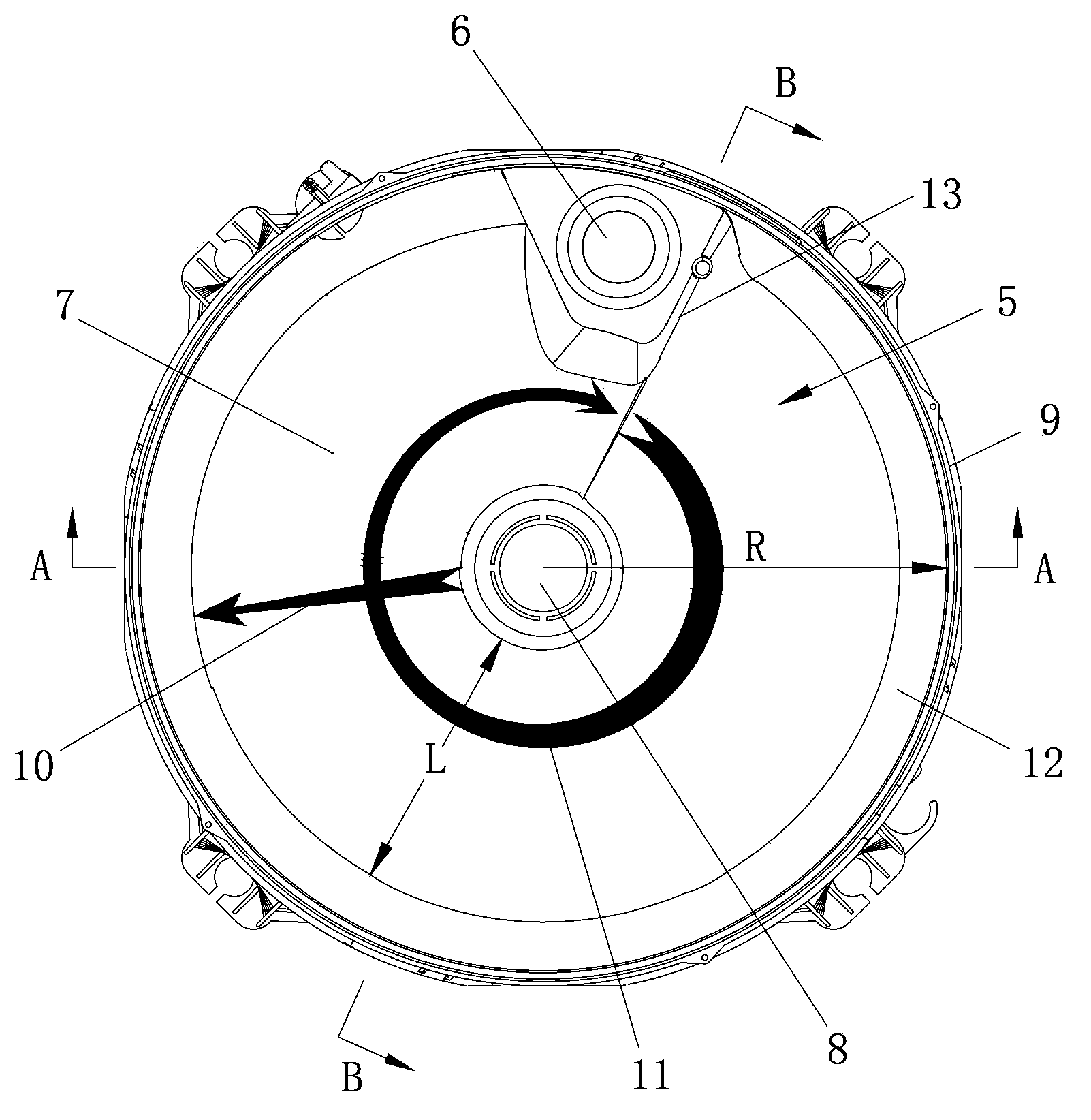

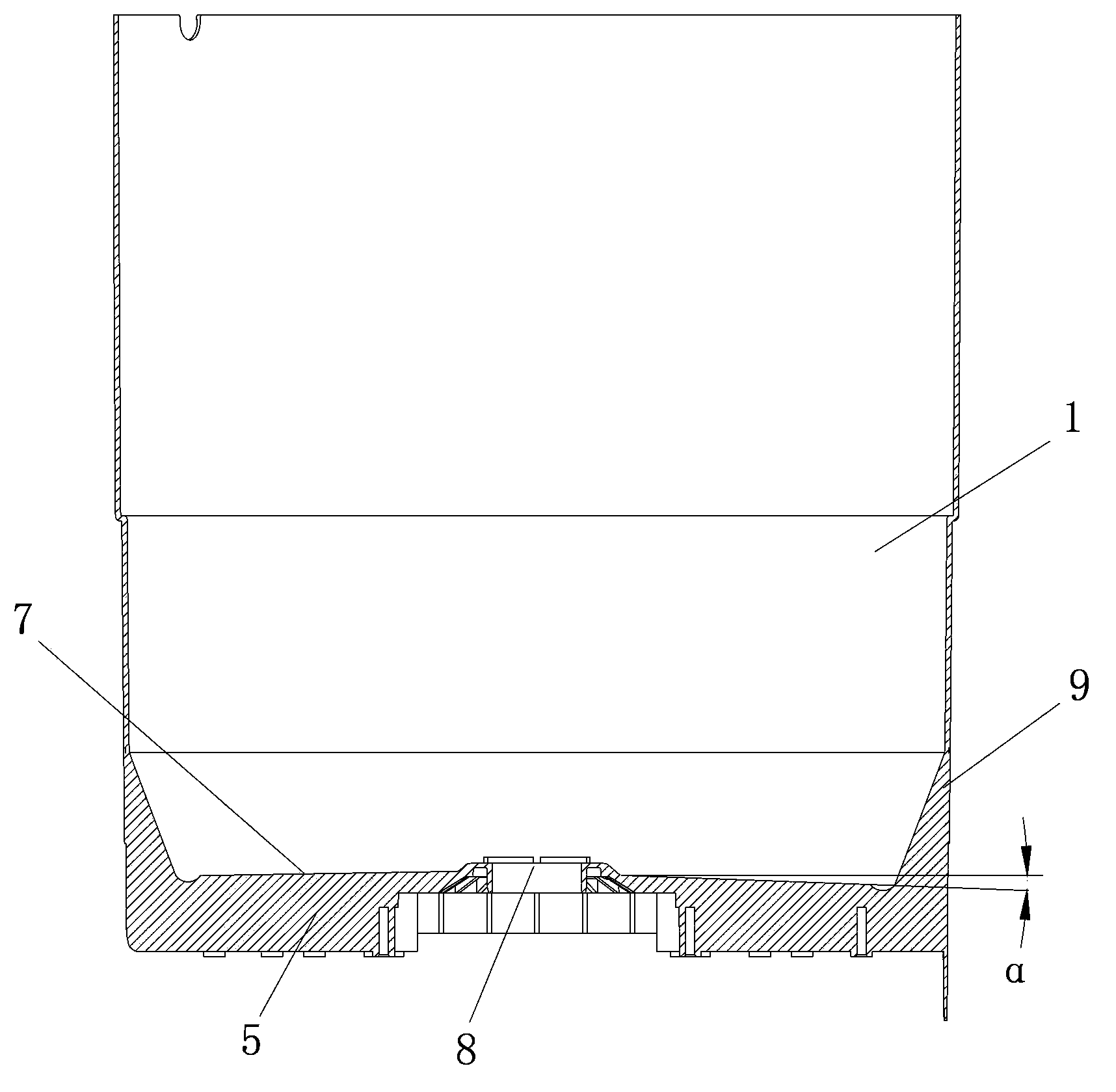

[0041] Such as figure 2 and image 3 As shown, in the present embodiment, the improvement of the bottom of the outer bucket is specifically: the surface of the bottom of the outer bucket is inclined from the center 8 of the bottom of the outer bucket radially toward the side wall 9 of the outer bucket. There is a surface inclined area 7, which is set along the circumferential direction, and the height near the center 8 of the outer tub is higher than the height near the side wall 9 of the outer tub, and the washing machine drain 6 is located at the lowest point at the bottom of the outer tub. This structure is good for drainage, especially when the amount of water in the later stage of drainage is small, the drainage water will wash the cleaning particles into the drainage outlet.

[0042] The surface inclined area 7 is a structure that gradually decreases from the center 8 of the outer barrel bottom to the edge. Specifically, the height of the inner surface of the outer bar...

Embodiment 2

[0045] Such as figure 2 and Figure 4 As shown, in this embodiment, the improvement of the bottom of the outer bucket is specifically: an inclined and gradually lower structure 11 along the circumferential direction consistent with the dehydration rotation direction of the inner bucket, and the height of the inner surface of the bottom of the outer bucket 5 gradually decreases clockwise or counterclockwise along the circumferential direction, The gradually lowering direction is consistent with the rotation direction of the inner tub of the washing machine when dehydrating. Generally, the dehydration rotation direction of the inner barrel of the existing washing machine is clockwise, so the height of the inner surface of the outer barrel bottom 5 gradually decreases clockwise (see figure 2 ), the drain port 6 is located at the lowest point 14 at the bottom of the outer barrel, and one side is adjacent to the highest point 15. This structure is not only conducive to the disc...

Embodiment 3

[0048] This embodiment is a combination of Embodiment 1 and Embodiment 2. The change of the height of the inner surface of the bottom of the outer bucket is: while gradually decreasing from the center radially outward, it also gradually decreases along the circumferential direction. This structure is more conducive to drainage. The cleaning particles are discharged into the drain with the water flow.

[0049] The above-mentioned embodiments have the inner surface of the bottom of the outer bucket with an inclined structure, and the potential energy brought by the slope height difference is converted into flow energy of water, so as to increase the impact force of the water flow and prevent cleaning particles from remaining on the inner surface of the bottom of the outer bucket.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com