On-line heating tension straightening device and straightening method for titanium alloy wire

A technology of titanium alloy wire and tension, which is applied in the field of on-line heating tension straightening of titanium alloy wire and on-line heating tension straightening device of titanium alloy wire, which can solve the problems of low heating efficiency and large tension fluctuation range, and achieve improved heating High efficiency, high degree of automation, and the effect of improving straightening efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

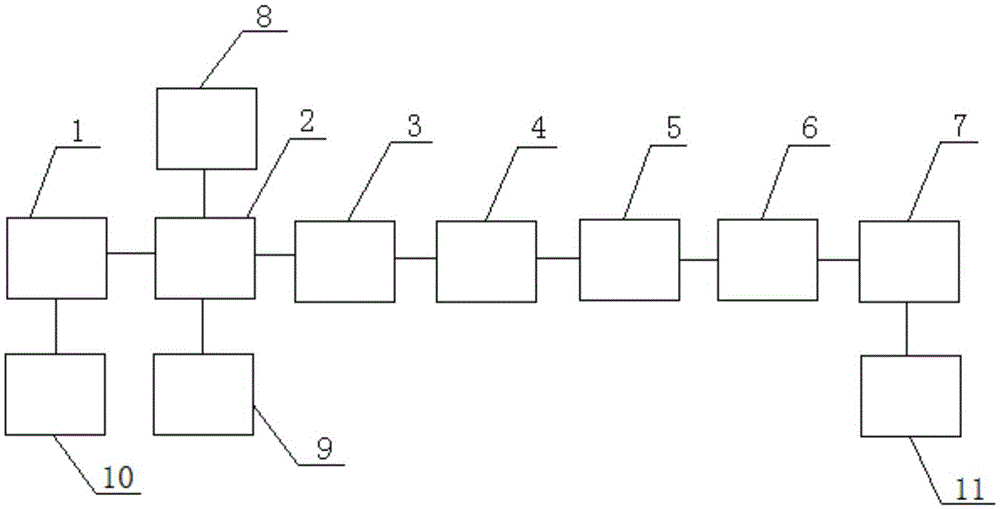

Embodiment 1

[0056] Start the tube furnace 4 to raise the temperature to 720°C, start the submerged tank type circulating water cooling device 5; thread the titanium alloy wire into the active pay-off machine 1, and the titanium alloy wire from the active pay-off machine 1 enters the tension frame 2, Apply a straightening tension of 70N to the wire, and the linear potentiometer 9 generates a position signal and transmits it to the pay-off frequency converter 10, thereby controlling the pay-off speed of the active pay-off machine 1 to adapt to the take-up speed of the active take-up machine 7; The titanium alloy wire coming out of the rack 2 enters the induction furnace 3 and is rapidly heated to 400°C, and then enters the tube furnace 4 and continues to heat up to 720°C; the titanium alloy wire coming out of the tube furnace 4 enters the immersion tank In the type circulating water cooling device 5, the titanium alloy wire is quickly and fully cooled and dried through the trough-type immers...

Embodiment 2

[0058] Start the tube furnace 4 to heat up to 760°C, start the submerged tank type circulating water cooling device 5; thread the titanium alloy wire into the active pay-off machine 1, and the titanium alloy wire from the active pay-off machine 1 enters the tension frame 2, Apply a straightening tension of 300N to the wire, and the linear potentiometer 9 generates a position signal and transmits it to the pay-off frequency converter 10, thereby controlling the pay-off speed of the active pay-off machine 1 to adapt to the take-up speed of the active take-up machine 7; The titanium alloy wire coming out of the tension frame 2 enters the induction furnace 3 and is rapidly heated to 440°C, and then enters the tube furnace 4 to continue heating to 760°C; the titanium alloy wire coming out of the tube furnace 4 enters the immersion furnace In the trough-type circulating water cooling device 5, the titanium alloy wire is rapidly and fully cooled and dried through the trough-type immer...

Embodiment 3

[0060] Start the tube furnace 4 to heat up to 800°C, start the submerged tank-type circulating water cooling device 5; thread the titanium alloy wire into the active pay-off machine 1, and the titanium alloy wire from the active pay-off machine 1 enters the tension frame 2, Apply a straightening tension of 600N to the wire, and the linear potentiometer 9 generates a position signal and transmits it to the pay-off frequency converter 10, thereby controlling the pay-off speed of the active pay-off machine 1 to adapt to the take-up speed of the active take-up machine 7; The titanium alloy wire coming out of the tension frame 2 enters the induction furnace 3 and is rapidly heated to 480°C, and then enters the tube furnace 4 to continue heating up to 800°C; the titanium alloy wire coming out of the tube furnace 4 enters the immersion furnace In the trough-type circulating water cooling device 5, the titanium alloy wire is rapidly and fully cooled and dried through the trough-type im...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com